Introduction

The internal combustion engine, a vital component of modern machinery, operates on two primary types of cycles: 2-stroke vs. 4-stroke. These engines differ in their number of strokes per working cycle, impacting their performance, efficiency, and applications. Whether in automotive, marine, or industrial machinery, understanding the distinctions, advantages, and limitations of 2-stroke and 4-stroke engines is essential for making informed decisions about their use. This article will delve into these differences and explore how each type suits specific needs and industries.

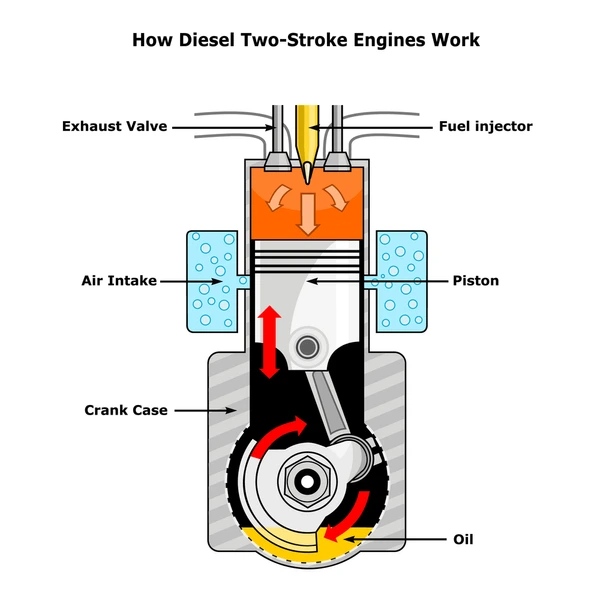

What is a 2-Stroke Engine?

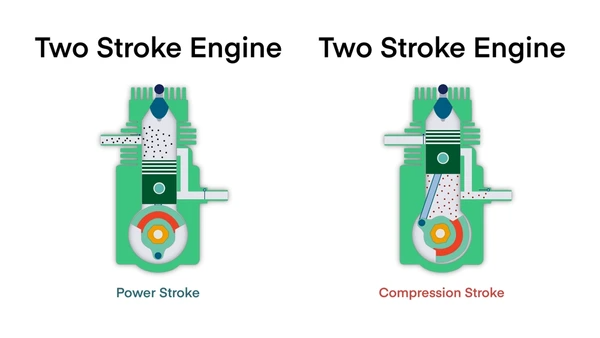

A two-stroke engine completes a power cycle in just two piston strokes during a single revolution of the crankshaft. Unlike four-stroke engines, which require four strokes per cycle, two-stroke engines combine simplicity and power efficiency. The process is streamlined into the compression stroke and the power stroke, making it unique in its operation.

Working Principles

- Compression Stroke:

In this stage, the piston moves upward from the bottom dead center (BDC) to the top dead center (TDC), compressing the air-fuel mixture. This mixture, supplied by a carburetor or fuel injection system, is critical for efficient combustion. - Power Stroke:

The power stroke begins when the spark plug ignites the compressed air-fuel mixture, causing an explosion. This rapid expansion forces the piston downward to BDC, generating mechanical energy that drives the crankshaft. - Scavenging Process:

A defining feature of two-stroke engines, scavenging involves expelling exhaust gases and introducing a fresh air-fuel mixture simultaneously. Ports in the cylinder walls open and close as the piston moves, facilitating this process. However, scavenging can allow some unburned fuel to escape with exhaust gases, contributing to higher emissions compared to other engine types.

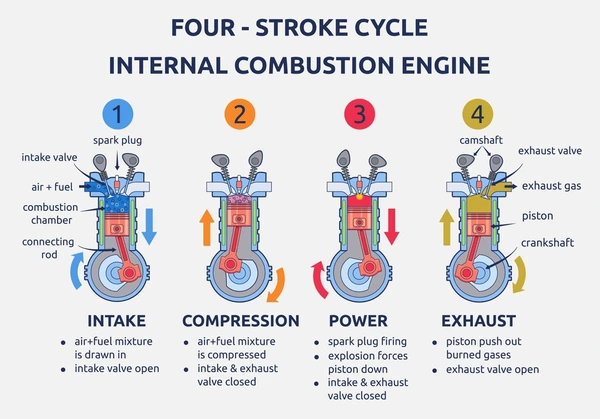

What is a 4-Stroke Engine?

A 4-stroke engine, also called a four-cycle engine, operates with four distinct piston strokes: intake, compression, power, and exhaust. Each stroke contributes to the engine’s efficient power generation and seamless operation.

