Technical Background and Objectives

Background

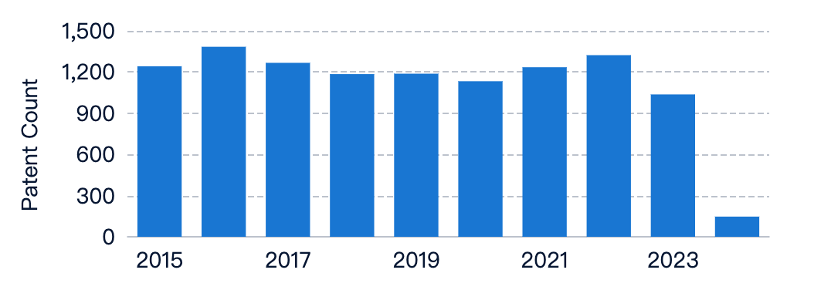

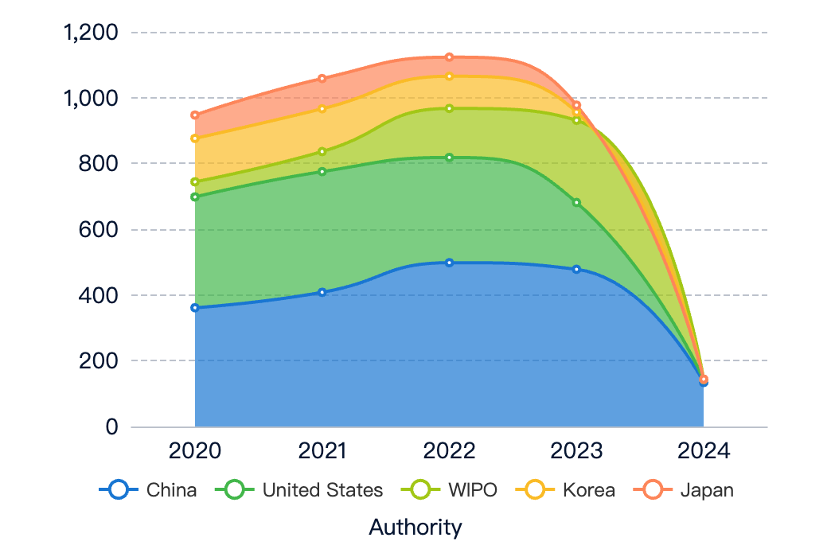

In the technical field of ‘ammonia engine high thermal efficiency,’ patent applications have shown a relatively stable trend with fluctuations but no significant changes, indicating consistent research and development activity without major breakthroughs. However, the number of related literature publications has shown an overall upward trend, especially in recent years, suggesting increasing academic interest and research activities. This indicates that the field is in an exploratory stage, with practical applications and commercialization still facing challenges.

Objectives

The primary objective is to investigate and develop innovative strategies to enhance the thermal efficiency of ammonia engines. Ammonia, a carbon-free fuel, has garnered significant attention as a potential alternative to conventional fossil fuels, particularly in the transportation and power generation sectors. This research aims to address the challenges associated with ammonia’s combustion properties by exploring advanced combustion techniques, engine design modifications, and fuel delivery systems tailored specifically for ammonia engines.

To get a detailed scientific explanations of ammonia engine high thermal efficiency, try Eureka.

Technical Current Status Analysis

Ammonia Engines

Ammonia engines, utilizing ammonia as a carbon-free fuel, have attracted widespread attention due to ammonia’s high energy density, ease of storage and transportation, and potential for reducing greenhouse gas emissions. They offer significant benefits in various sectors:

- Transportation: Potential replacement for traditional gasoline and diesel engines, reducing CO2 emissions and addressing challenges associated with electric vehicles’ limited range and long charging times.

- Power Generation: Used in distributed power generation systems, providing reliable energy supply to remote areas with limited access to traditional energy sources.

- Industrial Applications: Utilized in processes requiring high-temperature heat or mechanical power, such as chemical plants, refineries, and manufacturing facilities.

Technical Characteristics and Challenges:

- Combustion Characteristics: Ammonia has a narrower flammability range, higher auto-ignition temperature, and slower burning rate compared to traditional fuels, leading to incomplete combustion and reduced thermal efficiency.

