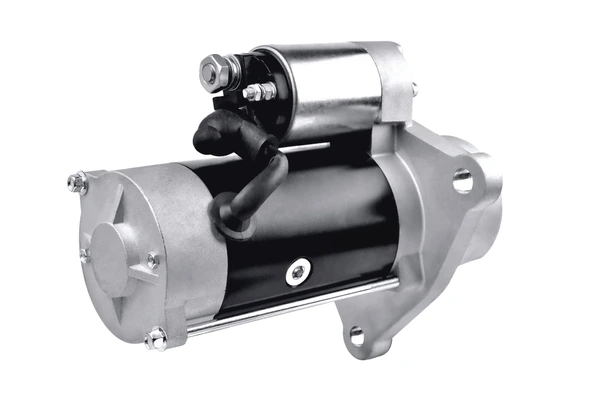

What Is a Starter Motor?

A starter motor is a key automotive component that converts battery power into mechanical energy to start an engine. Designed for heavy-duty operation, it quickly cranks the engine by engaging its pinion with the flywheel. Despite operating for just 1-3 seconds per start, it handles significant mechanical and electrical stress. This article will explore how starter motors work, their key components, common issues, and modern advancements.

How a Starter Motor Works

Basic Principle

A starter delivers high power in a compact form to rotate the engine crankshaft during startup. It transfers rotational energy through a pinion gear that meshes with the flywheel attached to the crankshaft. This process ensures the engine reaches the minimum speed required to begin combustion and sustain its operation.

Operational Process

Turning the ignition key activates a solenoid, engaging the drive assembly to connect the pinion gear with the flywheel. This engagement allows the starter to transmit rotational force, cranking the engine to start.

The motor runs for about 1-3 seconds during each attempt, enduring high torque, especially during cylinder compression strokes. After the engine starts, the solenoid disengages, and a spring mechanism returns the drive assembly to its resting position. The armature coasts to a stop within seconds, completing the process efficiently. This straightforward yet powerful mechanism ensures quick and reliable engine startups.

Types of Starter Motors

1. Permanent Magnet Systems

- Utilize permanent magnets to create a stable magnetic field.

- Include auxiliary poles to enhance torque and optimize energy use.

- Offer improved efficiency and performance for modern applications.

2. Dual Synchronized Systems

- Feature two systems working together, each with its own pinion engaging the ring gear.

- Provide simultaneous engagement, ensuring smoother cranking and reduced wear on components.

- Enhance startup efficiency, particularly for heavy-duty engines.

3. Soft Start Controllers

- Not traditional motors but devices that control motor startups.

- Reduce inrush current and torque surges, offering smoother and safer operation.

- Commonly used to protect connected equipment from mechanical and electrical stress.

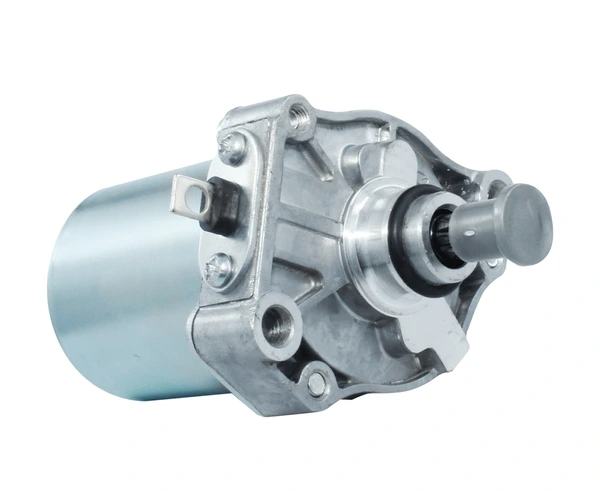

4. Electric Systems for Combustion Engines

- Designed to crank the engine’s crankshaft efficiently.

- Include components like motors, pinions, and sealing caps for internal protection.

- Advanced models feature reinforced structures for durability and better performance.

5. Dynamic Coupling Innovations

- Use advanced mechanical connections to improve startup efficiency.

- Reduce emissions, making them suitable for eco-friendly applications like start-stop systems.

- Offer precise control over the starting process.

