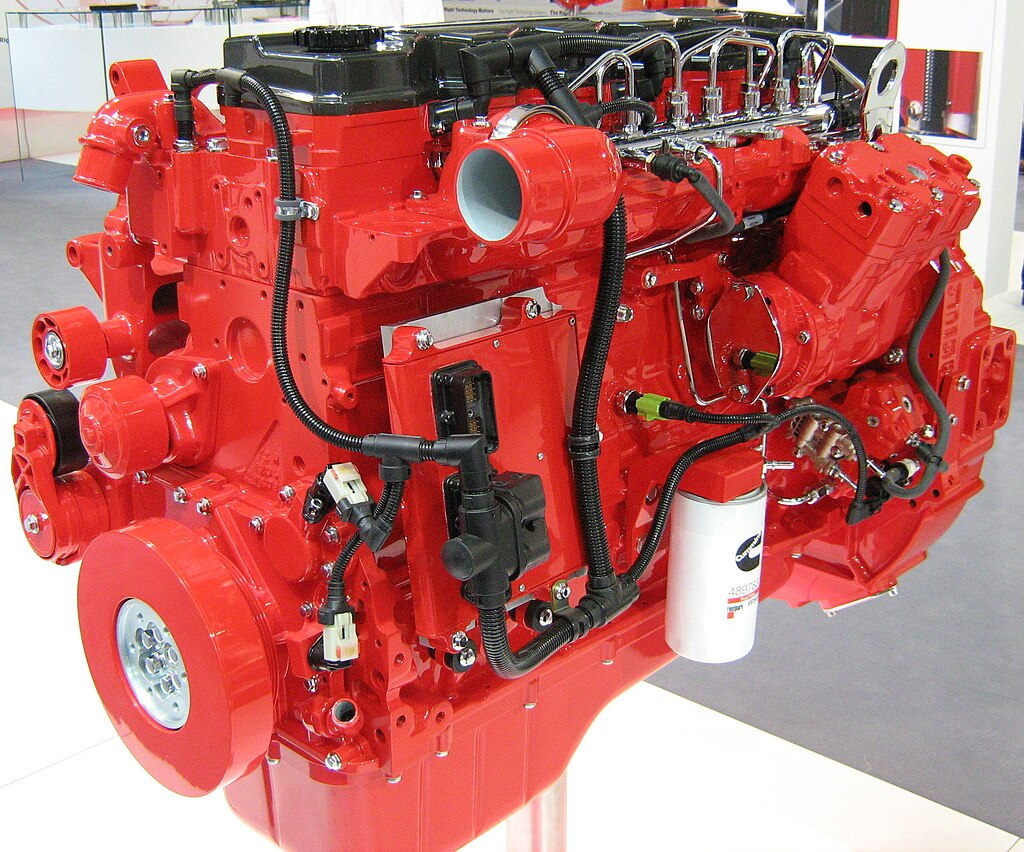

Cummins engines have earned a strong reputation as a leader in the diesel engine industry. Known for their innovation, reliability, and exceptional performance, 5.9 Cummins engines power a wide range of vehicles and equipment. Whether you need fuel efficiency, durability, or raw power, the 5.9 Cummins engine offers a trusted solution for various applications.

History of Cummins Engines: From the 4BT to the ISX

- 4BT Engine

The 4BT engine, also known as the 3.9L 4-cylinder, belongs to the ISB series. It is considered a predecessor to the ISX engine. Often found in Dodge diesel models, the 4BT was also used in older Jeep Wrangler models. - 6BT Engine

The 6BT engine, with its 12-valve configuration, is another variant in the ISB series. It differs from the 4BT due to its higher cylinder count, which improves both power and efficiency. - ISX Engine

The ISX engine marks a significant advancement in Cummins’ lineup. Designed for heavy-duty trucks, it boasts a 15L displacement, making it larger than the 4BT and 6BT engines. The ISX delivers enhanced performance and reliability, perfect for long-haul trucking needs. - Dataplate and Serial Number Lookup

All Cummins engines, including the 4BT, 6BT, and ISX, have a dataplate with essential engine details. Located on top of the engine, this plate includes serial numbers and specifications, making engine identification and lookup easy.

Key Features of the 5.9 Cummins Engine

- Engine Configuration and Displacement

The 5.9 Cummins engine is an inline 6-cylinder with a displacement of 5.9 liters (359 cubic inches). This configuration strikes a balance between power and efficiency, making it ideal for both on-road and off-road use. - Power and Performance

The engine delivers impressive horsepower and torque, making it perfect for towing heavy loads and tackling tough terrains. - Fuel Efficiency

Despite its powerful performance, the engine offers good fuel efficiency for a diesel of its time. This efficiency comes from its advanced fuel injection system and thoughtful engine design. - Emission Control

Emission control technologies help minimize the environmental impact of the engine. For example, adding ethanol to the fuel blend reduces particulate matter emissions by 20% with 10% ethanol and 30% with 15% ethanol, without affecting NOx emissions. - Compatibility and Integration

The engine fits seamlessly into various vehicles, especially Dodge Ram trucks. It integrates easily, ensuring optimal performance and reliability.