- Engine Design and Materials: Requires specialized designs and materials resistant to ammonia and its combustion byproducts to ensure durability and prevent component degradation.

- Emissions and Aftertreatment: Produces pollutants such as nitrogen oxides (NOx) and unburned ammonia slip, requiring effective aftertreatment systems.

- Fuel Storage and Delivery: High vapor pressure and potential for solid deposits necessitate specialized systems for efficient and reliable fuel delivery.

- Control Systems and Optimization: Advanced control systems and optimization strategies are needed for real-time monitoring and adjustment to achieve optimal combustion and thermal efficiency.

Technological Paths:

- Advanced Combustion Strategies: Develop innovative combustion strategies tailored to ammonia’s unique properties, such as HCCI, RCCI, or dual-fuel combustion modes.

- Engine Design and Materials Research: Conduct extensive research on engine design and materials suitable for ammonia combustion.

- Fuel Injection and Ignition Systems: Develop advanced fuel injection and ignition systems specifically designed for ammonia engines.

- Exhaust After treatment and Emissions Control: Investigate and develop effective exhaust after treatment systems tailored to ammonia engines.

- Integrated System Optimization: Employ advanced modeling, simulation, and optimization techniques to optimize the entire ammonia engine system.

- Control Strategies and Real-Time Optimization: Develop advanced control strategies and real-time optimization algorithms for continuous monitoring and adjustment of engine parameters.

Research Content

Research Objectives

The primary objective is to develop innovative strategies to enhance the thermal efficiency of ammonia engines, focusing on advanced combustion techniques, engine design modifications, and fuel delivery systems. The goal is to create a high-efficiency ammonia engine that can compete with or surpass traditional internal combustion engines while significantly reducing greenhouse gas emissions.

Research Direction and Focus

Advanced Combustion Strategies

- Investigate and optimize advanced combustion strategies for ammonia engines, such as HCCI, RCCI, and dual-fuel combustion strategies.

- Use CFD simulations and experimental validation to evaluate and refine these strategies.

Engine Design Modifications

- Optimize critical components like combustion chamber geometry, fuel injection systems, and ignition systems for ammonia combustion.

- Explore alternative engine configurations such as opposed-piston or free-piston engines.

Fuel Delivery and Handling Systems

- Develop advanced fuel injection strategies, including direct and port injection systems tailored for ammonia.

- Create robust and reliable fuel handling systems encompassing storage, transportation, and on-board delivery mechanisms.

Emissions Reduction and After treatment

- Investigate strategies to mitigate emissions, including advanced EGR techniques, catalytic aftertreatment systems, and ammonia slip control mechanisms.

- Ensure compliance with stringent emissions regulations.

System Integration and Optimization

- Integrate developed technologies into a cohesive and optimized ammonia engine system.

- Conduct comprehensive system-level simulations and experimental validation to assess performance, efficiency, and emissions characteristics.

Collaboration with industry partners, academic institutions, and relevant stakeholders will be crucial for practical applicability and commercial viability.

Technical Development Roadmap

Key Areas of Advancement

- Ammonia Engine Core Technologies: Develop high-efficiency ammonia direct injection systems, ammonia-tolerant combustion chamber materials, and advanced ignition and combustion control mechanisms.

- Emissions Control: Explore selective catalytic reduction techniques, ammonia slip catalysts, and strategies for reducing particulate matter and NOx emissions.

- System Integration: Develop efficient ammonia storage and supply systems and sophisticated control and monitoring systems for seamless integration into various applications.

Main Player Analysis

Key Players and Focus

- Harbin Engineering University: Research on lean premixed combustion characteristics, emissions, and charge motion in marine engines with pre-chamber ignition systems.

- Toyota Motor Corp.: Significant patents on ammonia engine design, combustion systems, fuel injection strategies, and emission control technologies.

- Ford Global Technologies LLC: Patents on optimizing combustion processes, fuel delivery systems, and emission control strategies for ammonia engines.

- Johnson Matthey Plc: Focus on catalytic systems for emission control, particularly SCR catalysts for NOx reduction.

- Shanghai Jiao Tong University: Research on ammonia-diesel dual-fuel engines, trajectory-based combustion control, and combustion optimization in marine engines.

