CNT Evolution and Objectives

Since their discovery in 1991, carbon nanotubes (CNTs) have reshaped the landscape of nanotechnology. These cylindrical carbon structures offer unmatched strength, conductivity, and heat resistance. Their unique properties have made them a key focus for both researchers and industries across the globe.

Whether you’re exploring the structure of carbon nanotubes or their applications in electronics and nanomedicine, Eureka Technical Q&A gives you direct access to expert insights—helping you understand advanced materials science concepts with clarity and practical depth.

Early CNT research focused on understanding their structure and behavior. Scientists worked to develop consistent methods for producing and analyzing these tiny but powerful materials. Over time, advancements in synthesis techniques and characterization tools accelerated progress.

As production methods improved, attention shifted to real-world applications. CNTs began showing promise in electronics, energy storage, aerospace, and biomedical fields. Today, research efforts continue to evolve. The focus now includes refining control over CNT structure and scaling up production for commercial use.

One major challenge remains: large-scale manufacturing. Producing CNTs in bulk while maintaining quality is still difficult. Researchers also face hurdles in purifying CNTs and integrating them into complex systems. Despite these obstacles, momentum continues to grow.

Looking ahead, several goals shape the future of CNT technology. First, scientists aim to develop more affordable and energy-efficient production methods. At the same time, they work to control CNT behavior at the atomic level. These improvements will unlock new possibilities in advanced materials and devices.

Another key area of development involves hybrid materials. By combining CNTs with other nanomaterials, researchers hope to create novel functionalities and improved performance. These combinations could lead to breakthroughs in energy efficiency, medical devices, and environmental solutions.

Sustainability is also becoming a major priority. As CNT use expands, concerns over environmental and health impacts must be addressed. Researchers are now developing safer production processes and studying the long-term effects of CNT exposure.

Ultimately, the goal is to make CNTs a seamless part of everyday technologies. From flexible electronics to next-generation batteries, CNTs could transform how we power, build, and heal. Their journey reflects the power of scientific progress—each breakthrough paving the way for even greater innovation.

CNT Market Demand Analysis

Carbon nanotubes (CNTs) have emerged as a revolutionary material with diverse applications across multiple industries, driving significant market demand. The global CNT market is experiencing robust growth, with projections indicating a compound annual growth rate (CAGR) of 14.5% from 2021 to 2026, reaching an estimated value of $5.8 billion by the end of this period. This growth is primarily fueled by the increasing adoption of CNTs in various sectors, including electronics, aerospace, automotive, and energy storage.

In the electronics industry, CNTs are gaining traction due to their exceptional electrical and thermal properties. The demand for miniaturization and improved performance in electronic devices is driving the incorporation of CNTs in transistors, sensors, and conductive coatings. The automotive sector is another key driver of CNT market growth, with applications in lightweight composites for vehicle bodies and components, as well as in battery technologies for electric vehicles.

The aerospace industry is also contributing significantly to the CNT market demand, utilizing these materials in structural composites to reduce weight and enhance fuel efficiency. Additionally, the energy storage sector is witnessing increased adoption of CNTs in lithium-ion batteries and supercapacitors, driven by the growing demand for renewable energy solutions and electric vehicles.

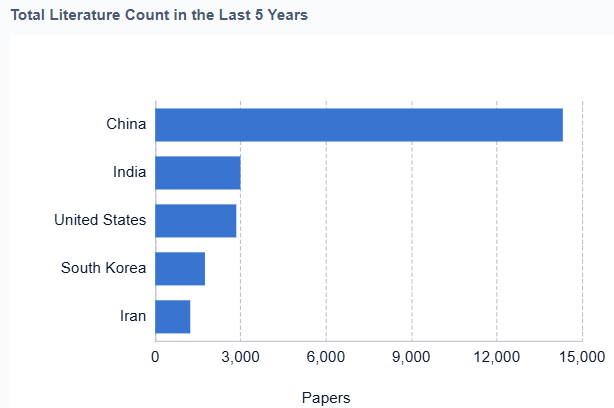

Regionally, Asia-Pacific is expected to dominate the CNT market, with China and Japan leading in production and consumption. North America and Europe are also significant markets, particularly in high-tech applications and research and development activities.

