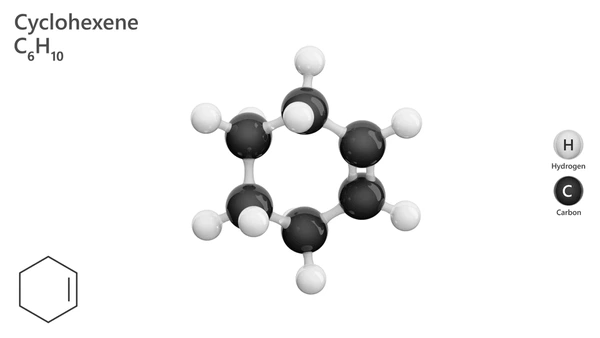

Cyclohexene is a flammable, colorless liquid with the formula C₆H₁₀. It belongs to the alkene family and contains a six-membered ring with one double bond. Because of this structure, cyclohexene reacts easily in chemical processes. Manufacturers and researchers value it as an intermediate in organic synthesis, particularly in the production of nylon and other polymers. This article explores how C₆H₁₀ is used in different industries, what makes it chemically useful, and why it continues to be a core raw material in modern manufacturing.

What Is Cyclohexene?

What is cyclohexene used for? Eureka Technical Q&A explains its role as an intermediate in the production of nylon, resins, and plasticizers, highlighting its importance in chemical manufacturing and industrial applications.

Cyclohexene is a cyclic hydrocarbon that contains one double bond within a six-carbon ring. It usually forms through the partial hydrogenation of benzene or the dehydration of cyclohexanol. Its chemical reactivity, especially in addition and oxidation reactions, makes it highly valuable in both academic and industrial chemistry.

Key Properties of Cyclohexene

| Property | Description |

|---|---|

| Chemical Formula | C₆H₁₀ |

| Molar Mass | 82.15 g/mol |

| Boiling Point | 83°C |

| Solubility | Insoluble in water; soluble in organic solvents |

| Structure | Six-carbon ring with one double bond |

| Reactivity | Highly reactive in alkene-type reactions |

These properties allow cyclohexene to serve as both a solvent and a reactive intermediate in chemical synthesis.

Major Uses of Cyclohexene

C₆H₁₀ plays a crucial role in chemical manufacturing due to its versatility and reactivity. It supports several industries, from polymers to pharmaceuticals, through its many valuable derivatives.

Intermediate in Chemical Synthesis

Chemical manufacturers use cyclohexene as an essential intermediate. They convert it into cyclohexane, which then helps produce adipic acid and caprolactam. These two compounds serve as building blocks for nylon-6 and nylon-6,6. These durable materials support applications in textiles, automotive components, electronics, and packaging.

Production of Epoxy Resins

Oxidation of cyclohexene produces C₆H₁₀ oxide. This compound acts as a primary raw material in epoxy resin manufacturing. Paint, adhesive, and industrial coating producers depend on these resins for high-performance applications.

Pharmaceuticals and Fragrance Synthesis

Chemical producers use cyclohexene and its derivatives in the development of pharmaceutical ingredients. These derivatives also contribute to fragrances, helping perfumers create complex scent profiles for perfumes and personal care products.

Petrochemical Industry Applications

The petrochemical industry converts cyclohexene into cyclohexylbenzene. This compound supports phenol production, a crucial ingredient in epoxy resin and plastic manufacturing.

Catalytic Process Development

Researchers use cyclohexene in catalytic reactions to create various hydrocarbons and chemicals. These processes aim to increase product yield and selectivity using optimized catalysts.

Research and Development Use

Scientists frequently study cyclohexene in R&D labs. They use it as a model compound to test catalyst performance in oxidation reactions and to develop more efficient catalytic materials.ds improve flexibility, temperature tolerance, and resistance to oxidation.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Cyclohexanone Production Process ExxonMobil Chemical Patents, Inc. | Efficient separation of cyclohexanone and phenol through selective hydrogenation, balancing supply and demand | Industrial production of cyclohexanone for nylon manufacturing |

| Antrodia Camphorata Extract Golden Biotechnology Corp. | Isolation of 4-hydroxy-2,3-dimethoxy-6-methyl-5(3,7,11-trimethyl-dodeca-2,6,10-trienyl)-cyclohex-2-enone with anti-tumor and antioxidant properties | Cancer treatment, particularly breast, hepatic, and prostate cancers |

| Zeolite-based Catalyst for Cyclohexene Isomerization Kara Technology, Inc. | High selectivity and stability for methylcyclopentene production from cyclohexene | Efficient and cost-effective production of methylcyclopentene in petrochemical industry |

| Solvent-free Cyclohexanone Production International Flavors & Fragrances, Inc. | High efficiency cyclohexanone production using transition metals and inorganic metal salts catalyst in a solvent-free reactor | Environmentally friendly production of cyclohexanone for fragrances and flavors |

| Cyclohexene Production Process UOP LLC | High yield and economically feasible cyclohexene production using solid acidic catalyst like sodium Y-zeolite | Efficient production of cyclohexene for use in various chemical industries |

Why Cyclohexene Is Industrially Important

Demand for nylon continues to rise in the automotive, electronics, and apparel sectors. As a result, cyclohexene remains in high demand as a feedstock. Additionally, research laboratories use it as a reliable test material in alkene chemistry due to its manageable reactivity and availability.

