TPE Biodegradability Goals and Background

Thermoplastic elastomer (TPE) is a class of polymeric materials that combine the properties of thermoplastics and elastomers, offering a unique combination of flexibility, elasticity, and processability. The biodegradability and recyclability of TPEs have become increasingly important due to growing environmental concerns and the need for sustainable materials. The primary goal of enhancing the biodegradability and recyclability of TPEs is to reduce their environmental impact and promote a circular economy. Biodegradable TPEs can be broken down by microorganisms into natural substances, reducing waste accumulation and minimizing their carbon footprint. Recyclable TPEs, on the other hand, can be reprocessed and reused, conserving resources and reducing the need for new raw materials.

The development of biodegradable and recyclable thermoplastic elastomer (TPE) has been driven by various factors, including stricter environmental regulations, consumer demand for eco-friendly products, and the need for sustainable solutions in industries such as automotive, construction, and packaging. Additionally, the depletion of non-renewable resources and the increasing awareness of the environmental impact of plastic waste have further fueled the demand for more sustainable TPE materials. Enhancing the biodegradability and recyclability of TPEs requires a multifaceted approach that involves material design, processing techniques, and end-of-life management strategies. Researchers and manufacturers are exploring various avenues such as incorporating biodegradable polymers, developing new additives and fillers, optimizing processing conditions, and implementing effective recycling and recovery systems.

To get a detailed scientific explanations of tpe, try Eureka.

Market Demand for Sustainable TPE Materials

The market demand for sustainable thermoplastic elastomer (TPE) materials has been steadily increasing in recent years, driven by growing environmental concerns and regulatory pressures to reduce plastic waste and promote a circular economy. Consumers and industries alike are seeking eco-friendly alternatives to traditional plastics, creating a significant opportunity for biodegradable and recyclable TPE materials.

One of the key drivers for sustainable TPE materials is the need to address the environmental impact of plastic pollution. Conventional plastics, including TPEs, are non-biodegradable and can persist in the environment for hundreds of years, contributing to the accumulation of plastic waste in landfills, oceans, and natural habitats. Biodegradable TPEs offer a solution by breaking down into natural components, reducing the environmental burden and promoting a more sustainable material lifecycle. Additionally, the increasing emphasis on circular economy principles and resource efficiency has fueled the demand for recyclable TPE materials. Recyclable TPEs can be collected, processed, and reused in new products, reducing the need for virgin materials and minimizing waste generation. This not only contributes to environmental sustainability but also offers potential cost savings and resource efficiency benefits for manufacturers.

The automotive industry, a major consumer of TPE materials, has been actively seeking sustainable alternatives to meet stringent environmental regulations and consumer preferences for eco-friendly vehicles. The demand for biodegradable and recyclable TPE materials in automotive applications such as interior trim, sealing systems, and wire and cable coatings is expected to grow significantly in the coming years. Similarly, the packaging industry, which has been under scrutiny for its contribution to plastic waste, is actively exploring sustainable TPE materials as an alternative to traditional plastics. Biodegradable and recyclable TPE materials can be used in various packaging applications, including food containers, protective packaging, and flexible packaging solutions, reducing the environmental impact of single-use plastics. Furthermore, the increasing consumer awareness and demand for environmentally responsible products have driven the adoption of sustainable TPE materials across various industries, including consumer goods, construction, and healthcare. Manufacturers are recognizing the competitive advantage of offering eco-friendly products and are actively seeking sustainable material solutions to meet consumer expectations and differentiate themselves in the market.

Overall, the market demand for sustainable TPE materials is driven by a combination of regulatory pressures, environmental concerns, and consumer preferences for eco-friendly products. As the global push towards sustainability and circular economy principles continues, the adoption of biodegradable and recyclable TPE materials is expected to accelerate, creating significant growth opportunities for innovative material solutions in this space.

Current State and Challenges in TPE Biodegradability

Thermoplastic elastomer (TPE) have gained significant attention in recent years due to their unique combination of properties, including elasticity, flexibility, and processability. However, the biodegradability and recyclability of these materials have emerged as critical challenges that need to be addressed to promote sustainability and environmental responsibility.