Despite the positive growth trajectory, challenges such as high production costs and concerns about potential health and environmental impacts of CNTs persist. However, ongoing research and development efforts are focused on addressing these issues, which is expected to further boost market demand in the coming years.

The CNT market is also witnessing a shift towards more specialized and high-performance applications. This trend is driven by advancements in CNT synthesis and purification techniques, enabling the production of CNTs with tailored properties for specific applications. As a result, industries are increasingly exploring the potential of CNTs in cutting-edge technologies such as flexible electronics, advanced composites, and next-generation energy storage solutions.

In conclusion, the market demand for carbon nanotubes is poised for substantial growth, driven by their unique properties and diverse applications across multiple industries. As research continues to unlock new possibilities and overcome existing challenges, the CNT market is expected to expand further, offering significant opportunities for innovation and technological advancement in various sectors.

CNT Development Status

Carbon nanotubes (CNTs) have emerged as a revolutionary material with exceptional properties, attracting significant attention from researchers and industries worldwide. The current development status of CNTs reflects a dynamic landscape of scientific advancements and industrial applications. In recent years, substantial progress has been made in the synthesis, characterization, and application of CNTs across various sectors.

The production of CNTs has seen remarkable improvements, with enhanced control over their structure, purity, and scalability. Advanced synthesis methods, such as chemical vapor deposition (CVD) and arc discharge techniques, have been refined to produce high-quality CNTs with specific characteristics. This has led to increased availability of both single-walled and multi-walled CNTs, catering to diverse industrial needs.

In terms of research and development, CNTs continue to be at the forefront of materials science. Numerous studies have focused on understanding and manipulating their unique electronic, mechanical, and thermal properties. This has resulted in the development of novel CNT-based composites, sensors, and electronic devices with superior performance characteristics.

The industrial adoption of CNTs has gained momentum, particularly in sectors such as electronics, aerospace, and energy storage. CNT-enhanced composites are being increasingly used in lightweight, high-strength materials for aerospace applications. In the electronics industry, CNTs are finding applications in flexible displays, transparent conductive films, and next-generation transistors.

However, challenges persist in the large-scale commercialization of CNT-based products. Issues related to cost-effective mass production, consistent quality control, and integration into existing manufacturing processes remain areas of active research and development. Efforts are ongoing to address these challenges through improved synthesis techniques and innovative manufacturing approaches.

Environmental and health concerns associated with CNTs have also gained attention, leading to increased research on their potential impacts and the development of safety guidelines for handling and disposal. This has resulted in a more comprehensive understanding of CNT toxicology and the implementation of responsible manufacturing practices.

