Bismaleimide (BMI) resins have become essential in advanced materials, especially in industries that require high strength, thermal stability, and electrical insulation. These resins offer unique benefits in various fields, including aerospace, automotive, and electronics. This article will explore the chemistry, applications, benefits, and future trends of BMI resins, highlighting why they have become a key material in modern engineering.

What is Bismaleimide?

Bismaleimide is a thermosetting resin made from maleimide and bismaleimide monomers. These resins undergo a curing process when heated, forming a hard and durable polymer. Their unique structure grants them excellent thermal stability, mechanical strength, and electrical insulation properties.

Key Characteristics:

- High thermal stability

- Exceptional mechanical strength

- Excellent electrical insulation

- Resistant to corrosion and high temperatures

The Chemistry of Bismaleimide Resins

Bismaleimide’s performance stems from its chemical properties. Manufacturers produce BMI resins by reacting bismaleimide monomers with curing agents or hardeners. The curing process forms a dense, cross-linked polymer network, providing the material with its strength and stability.

- Polymerization Process: During curing, maleimide groups react with other molecules to form a tightly bonded structure.

- Thermal Stability: This cross-linked structure helps Bismaleimide resist high temperatures, making it ideal for extreme heat conditions.

Advantages of Bismaleimide Resins

BMI resins offer several advantages over other thermosetting polymers, including:

- Thermal Resistance: BMI resins can withstand continuous service temperatures up to 250°C, making them ideal for high-heat applications.

- Mechanical Strength: The resins exhibit high load-bearing capacity and wear resistance.

- Chemical Resistance: BMI resins resist corrosion and harsh chemicals, which enhances the longevity of components made from them.

Want to explore the advantages of Bismaleimide resins? Eureka Technical Q&A provides in-depth analysis of their superior thermal stability, electrical properties, and resistance to chemicals, helping you make informed decisions about using these advanced materials in your engineering and manufacturing projects.

Applications of Bismaleimide Resins

BMI resins are used in various industries where performance under extreme conditions is crucial:

- Aerospace: Manufacturers use BMI resins in lightweight, high-strength composites for aircraft components like wings, fuselages, and engine parts. Their high thermal stability ensures components can endure the harsh conditions of flight.

- Automotive: In automotive manufacturing, BMI resins help create durable, lightweight parts, including brake components and engine covers.

- Electronics: BMI resins provide excellent electrical insulation, making them perfect for circuit boards, connectors, and insulators.

- Military and Defense: The durability and resilience of BMI resins make them a go-to material for military applications, where reliability in extreme conditions is essential.

Performance Comparison: Bismaleimide vs. Other High-Performance Polymers

| Feature | Bismaleimide | Epoxy Resins | Phenolic Resins |

|---|---|---|---|

| Thermal Stability | 250°C and above | 150°C to 180°C | 200°C to 250°C |

| Mechanical Strength | High | Moderate to High | Moderate |

| Electrical Insulation | Excellent | Good | Poor |

| Chemical Resistance | Excellent | Moderate | Excellent |

| Curing Time | Moderate | Short | Long |

BMI resins offer better thermal stability, strength, and electrical insulation than other common thermosetting polymers, making them suitable for applications in extreme environments.

Challenges and Limitations of Bismaleimide Resins

Despite their numerous benefits, BMI resins present some challenges:

- Cost: BMI resins can cost more than alternatives like epoxy resins, limiting their use in price-sensitive applications.

- Processing Complexity: The curing process requires precise temperature and time control, complicating manufacturing.

- Brittleness: Under certain conditions, BMI resins can become brittle, requiring reinforcement with fibers or other materials.

Future Trends in Bismaleimide Resin Technology

The future of BMI resins looks bright with advancements in material science:

- Advanced Manufacturing Techniques: Techniques like 3D printing allow for the creation of complex Bismaleimide components with high precision.

- Eco-friendly Bismaleimide: Researchers are developing sustainable, bio-based BMI resins to reduce the environmental impact of the material.