Currently, most commercially available TPEs are derived from non-renewable fossil resources such as petroleum-based polymers, making them non-biodegradable and difficult to recycle. These materials can persist in the environment for extended periods, contributing to the accumulation of plastic waste and posing potential risks to ecosystems and human health. One of the major challenges in enhancing the biodegradability of TPEs lies in their complex chemical structure and composition. TPEs are typically composed of a hard thermoplastic phase and a soft elastomeric phase, which are chemically incompatible and require compatibilizers or other additives to achieve the desired properties. This complexity makes it difficult to design TPEs that can be readily broken down by microorganisms or natural processes.

Additionally, the presence of various additives such as plasticizers, fillers, and stabilizers can further hinder the biodegradability of TPEs. These additives are often non-biodegradable themselves and can interfere with the degradation process, leading to the formation of microplastics or other persistent residues. Regarding recyclability, TPEs face challenges due to their inherent heterogeneity and the potential presence of contaminants or additives. Effective recycling processes often require precise sorting and separation techniques, which can be challenging and costly for TPEs with varying compositions and properties. Furthermore, the geographic distribution of TPE production and consumption can also impact the feasibility of recycling efforts. Regions with well-established recycling infrastructure and regulations may have better opportunities for TPE recycling, while areas lacking such systems may face greater challenges in managing TPE waste effectively.

To address these challenges, ongoing research efforts are focused on developing biodegradable and recyclable TPE materials through various approaches such as incorporating bio-based or biodegradable polymers, exploring novel compatibilization strategies, and optimizing recycling processes for specific TPE compositions.

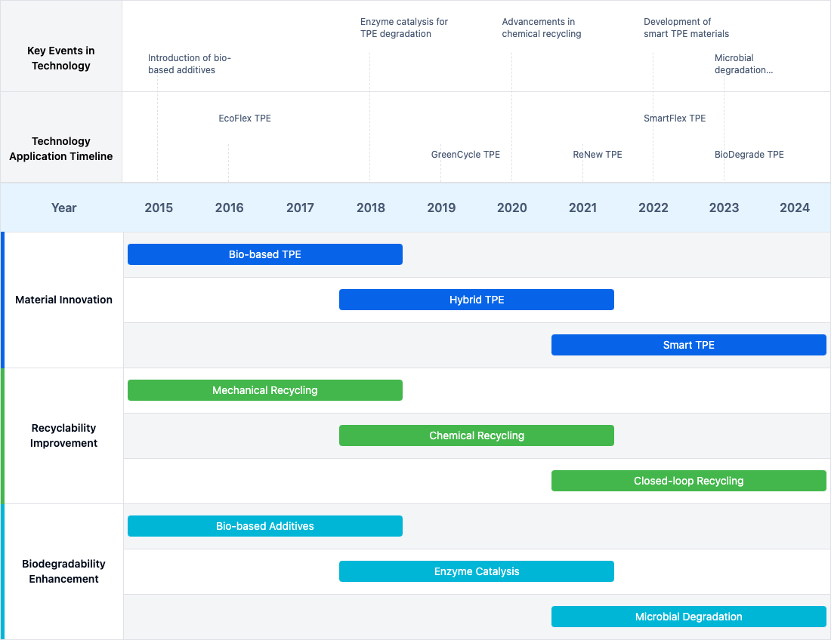

Evolution of TPE Recycling Technologies

Existing Solutions for TPE Biodegradability and Recycling

TPE Materials with Biodegradable Properties

Some TPE materials are designed to be biodegradable, meaning they can be broken down by microorganisms into natural substances. This can be achieved by incorporating biodegradable components or additives into the TPE formulation. Biodegradable TPEs offer an environmentally friendly alternative to traditional non-biodegradable plastics.

Recycling and Reuse of TPE Materials

TPE materials can be recycled and reused, reducing waste and promoting sustainability. Recycling processes involve collecting, sorting, and reprocessing used TPE products into new materials or products. This approach helps to conserve resources and minimize the environmental impact of TPE production and disposal.

