Technical Background and Objectives

Background

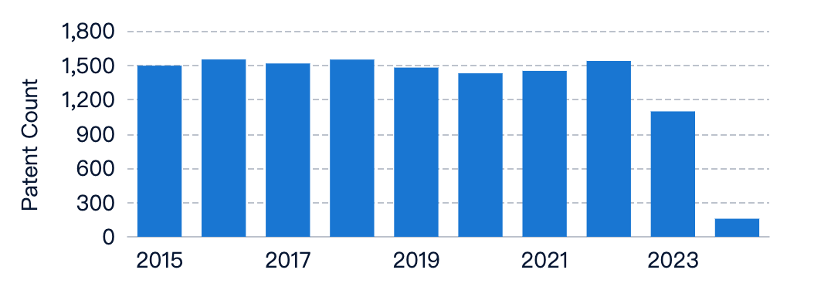

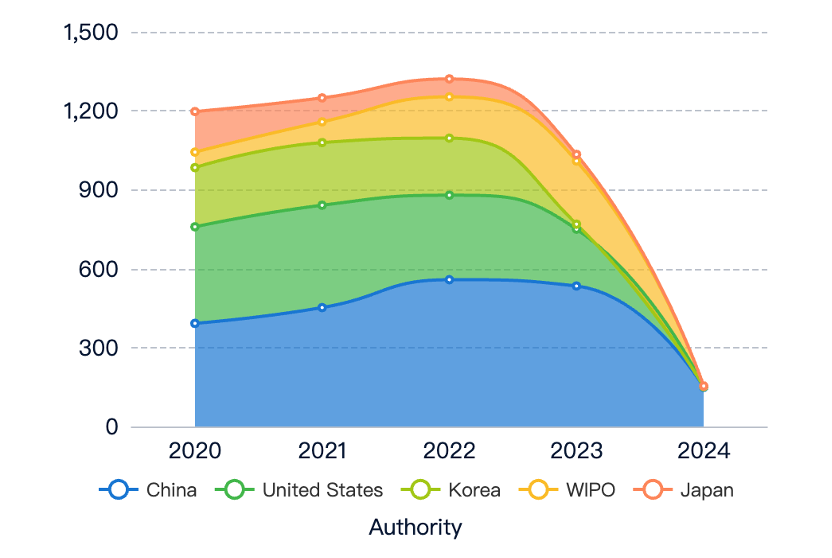

In the field of ammonia engine emission reduction, patent application data shows a relatively stable trend with fluctuations but no significant upward or downward trend. This suggests that research and development activities have maintained continuity without major breakthroughs. In contrast, the number of literature publications exhibits a pronounced upward trend in recent years, indicating increasing academic interest driven by environmental concerns and the need for cleaner energy solutions. This divergence suggests that while the industry has not experienced major breakthroughs in commercialization, the academic community is actively engaged in exploring new approaches to address emission reduction challenges associated with ammonia engines.

Objectives

The primary objective is to develop innovative solutions for reducing emissions from ammonia engines. This research aims to address challenges such as nitrogen oxides (NOx) and unburned ammonia slip by exploring advanced emission control strategies and technologies specifically tailored for ammonia engines.

To get a detailed scientific explanations of ammonia engine emission reduction, try Eureka.

Technical Current Status Analysis

Ammonia Engines

Ammonia is considered a promising alternative fuel for internal combustion engines due to its high hydrogen content, carbon-free combustion, and potential for reducing greenhouse gas emissions. However, the direct combustion of ammonia poses challenges, including low combustion efficiency, high NOx emissions, and potential engine system compatibility issues.

Applications and Impact:

- Transportation: Used in heavy-duty vehicles, marine vessels, and aviation to reduce environmental impact and meet emission regulations.

- Power Generation: Used in distributed or backup power systems, particularly in remote locations, to minimize local air pollution.