- Availability and Market Presence

The engine enjoys strong market presence, with many remanufactured and used options available online. This availability makes it a popular choice for those seeking a reliable diesel engine replacement. - Warranty and Support

Many sellers offer warranty protection on these engines, providing up to 3 years of coverage. This warranty assures buyers of the engine’s quality and performance.

Technological Innovations in Cummins Engines

- Connectivity-Enabled X15 Efficiency Series Engine

In 2020, Cummins introduced the connectivity-enabled X15 Efficiency series engine. This innovative engine showcases Cummins’ commitment to providing advanced technologies that improve both efficiency and performance. - Endurant™ HD Series

Alongside the X15, Cummins launched the Endurant™ HD series, designed for heavy-duty trucking. This series emphasizes durability and reliability, making it ideal for long-haul trucking applications. - Electronic Synchronizer for Multiple Engines

Cummins developed an electronic synchronizer system to control multiple internal combustion engines. This system uses a master engine and slave engines, optimizing fueling to synchronize engine operations. - Cylinder Pressure-Based Control of Dual-Fuel Engines

Cummins explored dual-fuel engine technology, allowing engines to run on different fuel types based on conditions. The cylinder pressure-based control system manages fuel substitution rates, boosting performance and reducing emissions. - Intake Port Throttling Control

For dual-fuel engines with asymmetric intake passages, Cummins created systems to control intake flow. This system adjusts charge flow characteristics to optimize engine performance. - EGR and Blow-By Flow System

Cummins implemented advanced gas flow networks in turbocharged diesel engines. This system blends EGR or blow-by gas with fresh charge air, improving engine efficiency and emissions control. - Air Intake Heater System

To enhance cold weather starts and reduce white smoke emissions, Cummins developed an air intake heater system. This system uses a microprocessor controller to manage heating elements efficiently. - Fast Torque Response for Boosted Engines

Cummins focused on improving turbocharged engine performance through fast torque response technologies. These systems reduce turbo lag by adjusting firing density and compressor pressure ratios, enhancing engine operation.

Application of the 5.9 Cummins Engine

Automotive Applications

The 5.9 Cummins engine is best known for powering Dodge pickup trucks, particularly the Ram series. This partnership began in 1989 and has become legendary for its durability and power. The engine’s high torque, fuel efficiency, and longevity make it a favorite among truck owners and enthusiasts.

Broader Industrial Use

Beyond automotive applications, the 5.9 Cummins engine is also used in industrial and agricultural sectors. Its reliability and durability make it a trusted choice across various industries.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| 5.9L Cummins B Series Engine Cummins Inc. | Demonstrated ability to run on ethanol-diesel blends with reduced particulate matter emissions. | Heavy-duty diesel applications in the automotive, industrial, and agricultural sectors. |

| Dodge Ram Pickup Trucks Cummins Inc. | Robust and durable 5.9L diesel engine known for high torque, fuel efficiency, and longevity. | Powering full-size pickup trucks for demanding towing and hauling tasks. |

Upgrading and Modifying the 5.9 Cummins Engine

Common Upgrades

- Fuel System Upgrades

A popular upgrade for the 5.9L Cummins engine is a fuel pump, like the Fass pump. This improves the common rail fuel system’s sensitivity and filtration. - Cooling System Enhancements

As more power generates more heat, upgrading the cooling system is crucial. This prevents damage to the pistons, improving engine reliability and longevity.

Performance Modifications

- Turbocharger Upgrades

Upgrading the turbocharger can boost power output and efficiency significantly. - Exhaust System Modifications

An upgraded exhaust system reduces backpressure and enhances engine performance. - Intake System Upgrades

Improving the air intake system allows more air into the engine, which increases power.

Reliability and Longevity

- Oil and Filter Upgrades

Using high-quality oil and filters can increase engine durability and performance. - Cooling System Enhancements

As mentioned, upgrading the cooling system is essential to prevent overheating and protect engine components.

Aftermarket Support and Modifications

- Electronic Control Unit (ECU) Tuning

Reflashing the ECU optimizes engine performance and efficiency, unlocking more potential. - Camshaft and Valve Train Upgrades

These upgrades improve airflow and combustion efficiency, leading to better overall performance.

Considerations for Upgrades

- Compatibility and Warranty

Before upgrading, check compatibility to avoid voiding warranties. Some aftermarket parts may require professional installation to maintain warranty coverage. - Professional Installation

For complex modifications, always seek professional installation. This ensures proper fitment and functionality.

To get detailed scientific explanations of 5.9 Cummins, try Patsnap Eureka.