TPE Materials with Improved Thermal and Mechanical Properties

Some TPE materials are designed to have enhanced thermal and mechanical properties such as high temperature resistance, wear resistance, and scratch resistance. These improved properties make the TPEs suitable for various applications, including automotive, construction, and electrical industries where durability and performance are crucial.

TPE Materials for Specific Applications

TPE materials can be tailored for specific applications such as medical devices, automotive components, and consumer products. These specialized TPEs may incorporate antimicrobial, antistatic, or other functional properties to meet the requirements of the intended application.

Recycling and Recovery of TPE Materials

TPE materials can be recycled and recovered through various processes such as mechanical recycling, chemical recycling, or energy recovery. Mechanical recycling involves collecting, sorting, and reprocessing TPE waste into new products. Chemical recycling breaks down TPE materials into their chemical constituents for reuse. Energy recovery involves burning TPE waste to generate energy.

Biodegradable and Environmentally Friendly TPE Materials

Efforts have been made to develop biodegradable and environmentally friendly TPE materials to address the issue of recyclability and sustainability. These materials can be derived from renewable sources or designed to be more easily biodegradable, reducing their environmental impact.

Improved TPE Material Formulations for Enhanced Properties

Researchers have focused on developing improved TPE material formulations with enhanced properties such as heat resistance, wear resistance, and scratch resistance. These improved formulations can extend the lifespan and applications of TPE products, potentially reducing the need for frequent replacement and waste generation.

Composite and Blended TPE Materials

Researchers have explored the development of composite and blended TPE materials by combining TPE with other materials such as fillers, reinforcements, or other polymers. These composite and blended materials can exhibit enhanced properties or unique characteristics tailored for specific applications.

TPE Materials with Improved Processing and Manufacturing

Some TPE materials are designed to facilitate efficient processing and manufacturing, such as improved extrusion, molding, or adhesion properties. These TPE materials may incorporate additives or have specific formulations that enhance their processability, enabling easier and more cost-effective production of TPE-based products.

Key Players in TPE Industry

The biodegradability and recyclability of Thermoplastic Elastomer Materials (TPE) have become increasingly important due to growing environmental concerns and sustainability goals. Several key players have emerged in this field, focusing on developing innovative solutions to enhance the eco-friendly properties of TPEs. These players range from established companies to academic institutions, each contributing unique approaches and technologies.

Natural Fiber Welding Inc.

Natural Fiber Welding Inc. has published 3 patents related to the biodegradability and recyclability of TPEs. Their technology focuses on incorporating natural fibers into TPE matrices, potentially improving biodegradability while maintaining desirable mechanical properties. By leveraging renewable resources and exploring novel material combinations, Natural

Fiber Welding Inc. aims to develop sustainable and environmentally friendly TPE solutions. Potential applications of Natural Fiber Welding Inc.’s technology include packaging materials, automotive components, consumer goods, and other industries where biodegradable and recyclable TPEs are in demand.

Roquette Frères SA

Roquette Frères SA has published 2 patents in the field of TPE biodegradability and recyclability. Their research focuses on developing bio-based and biodegradable TPEs derived from renewable resources such as plant-based polymers. By exploring alternative feedstocks and innovative material formulations, Roquette Frères SA aims to reduce the environmental impact of TPEs while maintaining their desirable properties. Potential applications of Roquette Frères SA’s technology include packaging materials, agricultural films, disposable products, and other applications where biodegradable and renewable TPEs are preferred.

Hiroshima University

Hiroshima University has published 2 patents related to the biodegradability and recyclability of TPEs. Their research efforts are likely focused on exploring novel material compositions, processing techniques, or chemical modifications to enhance the biodegradability and recyclability of TPEs. Academic institutions often contribute fundamental research and innovative approaches that can drive advancements in this field. Potential applications of Hiroshima University’s research could span various industries, including packaging, automotive, construction, and consumer goods where biodegradable and recyclable TPEs are desirable.