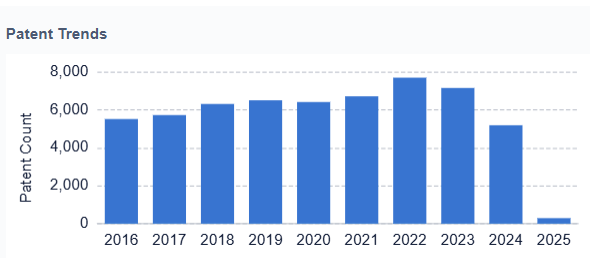

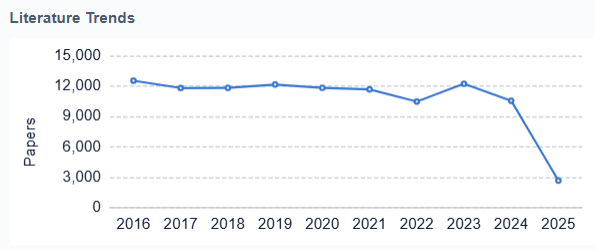

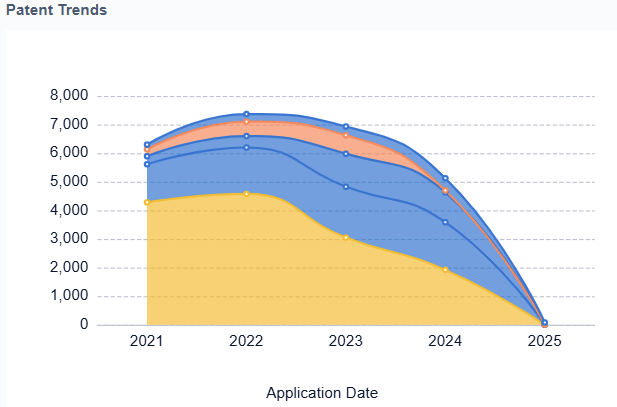

Globally, research institutions and companies in North America, Europe, and Asia are at the forefront of CNT development. Collaborations between academia and industry have accelerated the translation of laboratory discoveries into practical applications. Patent activities in the CNT field have shown a steady increase, indicating a growing interest in protecting intellectual property related to CNT technologies.

In summary, the current development status of CNTs is characterized by significant scientific progress, expanding industrial applications, and ongoing efforts to overcome commercialization challenges. As research continues to unlock new potentials of CNTs, their impact on various technological domains is expected to grow, paving the way for innovative solutions in materials science and engineering.

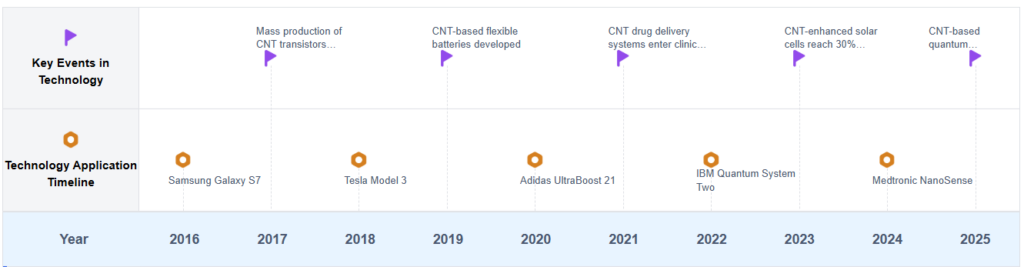

CNT Technology Roadmap

Key CNT Industry Players

The carbon nanotubes market is in a growth phase, characterized by increasing applications across industries and ongoing research and development. The global market size is projected to expand significantly, driven by demand in electronics, aerospace, and energy sectors. Technologically, carbon nanotubes are advancing rapidly, with companies like Nantero, Inc. and Hyperion Catalysis International leading in commercialization efforts. Academic institutions such as Tsinghua University and Rensselaer Polytechnic Institute are pushing the boundaries of fundamental research. Major corporations like IBM and Intel are exploring CNT applications in next-generation electronics. The technology’s maturity varies across applications, with some areas nearing commercial readiness while others remain in early development stages, indicating a dynamic and competitive landscape.

Nantero, Inc.

Nantero, Inc.

Technical Solution

Nantero has developed NRAM (Nanotube-Based/Non-Volatile Random Access Memory) using carbon nanotubes. Their technology creates a fabric of carbon nanotubes deposited on a standard silicon substrate. The nanotubes can be placed in two stable states, representing 0 and 1, allowing for non-volatile memory storage. Nantero’s NRAM promises faster write speeds, lower power consumption, and higher endurance compared to traditional memory technologies. They are working on commercializing this technology for various applications, including consumer electronics, enterprise systems, and automotive electronics.

Strengths: Non-volatile memory with high speed and low power consumption.

Weaknesses: Manufacturing challenges at scale, competition from established memory technologies.

LG Chem Ltd.

LG Chem Ltd.

Technical Solution

LG Chem has been developing carbon nanotube-based materials for various applications. Their focus includes the production of high-quality carbon nanotubes for use in battery electrodes, conductive plastics, and structural composites. LG Chem’s approach involves optimizing the synthesis process to produce nanotubes with specific properties tailored for different applications. They have also developed methods to incorporate carbon nanotubes into polymer matrices, enhancing the mechanical and electrical properties of composite materials used in automotive and electronics industries.