Working Principle

- Intake Stroke:

This stroke begins with the piston at the top dead center (TDC) and ends at the bottom dead center (BDC). As the intake valve opens, the piston moves downward, creating a vacuum that draws the air-fuel mixture into the cylinder. During this process, the exhaust valve remains closed, ensuring the cylinder fills with the mixture needed for combustion. - Compression Stroke:

Starting at BDC, the piston moves upward, compressing the air-fuel mixture until it reaches TDC. Both intake and exhaust valves remain closed during this stroke. Compression raises the mixture’s temperature and pressure, optimizing conditions for ignition and enhancing engine efficiency. - Power (Combustion) Stroke:

Following compression, the spark plug ignites the air-fuel mixture (in gasoline engines), or the high compression generates enough heat for ignition (in diesel engines). The resulting explosion forces the piston downward from TDC to BDC, delivering the mechanical energy that powers the crankshaft. The intake and exhaust valves stay closed to contain the combustion forces. - Exhaust Stroke:

In the final stroke, the piston moves upward from BDC to TDC, expelling the burnt gases through the open exhaust valve. The intake valve remains closed during this process, ensuring the cylinder is clear and ready for the next intake stroke.

2-Stroke vs. 4-Stroke Engines: Key Differences Explained

Mechanical Differences

- Power Cycle Completion:

A 2-stroke engine completes a power cycle in just two strokes—one upward and one downward motion of the piston—per crankshaft revolution. In contrast, a 4-stroke engine requires four strokes (intake, compression, power, and exhaust) to complete a cycle, taking two crankshaft revolutions. - Components and Complexity:

2-stroke engines are simpler, with fewer moving parts and no poppet valves, valve trains, or camshafts, resulting in a lighter and more compact design. In comparison, 4-stroke engines include these additional components, making them more complex and heavier. - Lubrication:

2-stroke engines rely on oil mixed with fuel for lubrication, simplifying their design but increasing exhaust emissions. Meanwhile, 4-stroke engines use a separate lubrication system, which is more efficient and environmentally friendly.

Performance Characteristics

- Power-to-Weight Ratio:

2-stroke engines deliver a higher power-to-weight ratio thanks to their simpler design and fewer components, making them ideal for lightweight applications like motorcycles and small tools. - Fuel Efficiency:

4-stroke engines are more fuel-efficient due to their separate intake and exhaust strokes, which ensure better combustion and reduced fuel wastage. - Torque and Power Output:

2-stroke engines generate more uniform torque and higher specific power output with a power stroke every revolution. However, they tend to consume more fuel and produce higher emissions. - Emissions:

4-stroke engines produce fewer emissions because their design allows for more complete combustion. In contrast, 2-stroke engines often expel unburned fuel, leading to higher pollution levels.

Advantages and Disadvantages

- 2-Stroke Engines:

Advantages: Lightweight, simple design, and lower manufacturing costs make them ideal for high-speed operations and compact devices.

Disadvantages: High emissions, reduced fuel efficiency, and faster wear and tear due to the lack of a dedicated lubrication system. - 4-Stroke Engines:

Advantages: Superior fuel efficiency, lower emissions, and greater durability due to a separate lubrication system. Perfect for sustained power needs in vehicles and industrial equipment.

Disadvantages: More complex, heavier, and costlier to manufacture compared to 2-stroke engines.

Applications

- 2-Stroke Engines:

These engines are commonly found in motorcycles, chainsaws, and handheld tools where weight and simplicity are critical. - 4-Stroke Engines:

Primarily used in automobiles, trucks, and industrial machinery, where efficiency, durability, and reduced emissions are essential.

FAQ: Common Questions About 2-Stroke and 4-Stroke Engines

Can 2-stroke engines be used for vehicles?

- Yes, but they are less common due to their higher emissions and fuel consumption compared to 4-stroke engines.

What are the maintenance requirements for 2-stroke vs. 4-stroke engines?

- 2-stroke engines require frequent maintenance due to their simple design and faster wear. 4-stroke engines need less frequent maintenance and have longer service intervals.

Why do 2-stroke engines produce more emissions?

- 2-stroke engines burn oil mixed with fuel, resulting in incomplete combustion and higher emissions.

In what applications are 2-stroke engines commonly used?

- 2-stroke engines are commonly found in applications where a high power-to-weight ratio is beneficial, such as in chainsaws, outboard motors, and some motorcycles.

To get detailed scientific explanations of 2-stroke vs. 4-stroke engines, try Patsnap Eureka.