What Is Electric Power Steering?

Electric Power Steering (EPS) is an advanced steering technology that enhances driving comfort and precision. By using an electric motor instead of a hydraulic system, EPS reduces steering effort and improves efficiency. Controlled by an Electronic Control Unit (ECU), it dynamically adjusts assistance based on factors like steering angle, torque, and vehicle speed. In this article, we’ll explore how EPS works, its benefits, and why it’s becoming a standard feature in modern vehicles.

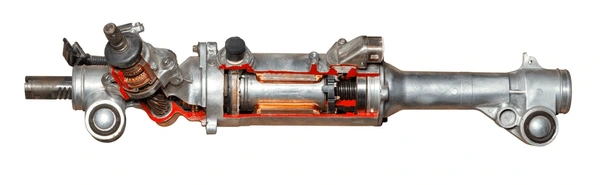

Key Components of Electric Power Steering (EPS)

Assisting Electric Motor

The electric motor delivers the steering assistance needed based on input from sensors like vehicle speed and steering torque. It adjusts seamlessly to ensure a smooth driving experience.

Power Supply Source

The motor draws power from the vehicle’s battery, with the Electronic Control Unit (ECU) managing and distributing the energy effectively for optimal performance.

Sensors

Essential sensors, including a steering torque sensor, vehicle speed sensor, and sometimes a yaw rate sensor, collect real-time data. These inputs allow precise adjustments for a responsive steering experience.

Electronic Control Unit (ECU)

The ECU processes sensor data and controls the motor, delivering the right amount of assistive torque. It adapts dynamically to changing driving conditions, enhancing both safety and comfort.

How Electric Power Steering Works

When the driver turns the steering wheel, a torque sensor detects the applied force and sends data to the ECU. The ECU analyzes the torque and vehicle speed to calculate the required level of steering assistance. Using this data, it controls the electric motor, which applies the necessary force to the steering column or rack. The system dynamically adjusts support, offering more assistance at low speeds, such as during parking, and less at higher speeds for improved stability.

Differences Between Electric and Hydraulic Power Steering

Operational Principles

- Hydraulic Power Steering

This system uses hydraulic pressure created by a pump connected to the engine to assist with steering. The pump pushes hydraulic fluid into the steering gear, reducing the effort needed to turn the wheel. - Electric Steering Systems

Modern systems utilize an electric motor powered by the vehicle’s battery to provide steering assistance. The motor adjusts the assistance based on driver input and road conditions, ensuring responsive and efficient performance.

Efficiency and Power Loss

- Hydraulic Power Steering

These systems often experience energy loss since the pump runs continuously, even when minimal assistance is needed. This can reduce efficiency, particularly during low-speed driving or when the engine is heavily loaded. - Electric Steering Systems

These systems minimize energy waste by drawing power only when steering assistance is required. This improves fuel efficiency and reduces overall energy consumption, making it a more economical choice.

Components and Reliability

- Hydraulic Power Steering

It relies on components like pumps, hydraulic lines, and steering gears, which are prone to wear and leaks over time. Regular maintenance is essential to ensure smooth operation. - Electric Steering Systems

These systems use electric motors, sensors, and control units, which are generally more reliable and require less upkeep. Advanced technologies, like resolvers for angle detection, provide precise steering performance in varying conditions.

Advantages of Electric Power Steering

- Improved Fuel Efficiency: EPS systems consume energy only when steering assistance is needed, reducing overall energy usage compared to traditional hydraulic systems.

- Lower Engine Load: Without a hydraulic pump, EPS reduces strain on the engine, improving fuel economy and minimizing harmful emissions.

- Streamlined Design: The compact and lightweight structure of EPS systems allows for greater design flexibility during vehicle manufacturing, optimizing space and efficiency.

- Adjustable Steering Assistance: Manufacturers can easily customize EPS power assistance through software, tailoring steering characteristics to suit various vehicles or driving conditions.

Applications of Electric Power Steering in Modern Vehicles

- Enhanced Handling and Stability: EPS adjusts power assistance based on speed, offering easier handling at low speeds and improved stability at high speeds.

- Better Driver Experience: With customizable steering assistance, EPS delivers a tailored steering feel, enhancing comfort and overall driver satisfaction.

- Seamless System Integration: EPS integrates seamlessly with advanced driver-assistance systems like lane-keeping assist and automatic emergency braking, improving vehicle safety.

