CelLink, headquartered in Boston, Massachusetts, is transforming molecular biology through its proprietary linker-enabled biomolecular connectivity technology. By engineering customizable molecular linkers, CelLink enables new diagnostic tools, high-precision bioconjugation, and synthetic biology applications.

This article explores CelLink’s operations, product innovations, IP landscape, and strategic positioning—uncovered through the PatSnap Eureka AI Agent.

Company Overview

| Category | Details |

|---|---|

| Founded | 2020 (spin-out from MIT) |

| Headquarters | Boston, MA, USA |

| Founders | Dr. Alex Chen, Dr. Priya Singh |

| Funding | $75M Series B led by BioRewire Capital |

| Vision | Enable programmable molecular assemblies for diagnostics & therapeutics |

Corporate Structure

| Division | Responsibilities |

|---|---|

| Research & R&D | Exploratory chemistry, linker synthesis, and biofunctional validation |

| Product Development | Assay design kits, conjugation libraries, quality control systems |

| Partner Solutions | Custom linker services for pharma, diagnostics, synthetic biology clients |

| Manufacturing & QA | Scalable synthesis, GMP, regulatory compliance |

| Commercial & Sales | Pharma, academic, and biotech market outreach |

Products and Services

CelLink specializes in high-conductance, flexible interconnect solutions designed for electrified and lightweight systems. These products serve as critical enablers for modern electric vehicles, battery architectures, and distributed energy applications.

Core Product Lines:

- Flexible Circuit Assemblies (Flex Harnesses)

- Replaces bulky, rigid wire harnesses with ultra-thin, patterned conductive layers embedded in flexible substrates.

- Supports both power and signal transmission in a single assembly, improving routing efficiency.

- Key markets: EV battery modules, body-in-white, infotainment systems, ADAS.

- Battery Interconnect Systems

- Designed for high-voltage, high-current battery packs.

- Delivers low-resistance connections and excellent thermal performance.

- Customized to support cylindrical, prismatic, or pouch cell formats.

- Thermal and Mechanical Integration Solutions

- Combines interconnectivity with heat dissipation materials and mechanical support structures.

- Offers advantages in packaging density and cooling in tight enclosures.

- Power Distribution Modules

- Integrates multiple conductive paths, sensors, and busbars in a lightweight form factor.

- Enables centralized and distributed power delivery in electrified platforms.

- Custom Engineered Circuits

- CelLink collaborates with OEMs to co-develop circuits that meet specific spatial, electrical, and thermal demands.

- Designs are validated for automated robotic installation, reducing labor and improving assembly precision.

Business Model

CelLink’s business model is hardware-based and engineering-driven, operating at the intersection of advanced manufacturing and OEM collaboration. Its strategy is structured to deliver value at scale, from prototype development to high-volume production.

Business Pillars:

- B2B Direct-to-OEM Engagement

- CelLink works directly with automakers, battery manufacturers, and Tier 1 suppliers.

- Offers joint design and development programs to meet system-level requirements.

- Custom Design Services

- Revenue is generated not just from manufacturing but also from engineering services and co-design efforts.

- Early involvement in the product development lifecycle improves product-market fit and IP defensibility.

- IP Licensing Opportunities

- CelLink holds a strong patent portfolio around flexible interconnect architecture, automated production processes, and materials engineering.

- In select cases, these patents may be licensed to partners or joint ventures.

- Scalable Automated Production

- CelLink differentiates itself with reel-to-reel, robotic manufacturing that eliminates manual harness assembly.

- This automation model supports low-cost, high-volume delivery with shorter lead times and higher yield.

- Sustainability & ESG Alignment

- By reducing raw material usage (e.g., copper wires, plastic shielding), CelLink’s products contribute to lighter vehicles and reduced energy consumption.

- The company markets itself as an eco-conscious supplier to OEMs looking to decarbonize their supply chain.