- Agricultural Sector: Powers farm machinery and equipment, reducing reliance on fossil fuels and minimizing environmental impact.

Technical Characteristics and Challenges:

- Combustion Characteristics: Narrow flammability range, high auto-ignition temperature, and low flame propagation speed can lead to incomplete combustion and increased unburned ammonia emissions.

- NOx Emissions: High combustion temperatures and the presence of nitrogen can result in harmful NOx emissions.

- Engine Compatibility: Ammonia’s corrosive nature and different combustion characteristics require modifications to engine designs and materials.

- Fuel Storage and Handling: Ammonia’s toxicity and corrosiveness necessitate specialized storage and handling systems.

- Fuel Supply and Infrastructure: Requires the development of a reliable ammonia production, distribution, and refueling infrastructure.

- Engine Efficiency and Performance: Achieving comparable efficiency and performance to traditional engines while meeting emission reduction targets.

Technological Paths:

- Advanced Combustion Strategies: Dual-fuel combustion, direct injection, or homogeneous charge compression ignition (HCCI) to improve efficiency and reduce emissions.

- Catalytic Aftertreatment Systems: Selective catalytic reduction (SCR) or lean NOx traps to reduce NOx emissions.

- Engine Design Optimization: Optimizing combustion chamber geometry, fuel injection systems, and exhaust gas recirculation (EGR) systems.

- Alternative Ammonia Production and Storage: Exploring electrolytic or renewable-based processes for ammonia production and advanced storage systems.

- Engine Materials and Coatings: Developing materials and coatings resistant to ammonia’s corrosive nature.

- Integrated System Approach: Considering the entire ammonia fuel cycle for maximum emission reduction and efficiency.

Research Content

Research Objectives

The primary objective is to develop innovative solutions for reducing emissions from ammonia engines, focusing on advanced combustion techniques, emission control strategies, and engine design optimizations.

Research Direction and Focus

Combustion Optimization and Fuel Injection Strategies

- Investigate advanced combustion modes like homogeneous charge compression ignition (HCCI) and reactivity-controlled compression ignition (RCCI).

- Use computational fluid dynamics (CFD) simulations and experimental studies to optimize air-fuel ratio, injection timing, and combustion chamber design.

Exhaust After treatment Systems

- Develop selective catalytic reduction (SCR) systems, ammonia slip catalysts (ASCs), and advanced catalytic converters.

- Optimize catalyst formulations, operating conditions, and system integration for performance and durability.

Engine Control and Monitoring Strategies

- Implement robust control algorithms adaptable to varying operating conditions and fuel compositions.

- Explore sensor technologies for real-time monitoring and feedback control.

- Employ machine learning and artificial intelligence to optimize engine performance and minimize emissions.

Technical Development Roadmap

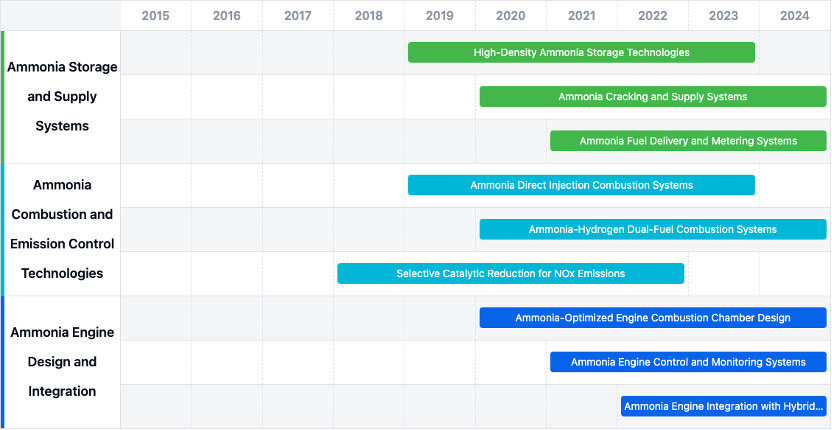

Key Areas of Advancement

- Ammonia Combustion and Emission Control Technologies: Development of ammonia direct injection systems, ammonia-hydrogen dual-fuel systems, and selective catalytic reduction for NOx control.

