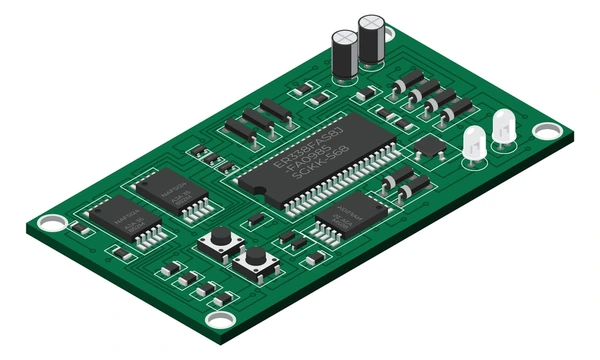

Introduction to Circuit Board Components

A printed circuit board (PCB) is the backbone of modern electronic devices, providing a platform for mounting and connecting electronic components. PCBs enable efficient signal transmission and power distribution, forming the foundation for everything from smartphones and laptops to industrial machinery and medical equipment. In this article, we’ll explore the importance of PCBs, their structure, and their role in driving advancements in electronic technology.

Passive Components: Resistors, Capacitors, and Inductors

Resistors: Regulating Current Flow

Resistors are designed to limit or control the flow of electric current in a circuit. They serve various purposes, such as current limiting, voltage division, and load balancing. Resistors are made from materials like carbon, metal films, or wire-wound constructions, each offering unique characteristics suited for specific applications.

Capacitors: Storing Electrical Energy

Capacitors store energy in an electrostatic field between two conductive plates separated by an insulating material called a dielectric. They are widely used in filtering, bypassing, coupling, and energy storage applications. Different types, such as ceramic, electrolytic, and film capacitors, are available to meet the diverse needs of electronic systems.

Inductors: Harnessing Magnetic Fields

Inductors store energy in the form of a magnetic field, typically created by winding a coil of wire around a core material like air or ferrite. These components are critical in radio frequency (RF) circuits, filters, and power supply systems. Inductors are also commonly paired with capacitors to form resonant circuits and filters.

Integration and Miniaturization

As devices become smaller and more powerful, passive components are increasingly integrated into integrated circuits (ICs) and printed circuit boards (PCBs). Techniques like embedding components within substrate layers or printing them directly onto the substrate are making it possible to achieve greater miniaturization and performance.

Applications and Challenges

Passive components are used in everything from consumer electronics to industrial and automotive systems. However, their performance can be affected by factors like frequency, temperature, and aging. To address these challenges, ongoing research focuses on improving reliability, enhancing performance, and advancing integration methods to meet the growing demands of modern electronics.

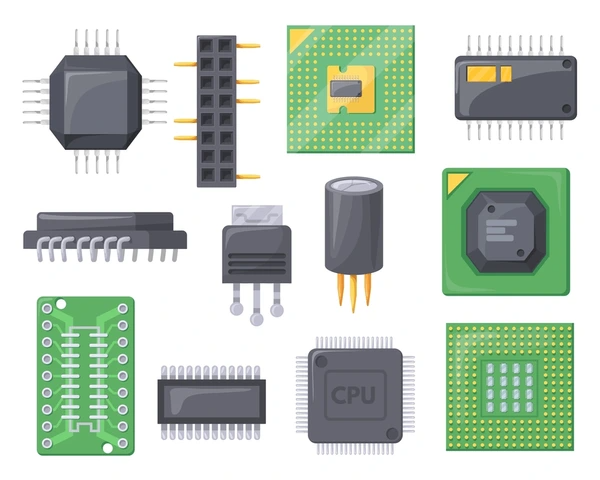

Active Components: Diodes, Transistors, and ICs

Diodes: Directing Current Flow

Diodes are semiconductor devices that allow current to flow in one direction while blocking it in the opposite direction. Their asymmetric current-voltage characteristic makes them ideal for rectifying alternating currents. While diodes cannot amplify or oscillate, they effectively control electron flow. Common examples include:

- Conventional Diodes: Used in rectifiers and clamping circuits.

- Light-Emitting Diodes (LEDs): Emit light when current flows through them, widely used in displays and lighting.

- Photodiodes: Detect light and convert it into electrical signals, ideal for sensors and optical communication.

Transistors: Amplification and Switching

Transistors are active components capable of amplifying signals, controlling currents, and enabling oscillation. These components are the foundation of modern electronics, essential in integrated circuits and standalone applications. By applying a small signal to a control terminal, transistors regulate electron flow, acting as either switches or amplifiers.

Integrated Circuits (ICs): Miniaturized Powerhouses

Integrated circuits combine numerous active and passive components, such as transistors, resistors, and capacitors, on a single semiconductor substrate. ICs are designed for specific functions and are classified into:

- Analog ICs: Process continuous signals for applications like amplifiers and filters.

- Digital ICs: Handle discrete signals for computing and logic operations.

- Mixed-Signal ICs: Combine analog and digital functions for versatile applications like audio processing and communication systems.

ICs are found in various devices, from smartphones and computers to automotive systems and industrial equipment.

Characteristics and Applications

Active components play critical roles in signal rectification, amplification, switching, and logic operations. Their unique characteristics enable their use in diverse applications, such as:

- Power Electronics: Manage energy in devices like converters and motor controllers.

