Technical Background and Objectives

Background

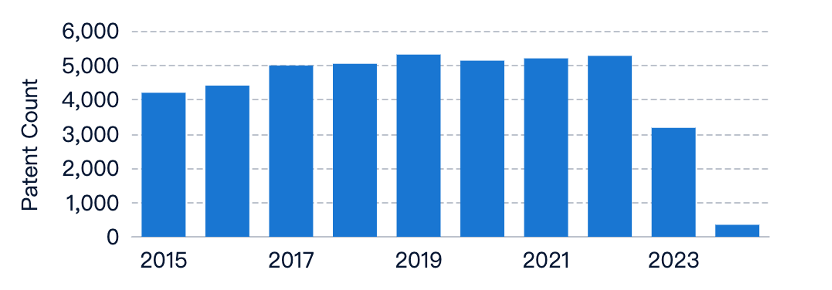

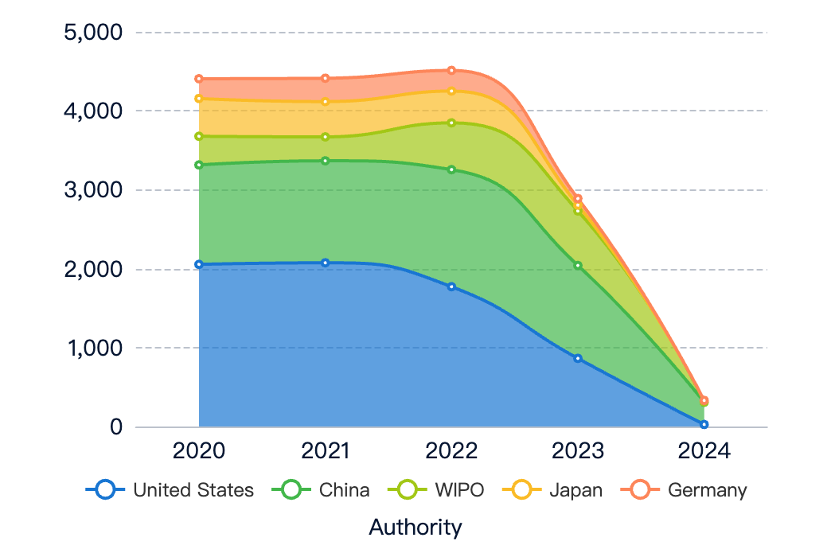

The technical field of ‘engine brake reduce volume’ has shown a consistent increase in patent applications, indicating sustained innovation and research efforts. This trend suggests significant industry interest in reducing the volume of engine brakes. In contrast, literature publications initially rose but have plateaued in recent years, implying a shift towards applied research and commercialization.

Objectives

The primary objective is to explore and develop innovative solutions to reduce the volume of engine brakes, enhancing the driving experience and mitigating noise pollution. By addressing this issue, the research aims to maintain safety and efficiency while minimizing the acoustic impact on the environment.

To get a detailed scientific explanations of Engine Brake Noise, try Eureka.

Technical Current Status Analysis

Engine Brakes

Engine brakes, also known as compression release engine brakes or Jake brakes, are auxiliary braking systems used primarily in heavy-duty vehicles. They work by temporarily opening the exhaust valves near the end of the compression stroke, releasing compressed air and creating a braking effect.

Applications and Impact:

- Trucking Industry: Reduces wear on service brakes, prevents overheating, and extends brake life.

- Bus Industry: Essential for safe operation in mountainous regions or urban areas with frequent stops and starts.

- Noise Pollution: Reducing engine brake noise is crucial for compliance with noise regulations and improving the driving experience.

Technical Characteristics and Challenges:

- Exhaust System Design: Optimizing exhaust system to dampen noise.

- Valve Timing and Lift: Precise control of exhaust valves to reduce noise.

- Cylinder Deactivation Strategies: Using a subset of cylinders for braking to reduce noise.

- Noise Insulation and Dampening: Improving materials to reduce noise transmission.

- Engine Design and Combustion Characteristics: Fundamental design adjustments to reduce noise.

- Integration with Other Braking Systems: Coordinating with exhaust brakes or retarders for optimal performance.