6. Single-Phase and Three-Phase Induction Motors

- Primarily used in industrial settings for heavy-duty applications.

- Require starting mechanisms to manage high inrush currents during startup.

- Provide reliable operation in demanding environments.

Common Starter Motor Problems and Solutions

Battery Charge Problems

- Issue: Low battery charge can make it challenging to start the engine efficiently.

- Solution: Use advanced control systems capable of detecting and addressing starter malfunctions. Dual starter designs ensure reliable performance, even in critical conditions.

Excessive Noise and Wear

- Issue: Traditional systems often produce loud noise and experience wear due to high electrical and mechanical stress.

- Solution: Install current-limiting mechanisms to prevent battery voltage drops. Use clutches that smooth out starting processes, reducing vibrations and extending component life.

Short Circuit and Overheating

- Issue: Gear collisions or repeated use can cause short circuits and overheating, leading to frequent malfunctions.

- Solution: Incorporate a breaking section with the coil to interrupt electrical flow during a short circuit. This prevents overheating and ensures consistent performance.

High Inrush Current Stress

- Issue: High inrush currents can strain components, causing mechanical and thermal damage over time.

- Solution: Use soft starters or systems that regulate starting currents to minimize torque surges. This approach reduces stress on the power supply and internal components.

Durability Challenges in Modern Vehicles

- Issue: Frequent start-stop cycles in vehicles with idle-stop systems cause excessive wear on starters.

- Solution: Equip starters with shock-absorbing devices and one-way clutches to minimize impact during gear engagement, extending durability.

System Reliability Concerns

- Issue: Traditional systems lack redundancy, making them prone to complete failure during starter faults.

- Solution: Implement redundant starter setups with sensors to monitor system health. This ensures smooth engine starts, even if one starter fails.

How Much Does a Starter Motor Cost?

The cost of a starter motor can vary widely depending on factors such as the vehicle type, quality, brand, and whether it’s new, rebuilt, or remanufactured. Here’s a breakdown of typical costs:

New Starter Motor

- Cost Range: $100 to $500 or more.

- Factors Affecting Price:

- High-performance or specialty vehicles often require more expensive starter motors.

- Premium brands, such as Bosch or Denso, generally cost more due to reliability and performance.

Rebuilt or Remanufactured Starter Motor

- Cost Range: $50 to $300.

- Key Benefits:

- Offers a more affordable option while maintaining quality.

- Rebuilt motors often come with warranties, making them a reliable budget-friendly choice.

Labor Costs for Installation

- Average Cost: $150 to $400.

- Factors Influencing Labor Costs:

- The complexity of accessing and replacing the motor can increase labor charges.

- Luxury or older vehicles may require specialized expertise, raising the overall cost.

Additional Costs

- Diagnostic fees to confirm starter issues: $50 to $100.

- Core charges for rebuilt motors: $20 to $50, refundable upon returning the old unit.

How to Save on Starter Motor Costs

- Compare Options: Check prices for new, rebuilt, and aftermarket starter motors.

- DIY Installation: If skilled, replacing the motor yourself can save on labor costs.

- Warranty Coverage: Verify if your vehicle’s warranty covers starter motor replacements.

Maintenance Tips for Prolonging Starter Motor Life

Oil and Fluid Checks

Keep the motor well-lubricated to prevent unnecessary wear on moving parts. Regularly check oil and fluid levels as part of routine maintenance. Following the recommended schedule for fluid changes ensures smooth operation and helps avoid damage over time.

Brush Replacement

Inspect the motor’s brushes periodically, as they can wear down due to electrical arcing. Replacing worn brushes promptly can improve performance and significantly increase the motor’s lifespan. Proactive maintenance reduces the risk of unexpected failures.

Conclusion: Importance of a Healthy Starter Motor

A well-maintained starter motor is essential for reliable vehicle performance and a smooth start every time. Regular inspections, timely repairs, and proper care can extend its lifespan and prevent costly breakdowns. By prioritizing maintenance, you ensure your vehicle remains dependable, efficient, and ready to go whenever you need it.

To get detailed scientific explanations of Starter Motor, try Patsnap Eureka.