- Signal Processing: Amplify and filter signals in audio, video, and communication systems.

- Computing Devices: Form the core of processors, memory chips, and microcontrollers.

- Consumer Electronics: Drive the functionality of gadgets like TVs, smartphones, and smart home devices.

Advances in semiconductor technology have significantly improved the performance, efficiency, and size of active components. These innovations continue to drive the development of more powerful and compact electronic systems, shaping the future of technology.

Connectors and Terminals on Circuit Boards

Connector Structure and Design

Circuit board connectors typically consist of a main body, a first connecting portion for one board, and a second connecting portion for the other. Manufacturers use conductive plate materials with plating layers on both sides to create these connectors. The second connecting portion often has an annular cross-section for enhanced connectivity. The connector housing is mounted opposite the circuit board’s terminal face, ensuring efficient alignment and connection.

Terminal Types and Configurations

- Signal Terminals: Designed for transmitting data or signals between boards.

- Power Supply Terminals: Feature larger lock portions for secure connections with mating connectors.

Each terminal typically has three key components.

- Contact Point: Ensures reliable contact with the counterpart terminal.

- Board Connecting Part: Allows soldering to the circuit board wiring.

- Solder Barrier: Prevents solder from spreading beyond the designated area, ensuring clean connections.

Terminal-to-Board Connection

Terminals are arranged through the connector housing, with:

- One End: Acting as the connector terminal that contacts the circuit terminal part.

- Other End: Serving as the board fixing portion soldered to the circuit board.

To optimize connectivity, circuit boards have:

- First Terminals: Located on one surface, connected to the first wiring layer.

- Second Terminals: Positioned on the opposite surface, connected to the second wiring layer. These terminals are arranged to avoid vertical overlap, ensuring clear connections with the connector contact portions.

Stress Absorption and Locking Mechanisms

To handle mechanical stress, terminals feature a coupling portion between the press-fitting and board fixing sections. A center hole in this portion absorbs stress by deforming under pressure. Additionally:

- Power Supply Terminal Lock Portions: Larger than signal terminal locks for more secure connections with mating connectors.

- Signal Terminal Locks: Provide stable connections while allowing precise alignment.

5. Versatile Conductor Connection

Some terminals include a through-opening with an edge for conductor clamping. A clamping spring securely holds conductors from various spatial directions. This design reduces material usage and improves current transfer compared to flat contact surfaces.

How Circuit Board Components Work Together in Electronics

1. Signal Flow

First, the traces on the circuit board act as pathways for electrical signals, enabling them to travel efficiently between components. These signals carry critical information, power, or control instructions, which are necessary for the components to perform their tasks. Without this seamless signal flow, the device’s operation would become unreliable.

2. Component Interconnections

Next, solder joints establish vital electrical connections between the components’ terminals and the pads or lands on the wiring layer. This connection ensures that components can exchange signals or data through the network of traces. Moreover, these interconnections allow the components to work in sync, enhancing the overall performance of the circuit board.

3. Power Distribution

In addition, power traces distribute energy from the source, such as a battery or power supply, to all components requiring power. This even distribution ensures each component receives the necessary energy to operate without disruptions. As a result, the entire circuit board functions consistently and efficiently.

4. External Interfacing

Furthermore, connectors play a crucial role in facilitating interactions with external devices or systems. These connectors allow the exchange of signals, data, or power, enabling the circuit board to interface with peripherals such as sensors, displays, or external modules. This connectivity significantly expands the functionality and versatility of the board.

5. Mechanical Support

Finally, the circuit board provides a stable and rigid platform to mount and secure electronic components. Its structure ensures the components remain in place during operation. Additionally, mounting holes allow secure attachment to enclosures or chassis, protecting the board and its components from environmental factors and physical damage.

Applications of Circuit Board Components

1. Consumer Electronics

Circuit board assemblies are at the core of everyday devices such as TVs, smartphones, computers, and home appliances. They enable these products to perform complex tasks efficiently. Furthermore, their compact designs support the miniaturization of gadgets, making devices more portable and user-friendly.

2. Automotive Electronics

In the automotive sector, circuit boards play a vital role in systems like engine control units, infotainment systems, and sensors. They help monitor and control vehicle performance while enhancing safety and comfort. Additionally, their integration into advanced driver-assistance systems (ADAS) supports the development of autonomous vehicles.

3. Industrial Control Systems

Industrial environments rely on circuit board assemblies for precision and automation. They power programmable logic controllers, motor drives, and other control systems that ensure seamless operations in manufacturing and production facilities. These boards are also built to withstand harsh conditions, ensuring reliability in demanding settings.

4. Aerospace and Defense

Circuit boards are crucial in aerospace and defense applications, where reliability and performance are paramount. They are used in avionics, radar systems, and communication equipment, enabling precise navigation, real-time communication, and robust defense mechanisms. Their ability to operate in extreme conditions makes them ideal for these critical industries.

5. Medical Devices

In the medical field, circuit board assemblies are vital for patient monitoring systems, imaging equipment, and therapeutic devices. They ensure accuracy and reliability in life-saving technologies, supporting healthcare professionals in delivering quality care. As medical technology advances, circuit boards continue to play a central role in innovative solutions.

To get detailed scientific explanations of circuit board components, try Patsnap Eureka.