Current Technical Solution Overview

Ammonia Combustion Engines

Ammonia Combustion Engines with Improved Thermal Efficiency: Utilize ammonia as a fuel source and incorporate design features and combustion strategies to enhance thermal efficiency, such as low heat rejection and optimized combustion chamber designs.

Ammonia Engines with Integrated Ammonia Production or Reforming: Produce or reform ammonia on-board for efficient utilization as a fuel, contributing to improved thermal efficiency.

Ammonia-Hydrogen Dual-Fuel Engines: Use a combination of ammonia and hydrogen as fuel sources, leveraging the advantages of both fuels to achieve high thermal efficiency.

High-Efficiency External Combustion Ammonia Engines: Utilize external combustion of ammonia to generate heat for a thermodynamic cycle, potentially offering higher thermal efficiencies compared to internal combustion engines.

Ammonia Engines with Advanced Combustion Systems: Incorporate advanced combustion systems and strategies, such as plasma-assisted combustion, pre-combustion chambers, and optimized injection and ignition systems.

Ammonia Fuel Supply and Storage Systems

Ammonia Fuel Supply Systems: Various systems for storing, handling, and delivering ammonia in liquid or gaseous form to engines, including preheating or vaporizing the ammonia fuel.

Ammonia Fuel Supply Systems for Marine Applications: Designed specifically for marine applications, including storage, handling, and delivery of liquid ammonia fuel.

Dual-Fuel Supply Systems: Handle both ammonia and other fuels, allowing flexible operation and transition between different fuel types.

Ammonia Fuel Supply Systems with Heat Management: Incorporate thermal integration features to preheat or vaporize ammonia fuel, improving system efficiency.

High-Efficiency Ammonia-Fueled Engines: Designed specifically to run on ammonia fuel, incorporating features to improve thermal efficiency and reduce emissions.

Ammonia Cracking and Reforming

Ammonia Cracking Systems: Crack ammonia into hydrogen and nitrogen for use in ammonia engines, using plasma-assisted, catalytic, or thermal cracking methods.

Thermal Integration and Waste Heat Recovery: Incorporate strategies to improve overall efficiency by using engine coolant or exhaust heat to crack or vaporize ammonia.

Exhaust Aftertreatment for Ammonia Engines: Specialized systems to address emissions and potential ammonia slip, including SCR and other techniques to convert pollutants into less harmful substances.

Ammonia-Hydrogen Dual Fuel Engines

Ammonia-Hydrogen Dual-Fuel Engine Design and Control: Optimize performance and emissions by efficiently combusting the ammonia-hydrogen mixture.

Ammonia-Diesel Dual-Fuel Engine Systems: Use a combination of ammonia and diesel fuel, with ammonia as the primary fuel and diesel for ignition and combustion control.

Ammonia Fuel Processing and Supply Systems: Techniques for cracking or reforming ammonia to produce hydrogen, and systems for storing, heating, and injecting ammonia into the engine.

Combustion Optimization for Ammonia-Fueled Engines: Control ignition, manage exhaust gas recirculation, and organize the combustion process to improve efficiency and reduce emissions.

Integrated Ammonia-Fueled Engine Systems: Unified design incorporating ammonia processing, fuel supply, combustion optimization, and emissions control for efficient and environmentally friendly operation.

Exhaust After treatment for Ammonia Engines

Ammonia Injection Systems for Exhaust Aftertreatment: Inject ammonia into the exhaust stream to facilitate NOx reduction, using multistage injection or controlled release systems.

Thermal Management of Exhaust After treatment Systems: Manage temperature to maintain optimal conditions for efficient reduction.

Integration of Ammonia Sources in Exhaust Aftertreatment Systems: Incorporate ammonia generators or ammonia-containing agents directly into the exhaust aftertreatment process.

Exhaust Aftertreatment System Configurations: Specific configurations for ammonia-fueled engines, involving catalytic converters, particulate filters, and other components to effectively treat exhaust emissions.