- Hybrid Composites: BMI resins combined with carbon fiber and other advanced materials will lead to even stronger, lighter composites for aerospace, automotive, and defense applications.

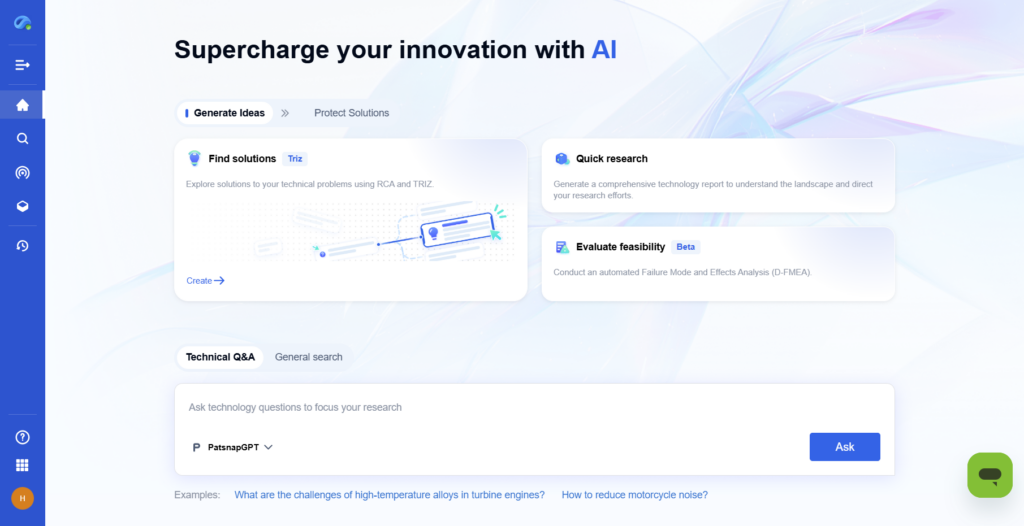

How Eureka by PatSnap Supports Bismaleimide Resin R&D

What is Eureka by PatSnap?

Eureka by PatSnap is an AI-powered research tool that helps accelerate innovation by providing access to the latest patents, competitive intelligence, and technology trends.

How Eureka Supports Bismaleimide Resin Development

- Patent Analysis: Researchers can track the latest innovations in BMI resin chemistry and applications.

- Competitive Intelligence: Manufacturers can benchmark against leading companies in aerospace, automotive, and electronics.

- Technology Roadmapping: Stay ahead of trends in material science and help companies develop the next generation of Bismaleimide-based products.

Conclusion

Bismaleimide resins provide exceptional thermal stability, mechanical strength, and electrical insulation, making them ideal for industries like aerospace, automotive, and electronics. While the material poses challenges in terms of cost and processing, its performance in extreme conditions justifies its use. As material science continues to advance, BMI resins will play an even more significant role in high-performance applications.

FAQs

1️⃣ What makes Bismaleimide resins better than epoxy?

BMI resins offer superior thermal stability, mechanical strength, and electrical insulation, making them perfect for extreme environments like aerospace.

2️⃣ Can Bismaleimide resins be used for 3D printing?

Yes, research is developing BMI resins suitable for 3D printing, enabling the production of precise, high-performance parts.

3️⃣ Are Bismaleimide resins environmentally friendly?

While traditionally synthetic, researchers are working on sustainable, bio-based Bismaleimide resins to reduce environmental impact.

4️⃣ How does Bismaleimide perform in high-temperature environments?

BMI resins can withstand continuous service temperatures up to 250°C, making them ideal for high-heat applications.

5️⃣ What industries use BMI resins?

BMI resins are commonly used in aerospace, automotive, electronics, and defense industries due to their high strength, thermal stability, and electrical insulation properties.

To get detailed scientific explanations of Bismaleimide, try Patsnap Eureka.