Strengths: Diverse applications in energy storage and advanced materials.

Weaknesses: Competition in the carbon nanomaterials market, potential environmental concerns.

International Business Machines Corp.

International Business Machines Corp.

Technical Solution

IBM has developed a process for separating semiconducting carbon nanotubes from metallic ones, which is crucial for creating high-performance transistors. Their method involves using polymer wrapping and column chromatography to achieve a purity of 99.9% semiconducting nanotubes. This breakthrough allows for the creation of carbon nanotube transistors that can potentially replace silicon in future computer chips, offering higher performance and energy efficiency.

Strengths: High purity separation technique, potential for superior transistor performance.

Weaknesses: Scalability challenges, integration with existing semiconductor manufacturing processes.

Tekna Plasma Systems, Inc.

Technical Solution

Tekna specializes in plasma-based processes for nanomaterial production, including carbon nanotubes. Their technology uses induction plasma to synthesize high-quality, single-walled carbon nanotubes (SWCNTs) at industrial scales. Tekna’s process allows for precise control over nanotube properties, such as diameter and chirality, which are crucial for specific applications. They focus on producing nanotubes for advanced composites, energy storage devices, and electronics. Tekna’s plasma technology offers advantages in terms of scalability and purity compared to traditional chemical vapor deposition methods.

Strengths: Scalable production of high-quality nanotubes, precise control over nanotube properties. Weaknesses: High energy consumption of plasma processes, competition from established production methods.

Intel Corp.

Intel Corp.

Technical Solution

Intel has been researching carbon nanotubes as a potential replacement for silicon in transistors. They have developed a technique called “ring oscillator” to create functioning circuits using carbon nanotubes. This involves depositing nanotubes onto a silicon wafer and using them to build transistors. Intel’s approach focuses on overcoming the challenges of precise nanotube placement and reducing metallic impurities to create reliable, high-performance transistors that could potentially extend Moore’s Law beyond the limitations of silicon.

Strengths: Integration with existing semiconductor manufacturing infrastructure, potential for high-performance computing.

Weaknesses: Challenges in precise nanotube placement and purity control.

Current CNT Applications

Synthesis and production methods of carbon nanotubes

- Various methods for synthesizing and producing carbon nanotubes, including chemical vapor deposition, arc discharge, and laser ablation techniques. These processes involve controlling growth conditions, catalysts, and precursor materials to achieve desired nanotube structures and properties.

- Chemical vapor deposition (CVD) methods

Chemical vapor deposition is a widely used method for synthesizing carbon nanotubes. This process involves the decomposition of carbon-containing gases at high temperatures in the presence of metal catalysts. The carbon atoms then arrange themselves into tubular structures, forming nanotubes. Various parameters such as temperature, pressure, and catalyst composition can be adjusted to control the properties of the resulting nanotubes. - Arc discharge synthesis

Arc discharge is another common method for producing carbon nanotubes. This technique involves creating an electric arc between two graphite electrodes in an inert gas atmosphere. The high temperature generated by the arc vaporizes the carbon, which then condenses to form nanotubes. The process can be modified by using different catalysts or adjusting the gas composition to control the type and quality of nanotubes produced. - Laser ablation technique

Laser ablation is a method that uses intense laser pulses to vaporize a graphite target containing small amounts of metal catalysts. The vaporized carbon condenses to form nanotubes as it cools. This technique allows for good control over the diameter of the nanotubes produced and can yield high-quality single-walled carbon nanotubes. The process typically occurs in a high-temperature reactor filled with inert gas. - Plasma-enhanced synthesis

Plasma-enhanced methods utilize plasma to create carbon nanotubes. This approach can lower the overall process temperature compared to thermal CVD methods. The plasma provides energy to break down the carbon-containing precursor gases and can enhance the growth rate of nanotubes. Various types of plasma sources, such as microwave or radio frequency, can be used in this synthesis method.