- Ammonia Storage and Supply Systems: Development of high-density ammonia storage technologies, ammonia cracking and supply systems, and ammonia fuel delivery systems.

- Ammonia Engine Design and Integration: Research on ammonia-optimized combustion chamber design, control and monitoring systems, and integration with hybrid systems.

Main Player Analysis

Key Players and Focus

- Oak Ridge National Laboratory: Research on passive selective catalytic reduction (SCR) systems, combustion modes for lean gasoline engines, and ammonia generation.

- Toyota Motor Corp.: Extensive patents on advanced catalytic converters, exhaust gas recirculation systems, and lean-burn engine technologies.

- The Ohio State University: Research on integrated power management and aftertreatment control for hybrid electric vehicles, observer-based estimation for SCR systems, and nonlinear model predictive control.

- GM Global Technology Operations LLC: Patents on advanced catalytic converters, exhaust gas recirculation systems, and lean-burn engine technologies.

- Robert Bosch GmbH: Patents in advanced catalytic converters, exhaust gas recirculation systems, and lean-burn engine technologies.

Current Technical Solution Overview

Ammonia Engine Emission Reduction Systems

Various systems and devices are designed to reduce emissions from ammonia engines, including aftertreatment systems, catalytic converters, and SCR systems that utilize ammonia or urea injection to reduce NOx emissions.

Ammonia-Based Emission Reduction Systems: Utilize ammonia or ammonia-based compounds to reduce emissions, particularly NOx, through injection into the exhaust stream.

Ammonia Generation and Supply Systems: Focus on generating and supplying ammonia onboard for SCR systems, using sources such as urea hydrolysis or ammonia storage tanks.

Combined Ammonia and Hydrogen Fuel Systems: Use ammonia and hydrogen mixtures for combustion, with emissions treated by aftertreatment systems.

Ammonia Emission Reduction for Livestock and Agricultural Facilities: Techniques such as air filtration, chemical treatment, or biological processes to capture and treat ammonia emissions.

Integrated Emission Control and Energy Optimization Systems: Combine emission reduction with energy optimization, incorporating catalytic converters, exhaust gas recirculation, and energy recovery systems.

Ammonia-Fueled Engines and Power Generation Systems

Ammonia is explored as an alternative fuel for engines and power generation, incorporating emission reduction techniques and efficient fuel systems.

Ammonia-Fueled Engines and Power Generation Systems: Systems using ammonia as a fuel, including internal combustion engines, gas turbines, and hybrid systems.

Emission Reduction Techniques for Ammonia Engines: Techniques such as SCR systems, lean NOx traps, and catalytic converters to reduce pollutants.

Ammonia-Hydrogen Dual Fuel Systems: Use ammonia and hydrogen to reduce emissions and improve efficiency.

Ammonia Fuel Supply and Storage Systems: Systems for storing, handling, and supplying ammonia, including liquefied ammonia storage and reforming systems.

Waste Heat Recovery and Energy Efficiency Improvements: Techniques for improving energy efficiency using waste heat recovery.

Ammonia Emission Reduction in Livestock and Agricultural Facilities

Techniques to reduce ammonia emissions from livestock and agricultural facilities, including air filtration, chemical treatment, and biological processes.

Ammonia Emission Reduction in Livestock and Poultry Facilities: Specialized housing designs, air filtration systems, and manure management techniques.

Ammonia Emission Reduction from Agricultural Soils: Specialized fertilizer formulations, application methods, or soil amendments.

Ammonia Emission Reduction in Ammonia-Based Engines: Catalytic converters, ammonia storage systems, or control strategies.

Ammonia Emission Reduction in Industrial Processes: Technologies for capturing and treating ammonia emissions in industrial processes.