Technological Paths:

- Advanced Exhaust System Design: Incorporate advanced mufflers, resonators, and noise-canceling technologies.

- Intelligent Valve Control Systems: Implement advanced control systems for precise valve regulation.

- Active Noise Cancellation (ANC) Technologies: Integrate ANC systems to counteract engine brake noise.

- Cylinder Deactivation and Control Strategies: Optimize strategies for selective cylinder engagement.

- Noise Insulation and Dampening Materials: Use advanced materials in critical areas to reduce noise.

- Engine Design Optimization: Adjust engine parameters to inherently reduce noise.

- Integrated Braking System Control: Seamlessly coordinate engine brakes with other systems.

Research Content

Research Objectives

The primary objective is to explore and develop innovative solutions to reduce the volume of engine brakes, enhancing the overall driving experience and mitigating noise pollution. The goal is to balance safety and efficiency while minimizing the acoustic impact.

Research Direction and Focus

Noise Reduction Mechanisms

- Study sound propagation and noise generation within engine brakes.

- Explore active noise control, passive noise insulation, and vibration damping.

Material Selection and Design Optimization

- Identify materials with superior acoustic properties.

- Use computational simulations and experimental testing to optimize component design.

Integration and Testing

- Integrate promising noise reduction strategies into prototype systems.

- Conduct extensive testing and validation in controlled environments and real-world conditions.

Cost-Benefit Analysis and Commercialization

- Assess economic viability, manufacturing costs, material availability, and market demand.

- Explore strategies for commercialization, including collaborations, IP protection, and regulatory compliance.

Technical Development Roadmap

Key Areas of Advancement

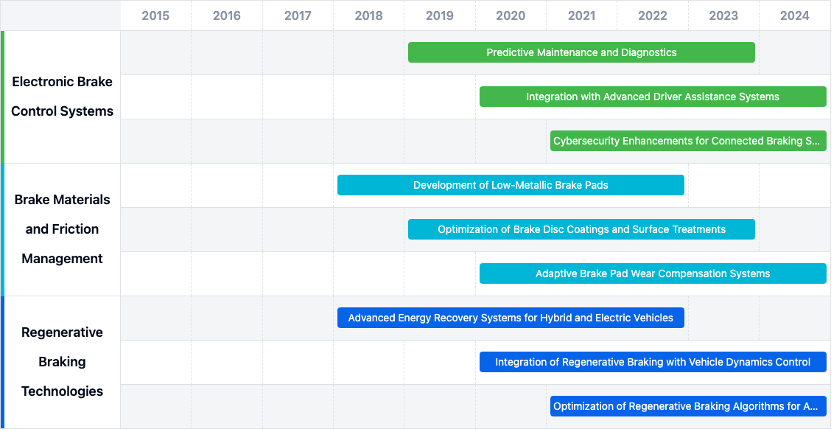

- Electronic Brake Control Systems: Predictive maintenance, diagnostics, and integration with advanced driver assistance systems.

- Brake Materials and Friction Management: Development of low-metallic brake pads, optimization of brake disc coatings, and adaptive brake pad wear compensation systems.

- Regenerative Braking Technologies: Advanced energy recovery systems, integration with vehicle dynamics control, and optimization for autonomous driving.

These advancements aim to enhance safety, efficiency, and connectivity while promoting sustainability and technological innovation in braking systems.

Main Player Analysis

Key Players and Focus

- Beijing University of Technology: Focus on experimental studies related to engine brake volume reduction, including variable valve timing and alternative fuels.

- Toyota Motor Corp.: Extensive patents in advanced fuel injection systems, combustion chamber designs, and engine control strategies.

- Anna University: Research on alternative fuels, fuel additives, and nanoparticle blends in diesel engines.

- Ford Global Technologies LLC: Patents related to engine design, combustion chamber geometries, and exhaust system optimizations.

- Robert Bosch GmbH: Patents in fuel injection systems, engine control units, and exhaust aftertreatment technologies.

Current Technical Solution Overview

Compression Release Engine Brake

Mechanism: Utilizes the compression release mechanism to reduce compression pressure in cylinders during the compression stroke.

Noise Reduction: Techniques to reduce noise include optimizing valve timing, using mufflers, and incorporating resonators.