Its ability to serve multiple functions—reactive intermediate, solvent, and monomer—makes it a core chemical in both mass production and fine chemical synthesis.

Safety and Handling Considerations

Cyclohexene is highly flammable and evaporates quickly. Store it in tightly sealed containers away from heat and sunlight. Long-term exposure to air can form peroxides, which are explosive. Always handle it in well-ventilated spaces and wear protective gear.

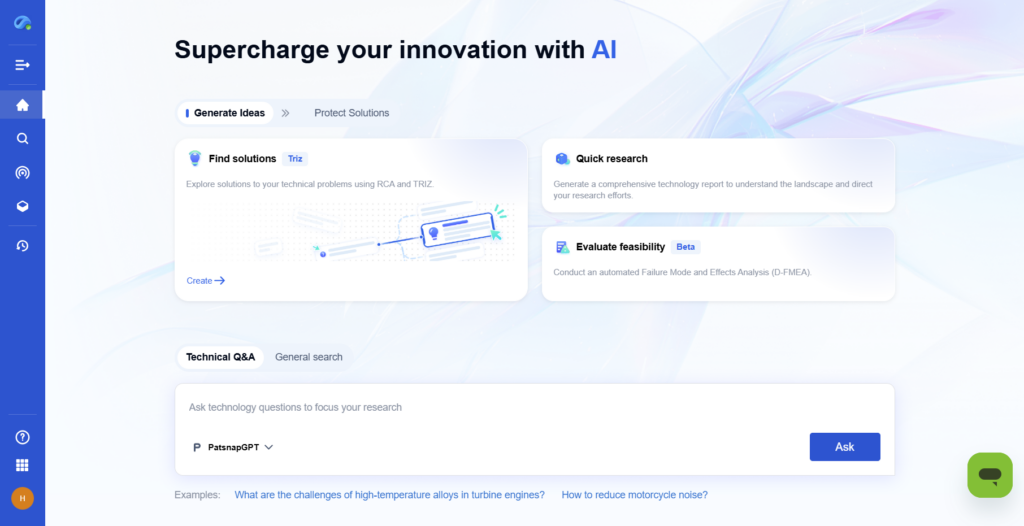

How Eureka Enhances Cyclohexene Research and Innovation

Eureka by PatSnap is an AI-powered innovation intelligence platform that supports R&D professionals in tracking emerging technologies, analyzing patents, and accelerating discovery—especially in chemical synthesis and industrial applications.

- Patent Discovery: Eureka surfaces the latest patents involving C₆H₁₀ use in polymer production, fragrance synthesis, and pharmaceutical intermediates, keeping researchers informed on global innovation.

- Market & Trend Analysis: The platform identifies trends in industries using C₆H₁₀—such as coatings, nylon manufacturing, and fine chemicals—offering insights into where demand is growing.

- Competitor Benchmarking: Eureka helps chemical companies analyze how competitors are applying C₆H₁₀ in formulations or catalytic processes, informing strategic R&D direction.

- Technical Landscape Mapping: With AI-driven clustering, Eureka visualizes research hotspots related to C₆H₁₀ derivatives and their potential applications in green chemistry or specialty materials.

FAQs

What is cyclohexene used for in labs?

Chemists use it to demonstrate bromination, hydrogenation, and oxidation because of its clear alkene behavior.

Is cyclohexene different from cyclohexane?

Yes. Cyclohexane is fully saturated with single bonds, while cyclohexene has a double bond, making it more reactive.

Does cyclohexene help make nylon?

Yes. It leads to cyclohexanol and cyclohexanone, which are critical steps in nylon-6 production.

Can you use cyclohexene as a solvent?

In some cases, yes. It works best for dissolving non-polar compounds during separation and purification.

Is it dangerous?

It can be, if mishandled. It’s flammable and may form explosive peroxides over time. Always follow safety protocols.

Conclusion

Cyclohexene is a flexible and reactive compound with critical roles in polymer production, organic synthesis, and industrial formulations. From helping create nylon to serving as a solvent or chemical intermediate, it remains a valuable building block in chemistry. Its fast reactivity, accessibility, and compatibility with various reactions ensure that C₆H₁₀ will continue to support innovation in both research and manufacturing sectors.

To get detailed scientific explanations of Cyclohexene, try Patsnap Eureka.