Functionalization and modification of carbon nanotubes

Techniques for modifying carbon nanotubes to enhance their properties or compatibility with other materials. This includes chemical functionalization, surface treatments, and incorporation of additional elements or compounds to tailor the nanotubes for specific applications.Expand

Carbon nanotube-based composites and materials

Development of composite materials incorporating carbon nanotubes to enhance mechanical, electrical, or thermal properties. This includes polymer composites, metal matrix composites, and hybrid materials combining nanotubes with other nanomaterials or conventional materials.Expand

Applications of carbon nanotubes in electronics and energy

Utilization of carbon nanotubes in electronic devices, energy storage, and conversion systems. This includes applications in transistors, sensors, supercapacitors, batteries, and solar cells, leveraging the unique electrical and thermal properties of nanotubes.Expand

Characterization and quality control of carbon nanotubes

Methods and techniques for analyzing and assessing the quality, purity, and properties of carbon nanotubes. This includes spectroscopic techniques, microscopy, and other analytical methods to determine nanotube structure, dimensions, and composition.

CNT Research Breakthroughs

Future CNT Innovations

Advanced CNT-Based Composites: Shaping the Future of Materials Science

Advanced CNT-based composites are redefining material performance across multiple industries. By blending carbon nanotubes (CNTs) with polymers, metals, or ceramics, scientists are creating materials with exceptional strength, conductivity, and heat resistance.

This exciting area of innovation focuses on enhancing material capabilities through strategic CNT integration. Here are the key areas driving development:

1. Dispersion and Functionalization

Uniformly dispersing CNTs within a matrix remains essential. Researchers are refining functionalization techniques to improve compatibility. Better bonding between CNTs and the matrix leads to stronger and more reliable composites.

2. Scalable Manufacturing

Scaling production is a major challenge. Engineers are working on new mixing systems, advanced extrusion techniques, and even 3D printing. These innovations aim to make CNT-based composites viable for large-scale commercial use.

3. Tailored Property Design

Scientists can now tailor composite properties by adjusting CNT orientation, type, and concentration. This allows them to create materials optimized for specific tasks—whether it’s added strength, better conductivity, or improved heat control.

4. Multifunctional Capabilities

Developers are designing composites that serve multiple functions at once. Some materials now offer both high mechanical strength and excellent thermal or electrical performance. This flexibility is unlocking new design possibilities.

5. Self-Healing and Smart Materials

CNTs also enable the creation of smart and self-healing materials. These next-gen composites can sense changes, respond to stress, or repair themselves—perfect for high-performance, high-risk applications.

Real-World Applications

CNT-based composites are already making waves in several industries:

- Aerospace and Automotive: Lightweight yet strong materials for fuel-efficient, high-performance vehicles.

- Electronics: Flexible conductors for wearables and foldable devices.

- Energy Storage: Enhanced components for batteries, supercapacitors, and fuel cells.

- Construction: Stronger, more durable building materials with better insulation.

- Sports Equipment: Advanced gear with exceptional strength-to-weight ratios.

Strengths

- Offers superior mechanical, thermal, and electrical performance.

- Enables multifunctional design in a single component.

- Reduces weight while increasing efficiency and durability across industries.

Weaknesses

- High production costs due to complex synthesis and processing methods.

- Difficulty in achieving even CNT dispersion at industrial scales.

- Health and environmental concerns about CNT exposure and end-of-life handling.

The Road Ahead

Moving forward, success depends on collaboration. Materials scientists, engineers, and chemists must work together to refine manufacturing, improve safety, and push CNT composites into everyday products. With continued innovation, these advanced materials could revolutionize how we build, power, and connect our world.

CNT Environmental Impact

As carbon nanotubes (CNTs) gain popularity across industries, their environmental impact has become a growing concern. These nanoscale materials offer impressive benefits but also pose potential risks to ecosystems and human health.

Potential Environmental Release

During production, use, and disposal, CNTs can escape into the environment. These tiny particles may contaminate air, water, and soil. Because of their size, CNTs can interact with living systems in unpredictable ways.