Institute of Chemical Technology

The Institute of Chemical Technology has published 1 publication related to TPE biodegradability and recyclability. Their research focuses on studying the mechanical, thermal, and morphological properties of TPE composites reinforced with natural fibers such as coconut pith. By incorporating renewable and biodegradable fillers into TPE matrices, they aim to enhance the sustainability and eco-friendly properties of these materials. Potential applications of the Institute of Chemical Technology’s research could include automotive components, construction materials, and consumer goods where natural fiber-reinforced TPE composites with improved biodegradability and recyclability are desired.

Cochin University of Science & Technology

Cochin University of Science & Technology has published 3 publications related to TPE biodegradability and recyclability. Their research focuses on studying the mechanical, thermal, and morphological properties of TPE composites reinforced with natural fibers such as coconut pith. By incorporating renewable and biodegradable fillers into TPE matrices, they aim to enhance the sustainability and eco-friendly properties of these materials while maintaining desirable performance characteristics. Potential applications of Cochin University of Science & Technology’s research could include automotive components, construction materials, and consumer goods where natural fiber-reinforced TPE composites with improved biodegradability and recyclability are desired.

Core Innovations in TPE Sustainability

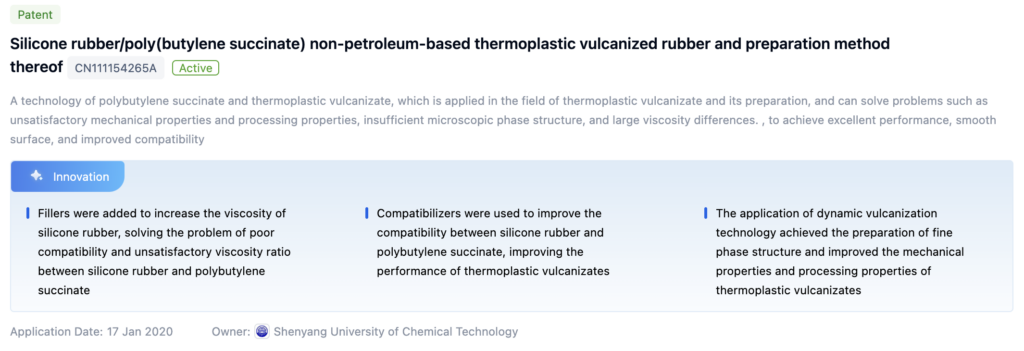

Patent 1: Silicone Rubber/Poly(butylene succinate) Non-Petroleum-Based Thermoplastic Vulcanized Rubber and Preparation Method Thereof

- Core Invention Points:

- Fillers were added to increase the viscosity of silicone rubber, solving the problem of poor compatibility and unsatisfactory viscosity ratio between silicone rubber and polybutylene succinate.

- Compatibilizers were used to improve the compatibility between silicone rubber and polybutylene succinate, improving the performance of thermoplastic vulcanizates.

- Dynamic vulcanization technology achieved the preparation of fine phase structure and improved the mechanical properties and processing properties of thermoplastic vulcanizates.

Patent 2: Method for Manufacturing a Closure for a Product-Retaining Container

- Core Invention Points:

- Natural cork as the material for the closure to address leakage and spoilage issues during wine bottle loading.

- Design and manufacture a wine bottle stopper that can withstand the pressure increase that may occur during the bottle tilting or neck-down process after the wine product is bottled.

- Low oxygen permeability to extend the shelf life and freshness of the product.

Paper 1: Studies in Mechanical Thermal and Morphological Analysis of EPDM/Polypropylene Coconut Pith Composites

- Core Invention Points:

- Investigates the morphology thermal behavior and mechanical properties of EPDM/polypropylene coconut pith composites.

- Coconut pith, an eco-friendly and cost-effective filler is added in different ratios to EPDM/polypropylene thermoplastic vulcanizates using a Brabender Plasticorder.