Control Systems: Advanced control systems regulate operation based on vehicle speed, engine load, and driver input.

Integration: Integration with other braking systems like exhaust brakes for comprehensive braking solutions.

Engine Brake Noise Reduction

Design Modifications: Changes to brake components to reduce noise.

Exhaust System Design: Use of mufflers, resonators, and noise-canceling components.

Engine Enclosures and Covers: Sound insulation to reduce noise propagation.

Engine Intake System Design: Optimization to reduce noise generated during braking.

Engine Brake Control Systems

Control Systems: Systems to optimize performance and noise reduction.

Variable Control: Adjusting braking force based on various factors.

Integration with Other Braking Systems: Coordinated braking performance leveraging different systems.

Noise Reduction: Techniques like adjusting valve timing and incorporating noise-canceling technologies.

Integrated Engine Brake Configurations

Configurations: Efficient and compact engine braking mechanisms.

Noise Reduction: Techniques to reduce noise during operation.

Control Systems: Electronic control units, sensors, and algorithms.

Combined Systems: Integration of engine brakes and exhaust brakes.

Actuation Systems: Hydraulic or pneumatic mechanisms for precise control.

Engine Brake Systems for Specific Applications

Exhaust Noise Reduction: Systems to reduce noise during engine braking.

Variable Control Systems: Adjustable braking force based on driving conditions.

Integrated Brake Systems: Coordinated braking action with vehicle’s conventional brakes.

Specific Vehicle Types: Tailored systems for heavy-duty trucks, buses, or off-road vehicles.

Energy Recovery: Systems to recover energy during engine braking.

Key Patent Interpretation

Patent Highlights

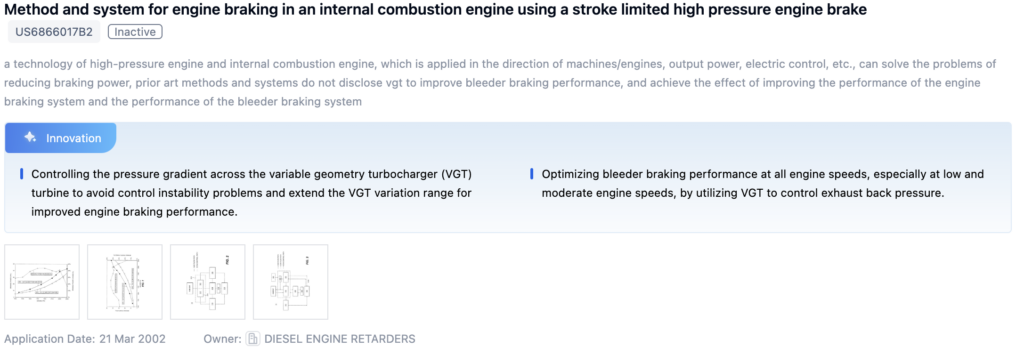

Patent 1: Method and System for Engine Braking

- Controlling the pressure gradient across the variable geometry turbocharger (VGT) turbine to avoid control instability problems and improve engine braking performance.

- Optimizing bleeder braking performance at all engine speeds using VGT to control exhaust back pressure.

Patent 2: Method and System for Engine Braking

- Utilizing VGT in a bleeder braking system to increase intake and exhaust manifold pressures, improving performance.

- Recognizing the advantage of bleeder brakes in requiring lower force for valve actuation and generating less noise.

Patent 3: Apparatus for Controlling Engine Brake Force

- Determining desired vehicle speed based on actual speed when the accelerator pedal is released.

- Controlling engine intake air quantity to maintain desired speed, limiting intake air to reference value based on transmission speed ratio.

Possible Research Directions

- Compression Release Engine Brake Systems: Utilize the engine’s compression to create braking force by releasing compressed air during the compression stroke.

- Engine Brake Control Strategies: Optimize performance and noise reduction through timing, duration, and intensity adjustments.

- Integrated Engine Brake Configurations: Combine different braking mechanisms for enhanced performance.

- Noise Reduction Techniques for Engine Brakes: Use baffles, mufflers, and sound-dampening components integrated into the exhaust system or engine compartment.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!