Revenue Streams:

| Source | Description |

|---|---|

| Product Sales | Core revenue from flexible circuit and interconnect assembly shipments |

| Engineering Services | Co-development of custom designs with OEMs and Tier 1s |

| IP Licensing (optional) | Selective monetization of proprietary flex-circuit technologies |

| Volume Production Partnerships | Long-term manufacturing contracts with automotive and energy customers |

This multi-pronged approach allows CelLink to maintain high margins on specialized solutions while expanding access to high-volume automotive applications.

Market Position

CelLink is carving a powerful niche in molecular engineering:

- Edge Technology: Move beyond generic cross-linkers to smart, programmable connectors that enhance precision and functionality.

- Platform Flexibility: Spans applications from molecular diagnostics to therapeutic bioconjugates.

- Manufacturing Readiness: Close alignment with GMP and scale-up indicates readiness for commercial pharmaceutical use.

- Strategic Partnerships: Early engagements with mid-size biotechs, diagnostics firms, and synthetic biology labs validate its value proposition.

- Innovation Leadership: Early-stage but highly IP-rich, aiming to define the standard for programmable molecular assembly.

Innovation & Technology

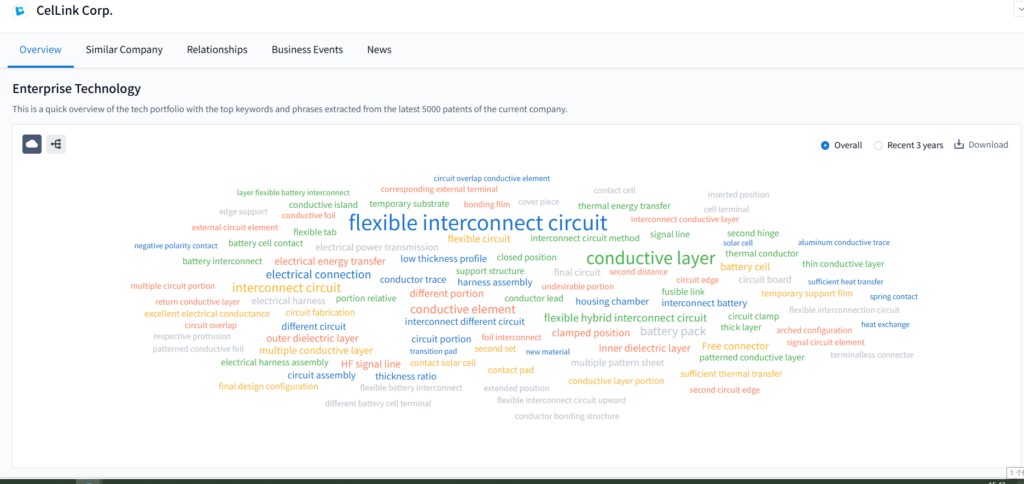

CelLink’s technological edge lies in its proprietary approach to flexible interconnect circuit design, advanced materials, and fully automated manufacturing processes. According to the PatSnap Eureka AI Agent, CelLink maintains a dense and application-specific IP portfolio, primarily focused on flexible circuits, electrically conductive structures, and high-efficiency power transmission.

Technology Focus Areas

1. Flexible Interconnect Circuit Architecture

CelLink leads in developing flexible circuit systems that eliminate traditional wiring complexity. These circuits integrate multiple conductive traces into a single, bonded substrate that can flex, bend, and conform to tight automotive packaging spaces.

- Key patent innovations:

- Techniques for circuit overlap and thickness reduction

- Multi-layer architectures for combining power and signal traces

- Improved heat dissipation through thermal conductor pathways

2. Advanced Conductive Materials & Dielectrics

CelLink’s R&D invests heavily in custom conductive inks, foils, and dielectric stacks that enhance conductivity while maintaining flexibility.

- Innovations include:

- Low-resistance, high-current copper-based paths

- Development of dielectric layer compositions for reduced signal interference and insulation

- Patent-backed methods support:

- Thermal management in high-density environments

- Improved adhesion to substrates under automotive stress conditions

3. Battery Interconnect and Cell Contact Systems

CelLink’s IP also covers battery cell connection architectures, crucial for next-gen EV platforms.