Key Patent Interpretation

Patent Highlights

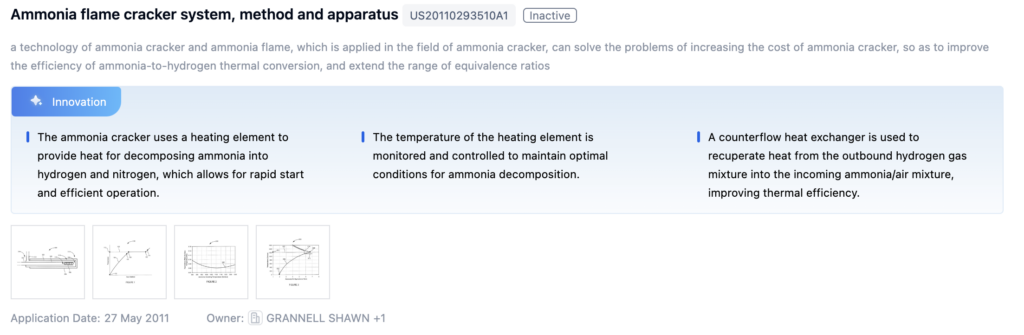

Patent 1: Ammonia Flame Cracker System Method and Apparatus

- Core Invention Points:

- Uses a heating element to decompose ammonia into hydrogen and nitrogen.

- Temperature control for optimal decomposition conditions.

- Counterflow heat exchanger to improve thermal efficiency.

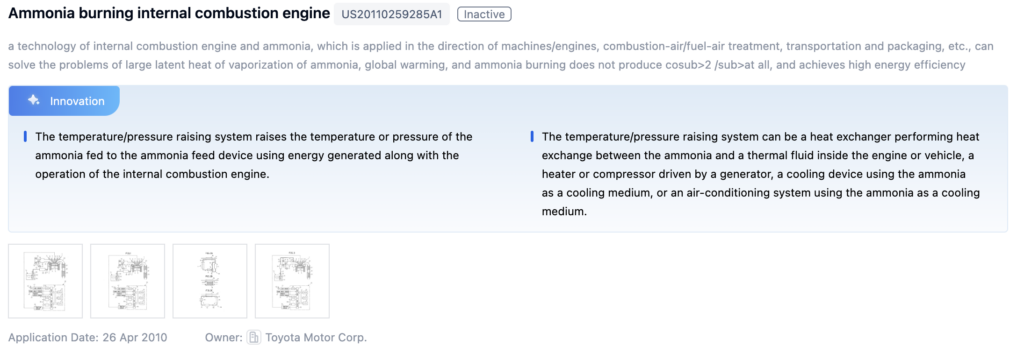

Patent 2: Ammonia Burning Internal Combustion Engine

- Core Invention Points:

- Uses a temperature/pressure raising system for ammonia feed.

- Heat exchanger for ammonia and thermal fluid inside the engine.

- Utilizes ammonia as a cooling medium for air-conditioning systems.

Patent 3: Apparatus System and Method for Operating an Oxygen-Enriched Ammonia-Fueled Spark Ignition Engine

- Core Invention Points:

- Uses oxygen as a combustion promoter, eliminating the need for gasoline.

- Simplifies the refueling process and fuel distribution by using ammonia as the sole fuel.

- Eliminates emissions such as unburned hydrocarbons, carbon monoxide, and carbon dioxide.

Possible Research Directions

- Ammonia Engine with High Thermal Efficiency through Ammonia Combustion Optimization: Techniques such as direct injection, thermal decomposition, and advanced combustion chamber designs to improve the combustion of ammonia and maximize energy extraction.

- Ammonia Engine with High Thermal Efficiency through Waste Heat Recovery: Systems and methods for recovering waste heat to improve overall thermal efficiency, using the recovered heat for preheating ammonia fuel, generating steam, or driving other energy recovery processes.

- Ammonia Engine with High Thermal Efficiency through Ammonia Cracking and Hydrogen Co-Combustion: Cracking ammonia into hydrogen and nitrogen, then co-combusting hydrogen with ammonia or other fuels to improve combustion efficiency and thermal efficiency.

- Ammonia Engine with High Thermal Efficiency through Advanced Fuel Injection and Air-Fuel Mixing: Techniques such as multi-point injection, Venturi-based mixing, and advanced injection strategies tailored for ammonia fuel to achieve better combustion and higher thermal efficiency.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!