Ammonia Production and Utilization for Emission Reduction

Methods for producing and utilizing ammonia for emission reduction in engines or industrial processes.

Ammonia Production for SCR Systems: Onboard ammonia generation for SCR systems using urea hydrolysis or ammonia cracking.

Ammonia Utilization in Internal Combustion Engines: Use of ammonia as a fuel or fuel additive in engines.

Ammonia Emission Reduction in Livestock and Poultry Farming: Systems for capturing, treating, and utilizing ammonia emissions from farming operations.

Ammonia Emission Control in Chemical Processes: Reducing ammonia emissions in chemical processes through recycling, treating tail gases, and optimizing conditions.

Key Patent Interpretation

Patent Highlights

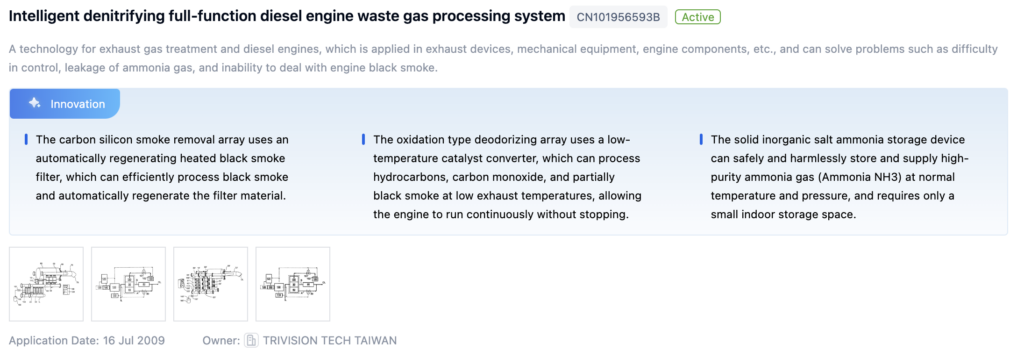

Patent 1: Intelligent Denitrifying Full-Function Diesel Engine Waste Gas Processing System

- Core Invention Points:

- Uses an automatically regenerating heated black smoke filter to efficiently process black smoke.

- Uses a low-temperature catalyst converter for hydrocarbons, carbon monoxide, and partially black smoke.

- Solid inorganic salt ammonia storage device safely stores and supplies high-purity ammonia at normal temperature and pressure.

Patent 2: Catalytic Reduction Urea Injection Control Method for Diesel Engine Based on Real-Time Ammonia Storage Management

- Core Invention Points:

- Establishes an ammonia storage calculation model to calculate current ammonia storage under actual conditions.

- Calibrates the target ammonia storage area and injection volume through experiments.

- Controls urea injection to maintain ammonia storage close to the target area.

Patent 3: A Method Based on the Use of Liquid Ammonia Technology to Promote Diesel Engines for Energy Saving and Emission Reduction

- Core Invention Points:

- Precise control of ammonia injection for catalytic conversion of nitrogen oxides with a conversion rate over 99.5%.

- Simple structure with high durability and low user cost.

Possible Research Directions

- Ammonia Engine Emission Reduction Systems: Develop systems to reduce emissions from ammonia-fueled engines, including aftertreatment systems, catalytic converters, and SCR systems.

- Ammonia Combustion and Emission Control Methods: Techniques to control combustion and emissions in ammonia engines, reducing NOx emissions and optimizing combustion parameters.

- Ammonia-Based Fuel Systems for Engines: Design fuel systems for using ammonia as a fuel, including pretreatment devices and fuel injection systems.

- Ammonia Emission Reduction in Livestock and Agricultural Facilities: Technologies to reduce ammonia emissions from livestock housing and agricultural facilities.

- Ammonia Production and Utilization for Emission Reduction: Methods for producing and utilizing ammonia for emission reduction in engines and industrial processes.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!