Future Directions in TPE Biodegradability

Biodegradable TPE Materials

Some TPE materials are designed to be biodegradable, making them more environmentally friendly. These materials can break down into natural components over time, reducing their environmental impact. Biodegradable TPE materials may incorporate natural or bio-based components such as plant-derived polymers or additives.

Recycling and Recovery of TPE Materials

TPE materials can be recycled or recovered for reuse, reducing waste and promoting a circular economy. Various techniques and processes have been developed for recycling or recovering TPE materials such as mechanical recycling, chemical recycling, or energy recovery through incineration.

TPE Materials with Improved Biodegradability and Recyclability

Researchers and manufacturers have focused on developing TPE materials that combine both biodegradability and recyclability. These materials aim to strike a balance between environmental sustainability and resource efficiency, allowing for biodegradation under specific conditions while also enabling recycling or recovery processes.

Environmental Impact of TPE Materials

Thermoplastic elastomers (TPEs) are a class of polymeric materials that combine the properties of thermoplastics and elastomers, offering a unique combination of flexibility, elasticity, and processability. While TPEs offer numerous advantages over traditional materials, their environmental impact is a crucial consideration in the pursuit of sustainability.

TPEs are generally derived from non-renewable fossil resources such as petroleum or natural gas, which raises concerns about their carbon footprint and depletion of finite resources. Additionally, the production processes involved in manufacturing TPEs can contribute to greenhouse gas emissions, energy consumption, and the generation of hazardous waste. The biodegradability of TPEs is a significant challenge as most TPEs are not readily biodegradable in natural environments. This means that TPE products, once discarded, can persist in landfills or the environment for extended periods, contributing to plastic pollution and environmental degradation. The lack of biodegradability also hinders the adoption of TPEs in applications where biodegradability is a critical requirement, such as in the agricultural or medical sectors. Recyclability is another area of concern for TPEs. While some TPEs can be mechanically recycled, the process is often complex and energy-intensive, and the resulting recycled material may have compromised properties. Chemical recycling, which involves breaking down the polymer chains into their monomeric building blocks, is an emerging technology that holds promise for TPE recycling, but it is still in the early stages of development and faces challenges in terms of scalability and economic viability.

To address these environmental concerns, researchers and manufacturers are exploring various strategies such as the development of bio-based or biodegradable TPEs, the incorporation of sustainable additives or fillers, and the optimization of recycling processes. Additionally, the adoption of circular economy principles, which emphasize the reuse and recovery of materials, can contribute to reducing the environmental impact of TPEs throughout their lifecycle.

Regulatory Landscape for Sustainable TPE

The regulatory landscape for sustainable TPE materials is a crucial aspect that needs to be carefully considered. Governments and regulatory bodies around the world have implemented various policies and guidelines to promote environmentally friendly practices and reduce the impact of plastic waste on the environment.

In the European Union, the Plastics Strategy and the Single-Use Plastics Directive aim to promote the circular economy and reduce the environmental impact of plastics. These regulations encourage the development of biodegradable and recyclable plastics, including TPE materials. The EU has also set targets for the recycling and recovery of plastic waste, which could drive the demand for more sustainable TPE solutions. In the United States, the Environmental Protection Agency (EPA) has established guidelines for the proper disposal and recycling of plastics, including TPE materials. Additionally, several states have implemented their own regulations and initiatives to address plastic waste, such as bans on single-use plastics and extended producer responsibility programs. In Asia, countries like China, Japan, and South Korea have implemented various regulations and policies to promote the development of eco-friendly plastics and reduce plastic waste. For example, China has implemented a ban on certain types of single-use plastics and has set targets for the recycling and recovery of plastic waste. Furthermore, international organizations such as the United Nations Environment Programme (UNEP) and the Organization for Economic Co-operation and Development (OECD) have developed guidelines and frameworks to promote sustainable plastic production and waste management practices.

It is essential for companies operating in the TPE industry to stay up-to-date with the latest regulations and guidelines in their respective markets. Compliance with these regulations can not only help companies avoid potential fines and penalties but also position them as environmentally responsible and sustainable players in the market.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!