- Positive Environmental Impact: By optimizing energy use and lowering emissions, EPS helps create a more fuel-efficient and environmentally friendly driving experience.

Common Issues with Electric Power Steering and How to Fix Them

Load Alleviation and Steering Assistance

Problem: Drivers may face heavy steering loads, especially when the vehicle body tilts.

Solution: EPS applies assistive forces using an electric motor to reduce the load. By estimating steering angle deviations from wheel speeds, the system dynamically adjusts the assist force for smoother steering.

Fault Diagnosis and Circuit Reliability

Problem: EPS systems may fail to diagnose issues in the circuit supplying power to the motor, causing inconsistent power assist control.

Solution: Some EPS devices monitor motor operation during specific vehicle states, diagnosing faults when no driving currents are detected. This ensures consistent performance and reliability.

Impact Load Management

Problem: Impact loads can disrupt EPS operation, potentially leading to system failure.

Solution: Advanced EPS systems are designed to continue driving the motor unless the failure is critical. This ensures uninterrupted assist, even under impact conditions.

Discomfort in Steering

Problem: Steering discomfort may arise before and after applying driving force.

Solution: EPS minimizes this by using multiple electric motors to apply force directly to the steering column, pinion gear, or rack gear. This design enhances comfort and responsiveness.

Wobbling and Steering Load Reduction

Problem: Steering failures can cause wobbling and increase steering load.

Solution: EPS systems detect torque sensor failures, estimate the steering angle, and increase assist force to reduce the driver’s effort, improving control and stability.

Downsizing and Weight Reduction

Problem: Traditional EPS systems can be bulky and heavy, impacting vehicle efficiency.

Solution: Modern EPS designs focus on reducing size and weight by optimizing motor configurations, speed reducers, and housing materials.

Ambient Temperature Estimation and Current Limiting

Problem: High ambient temperatures can affect EPS performance, requiring additional temperature sensors.

Solution: Advanced systems estimate temperature based on vehicle speed and limit motor current as needed, eliminating the need for extra sensors while maintaining efficiency.

Power Supply Abnormalities

Problem: EPS systems may stop functioning entirely if the power supply becomes unstable.

Solution: Advanced EPS systems detect power abnormalities and temporarily pause assist control, resuming operation once the supply stabilizes. This ensures system reliability during power fluctuations.

Future Trends in Electric Power Steering Technology

Advancements in System Efficiency

Energy Savings and Enhanced Control: Manufacturers are focusing on energy-efficient designs, especially in the electronic control of hydraulic systems. These improvements optimize energy consumption while maintaining excellent steering performance.

High-Reliability Systems: Modern EPS systems now utilize DSP control and PWM techniques. These technologies precisely adjust power current, ensuring consistent and reliable steering assistance.

Integration of Advanced Control Strategies

Control Algorithms and Torque Optimization: Advanced strategies, such as PID control and return algorithms, are increasingly used to improve torque reduction and steering return ability. These enhancements ensure better stability and responsiveness across diverse driving conditions.

Enhanced Sensor Integration: The integration of sensors like yaw rate and vehicle speed sensors is becoming more common. These sensors refine self-aligning torque calculations, enabling smoother steering and increased vehicle safety.

Adoption of Innovative Materials and Technologies

Silicon Carbide (SiC) Technology: SiC technology is revolutionizing EPS systems with its superior switching frequencies, lower energy losses, and better thermal performance. This innovation improves efficiency, reduces size, and boosts power density for enhanced system performance.

Market Trends and Application Expansion

Global Shift to Electric Systems: The automotive industry is rapidly transitioning from hydraulic to electric systems, especially in passenger cars and SUVs. This trend is driven by the demand for cost-effective and high-performance solutions, particularly in emerging markets.

Popularity of Column-EPS Technology: Column-EPS is gaining traction for its cost-efficiency and reliable steering assistance. Its adaptability makes it a preferred choice for various vehicle types, balancing performance and affordability.

Conclusion: Why Electric Power Steering Is the Future of Driving

Electric Power Steering (EPS) combines efficiency, safety, and adaptability, making it the ideal choice for modern vehicles. By enhancing fuel efficiency, integrating seamlessly with advanced safety features, and delivering a customizable driving experience, EPS is shaping the future of driving. As automotive technology evolves, EPS stands out as a key innovation for performance, reliability, and sustainability.

To get detailed scientific explanations of Electric Power Steering, try Patsnap Eureka.