304 stainless steel is the world’s most widely used stainless alloy. As an austenitic chromium-nickel steel, it offers excellent corrosion resistance, strong mechanical performance, and superb formability. You’ll find it in kitchen sinks, surgical tools, exhaust systems, and skyscraper panels.

This blog explores 304 stainless steel’s composition, performance, industry applications, and technological advancements. It also highlights how the PatSnap Eureka AI Agent empowers users to explore innovation trends, material substitutes, and competitive intelligence in real time.

What is 304 Stainless Steel?

304 stainless steel, sometimes called 18-8 stainless, contains approximately 18% chromium and 8% nickel. This combination forms a protective oxide layer that resists oxidation, corrosion, and chemical attack. As a result, it is used in environments ranging from kitchens and hospitals to chemical plants and construction sites.

Composition & Properties / Performance

Chemical Composition (% by weight)

| Element | Content |

|---|---|

| Chromium (Cr) | 18.0–20.0 |

| Nickel (Ni) | 8.0–10.5 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Key Mechanical & Physical Properties

- Density: 7.93 g/cm³

- Melting Range: 1,400 – 1,450 °C

- Tensile Strength: ~515 MPa

- Yield Strength: ~205 MPa

- Elongation: ≥ 40%

- Modulus of Elasticity: 193 GPa

- Thermal Conductivity: 16.2 W/m·K

- Electrical Resistivity: 0.72 µΩ·m

- Magnetic: Non-magnetic in annealed state

Material Grades & Designations

| Standard | Grade Name |

|---|---|

| ASTM | A240, A276, A312 |

| UNS | S30400 |

| EN/DIN | 1.4301 |

| JIS | SUS304 |

| ISO | X5CrNi18-10 |

Global Equivalents

| Region | Equivalent Grade |

|---|---|

| USA | ASTM A240 304 |

| Europe | EN 1.4301 |

| China | GB 06Cr19Ni10 |

| Japan | JIS SUS304 |

Application Landscape

304 stainless steel’s appeal lies in its adaptability. It performs reliably in humid, mildly acidic, and even industrially aggressive settings, making it a go-to material in both mass-market and mission-critical applications.

Industry Sectors & Use Cases

- Food & Beverage

- Sinks, counters, dishwashers, brewing tanks, milk storage vats

- Non-reactive surface ensures hygiene and ease of cleaning

- Approved for food-contact under FDA and EU regulations

- Architecture & Construction

- Exterior cladding, elevator panels, railings, handrails, structural supports

- Maintains appearance even in coastal or polluted environments

- Used in high-profile buildings like airports and stadiums

- Medical & Healthcare

- Surgical trays, orthopedic tables, IV poles, bed frames

- Sterilizable and biologically inert for non-implant applications

- Automotive & Transportation

- Trim, grills, mufflers, exhaust manifolds

- Withstands vibration, corrosion, and heat cycling

- Chemical & Industrial Processing

- Piping, storage tanks, heat exchangers

- Handles chemicals like nitric acid and dilute organic acids

- Consumer Products

- Cookware, thermoses, watches, washing machine drums

- Aesthetic finish and corrosion resistance boost product longevity

Emerging Trends

- Hydrogen infrastructure: Early-stage studies show 304’s potential in low-pressure hydrogen distribution lines

- 3D printing (metal AM): Adapted into stainless steel powder for laser powder bed fusion and binder jetting

- Sustainability demand: Chosen for low-maintenance and long service life in eco-conscious buildings

- Smart manufacturing: Incorporated in modular factory components that require durability and hygiene