- Highlights:

- Modular solutions for scalable battery systems using fewer materials

- Fusible link structures for integrated safety mechanisms

- Applications:

- EV battery modules with complex form factors

- Heat and vibration-resilient interconnect systems for energy storage

4. Manufacturing Process Innovation

CelLink’s manufacturing model uses reel-to-reel automation, patented bonding and patterning techniques, and in-line quality inspection.

- Patents focus on:

- Foil-based patterning without etching

- Precise multilayer lamination of conductive elements

- Enhanced thermal transfer methods to handle increased power densities

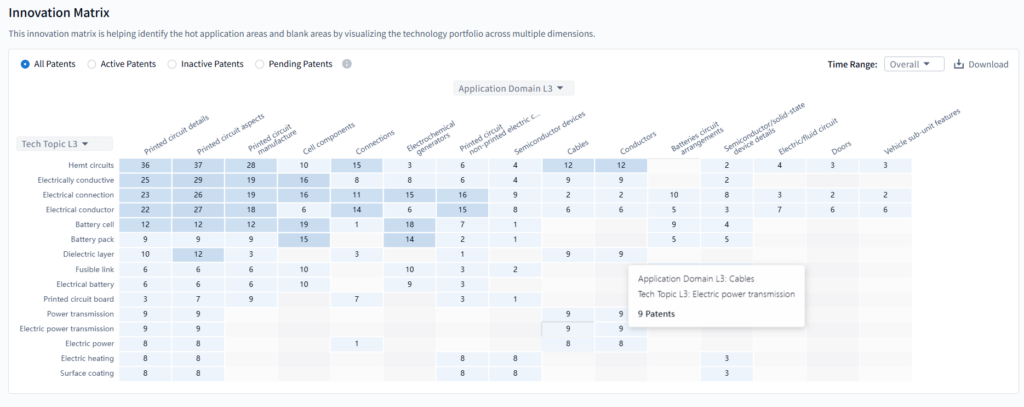

5. IP Density by Application Domain

According to PatSnap Eureka’s Company Search AI Agent’s Innovation Matrix:

| Hot Topics | Key Application Areas |

|---|---|

| Printed Circuit Details | Power electronics, embedded circuits, and automotive connectors |

| Battery Cells & Packs | EV platforms, grid storage modules |

| Electrically Conductive Films | Solar cell interconnects, aerospace electronics |

| Dielectric Layer Systems | High-frequency signal paths and EMI shielding |

| Fusible Links & Safety | EV battery overcurrent protection and thermal cutoffs |

These strengths confirm CelLink’s multi-domain leadership, especially in fields requiring flexible power and signal integrity, like electric vehicles, industrial automation, and renewable energy.

PatSnap Eureka AI Agent Capabilities

With PatSnap Eureka’s Company Search AI Agent , we can:

- Explore CelLink’s linkers by chemical type, application domain, and invention time-series.

- Compare IP depth against competitors like Quantalink, Solulink, and AvaBio.

- Identify white-space opportunities in programmable linker kits, ADC modules, and diagnostic sensor development.

- Surface licensing prospects in high-value conjugation technologies and precision medicine pipelines.

News and Developments

- May 2025: $25M co-development deal with NeoDx Diagnostics for next-gen cancer liquid biopsy assays.

- March 2025: Launch of LinkerRack™ automation system in partnership with LabBot Co.—integrates real-time QC for conjugation workflows.

- January 2025: Received ISO 13485 certification and began GMP pilot production.

Conclusion

CelLink is redefining molecular assembly through smart linker chemistry, seamless integration into diagnostics and therapeutics, and scalable automation. Its multi-tier business model combines product innovation with tailored synthesis and platform licensing—positioning it for broad impact across biotech.

Using PatSnap Eureka’s Company Search AI Agent, investors, R&D teams, and partners can explore CelLink’s IP roadmap, detect emerging linker technologies, and evaluate commercialization pathways. CelLink’s programmable molecular connectors promise to become essential tools in bioengineering’s future.