In water systems, CNTs can build up and affect aquatic life. Some studies suggest they may enter the food chain. On land, they could influence soil microbes and plant health. However, researchers still need more data on long-term effects.

Persistence in the Environment

Unlike organic materials, CNTs resist natural degradation. This durability makes them valuable in applications—but it also means they can persist in the environment. Their long lifespan raises concerns about accumulation and potential classification as persistent organic pollutants (POPs).

Health Risks During Handling

Workers handling CNTs face another risk. Inhaling CNT particles may lead to lung issues. Some animal studies suggest a link to cancer, though more research is needed. These findings stress the importance of safety in manufacturing and lab settings.

Environmental Benefits of CNTs

Despite the risks, CNTs also offer environmental advantages. Their high surface area allows them to trap pollutants effectively. Engineers use them in water purification, air filtration, and chemical adsorption. These applications help remove contaminants from the environment.

Life Cycle and Sustainability Concerns

To fully understand their impact, researchers must assess the entire life cycle of CNTs. This includes energy use, emissions, and waste during production. End-of-life disposal also plays a key role. Without proper management, discarded CNTs may pose long-term threats.

Sustainable production methods are essential moving forward. Innovations should aim to reduce waste, cut emissions, and improve recyclability. Industries must also adopt safe handling and disposal practices to limit environmental release.

The Role of Regulation

Regulatory agencies are working to create guidelines for CNT safety. These standards focus on production, workplace exposure, and responsible disposal. As CNT use grows, ongoing research and updated regulations will be critical.

Balancing Innovation and Responsibility

CNTs offer transformative potential—but with that comes responsibility. Balancing innovation with safety ensures we protect both human health and the environment. As the science evolves, so must our policies and practices.

CNT Commercialization: Progress, Challenges, and Future Outlook

The commercialization of carbon nanotubes (CNTs) has evolved significantly over the past two decades. While early development faced major barriers, the landscape is rapidly changing thanks to technological advances and growing market demand.

Overcoming Early Challenges

At first, high production costs and limited scalability made CNTs impractical for most industries. Manufacturing methods were complex, inefficient, and expensive. However, breakthroughs in chemical vapor deposition (CVD) techniques have changed that. These advancements have improved production efficiency and lowered costs, making large-scale CNT synthesis more feasible than ever.

Rising Market Demand

As costs decline, CNT applications are expanding across key sectors. Electronics, aerospace, and energy storage now lead in CNT adoption. Companies use CNTs for their unmatched strength, electrical conductivity, and thermal performance. In electronics, CNTs enhance semiconductors, battery electrodes, and flexible displays. In aerospace, manufacturers use CNT-reinforced composites to build lightweight, high-strength parts for aircraft and spacecraft.

Remaining Commercial Barriers

Despite this progress, CNT commercialization still faces hurdles. One major challenge is maintaining quality and consistency at industrial scales. Manufacturers must ensure uniform properties across large batches to meet performance and safety standards. Additionally, regulatory agencies are closely monitoring CNT use due to potential health and environmental concerns. This has led to stricter compliance requirements and calls for improved safety protocols.

Future Growth Opportunities

Looking forward, CNTs show strong potential for next-generation applications. Researchers are exploring their use in water purification systems, advanced sensors, and energy storage solutions. The automotive sector is also joining in, using CNTs to create lighter materials and more efficient batteries for electric vehicles.

Mainstream Integration Ahead

As manufacturing methods improve, CNTs will likely become part of everyday consumer products. Lower costs and increased availability will support their integration into more applications. At the same time, regulatory bodies will establish clearer guidelines to ensure safe use across industries.

Key Drivers of Success

The continued growth of CNT commercialization depends on three main factors:

- Innovation in manufacturing to reduce costs and improve scalability

- Development of new applications in emerging sectors

- Addressing safety and sustainability to meet regulatory expectations

With these priorities in focus, CNTs are well-positioned to become a foundational material in the future of advanced technology and sustainable industry.

To get detailed scientific explanations of Carbon Nanotubes, try Patsnap Eureka.