304 Stainless Steel vs Other Similar Materials

| Property | 304 SS | 316 SS | 430 SS |

|---|---|---|---|

| Nickel Content | ~8% | ~10–14% | ~0% |

| Corrosion Resistance | High | Excellent (marine) | Moderate |

| Magnetic | Non-magnetic | Non-magnetic | Magnetic |

| Cost | Moderate | Higher | Lower |

| Ideal Use | Food, general | Marine, chemical | Indoor decor |

Advantages of 304 Stainless Steel

- Excellent resistance to oxidation and many acids

- Non-magnetic and easy to form, bend, and weld

- Readily available and globally standardized

- Long-lasting with minimal maintenance

- 100% recyclable with no degradation in quality

- Suitable for both decorative and load-bearing purposes

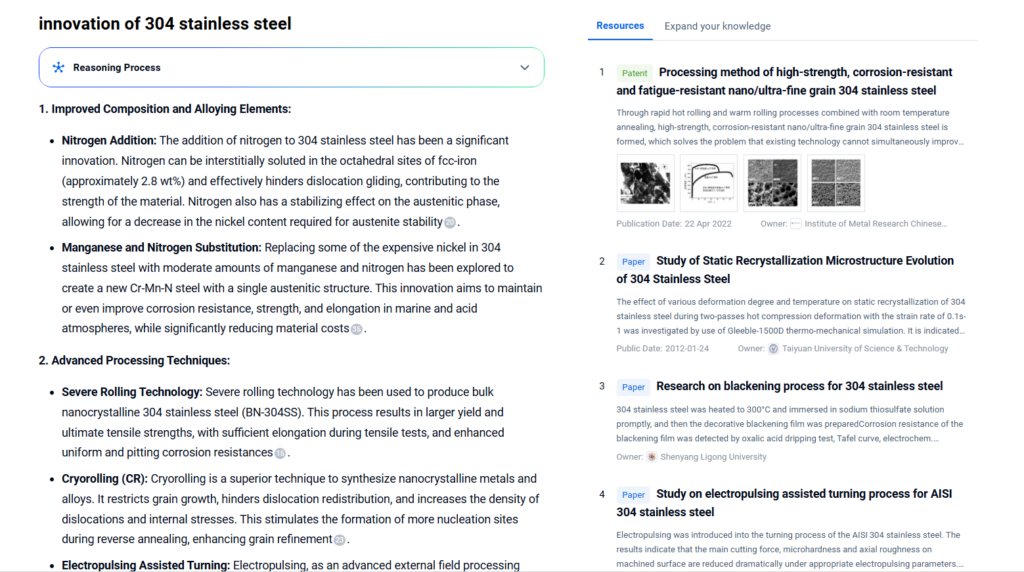

Innovations & Technology

Recent R&D Advances

- Additive Manufacturing

- LPBF and DMLS methods have enabled production of complex, topology-optimized 304 components

- Powder metallurgy improvements have reduced defects and improved density for 3D-printed parts

- Surface Engineering

- New electropolishing techniques reduce surface roughness for improved hygiene

- Plasma nitriding and nano-coatings extend service life in aggressive environments

- Corrosion Modeling

- AI-assisted simulations predict long-term performance in saline and acidic media

- Multiphysics models integrate temperature, humidity, and load data to estimate lifespan

- Low-Nickel Formulations

- Development of leaner variants with comparable corrosion resistance

- Addressing raw material price volatility and supply risks

Sustainability & Environmental Impact

- Made from up to 60% recycled stainless scrap

- 100% recyclable at end of life with closed-loop remelting

- Long service life reduces replacement frequency and resource use

- Complies with REACH, RoHS, FDA food safety, and LEED construction standards

- Carbon emissions mainly from nickel and chromium mining; new low-carbon melt processes under study

PatSnap Eureka AI Agent Capabilities

PatSnap Eureka AI Agent helps users:

- Discover technical breakthroughs in corrosion resistance and welding

- Monitor competitor patent filings in specialty stainless alloys

- Identify white space in sustainable alloy development

- Analyze global production hubs and material flows

- Stay informed about nickel price trends and substitution strategies

Conclusion

304 stainless steel continues to dominate due to its perfect balance of affordability, performance, and global availability. Its applications span across sectors and environments, from factory floors to food courts and skyscrapers.

As new challenges emerge—whether sustainability, supply security, or material performance—engineers and product developers can rely on tools like PatSnap Eureka AI Agent to uncover new solutions, optimize selection, and outpace the competition.

FAQs

No, it’s non-magnetic when annealed. Cold working can introduce slight magnetism.

It resists most corrosion but may develop surface rust in highly saline or acidic environments.

Yes. 304 is widely used in food processing and cooking equipment due to its hygiene and non-reactivity.

316 includes molybdenum, giving it superior resistance to chlorides, especially in marine or coastal settings.

Yes. It’s fully recyclable without loss of quality and often contains a high percentage of recycled content.

For more scientific explanations of 304 stainless steel , try PatSnap Eureka AI Agent.