Sustainability Goals for Borosilicate Glass

Borosilicate glass, known for its thermal and chemical resistance, is widely used in various industries, including laboratory equipment, cookware, and specialized optics. Enhancing its sustainability involves optimizing manufacturing processes, exploring alternative materials, and promoting responsible end-of-life management. Key objectives include:

- Reducing Energy Consumption: Implement energy-efficient furnaces, heat recovery systems, and integrate renewable energy sources.

- Using Alternative Raw Materials: Substitute traditional components with recycled glass cullet or industrial by-products.

- Extending Product Lifespan: Design durable products, implement recycling programs, and raise awareness about proper waste management.

- Collaboration: Work with manufacturers, researchers, and regulatory bodies to establish industry standards and guidelines.

To get a detailed scientific explanations of borosilicate glass, try Eureka.

Market Demand for Sustainable Glass Applications

The market demand for sustainable borosilicate glass is rising due to environmental awareness and regulatory pressures:

- Circular Economy: Industries like pharmaceuticals, food and beverage, and laboratory equipment seek resource-efficient solutions.

- Renewable Energy: High-performance glass materials are needed for solar panels and concentrated solar power systems.

- Consumer Goods: Eco-friendly packaging solutions and reusable glass containers are in demand.

- Laboratory Practices: Sustainable borosilicate glass equipment is essential for reducing waste in laboratories.

Current State and Challenges in Borosilicate Glass

Challenges include:

- High Energy Consumption: Production requires high temperatures, contributing to greenhouse gas emissions.

- Raw Material Scarcity: Limited availability of boron and its environmental impact.

- Recycling Difficulties: Unique composition complicates recycling.

- Geographical Variability: Regional factors affect access to raw materials and recycling infrastructure.

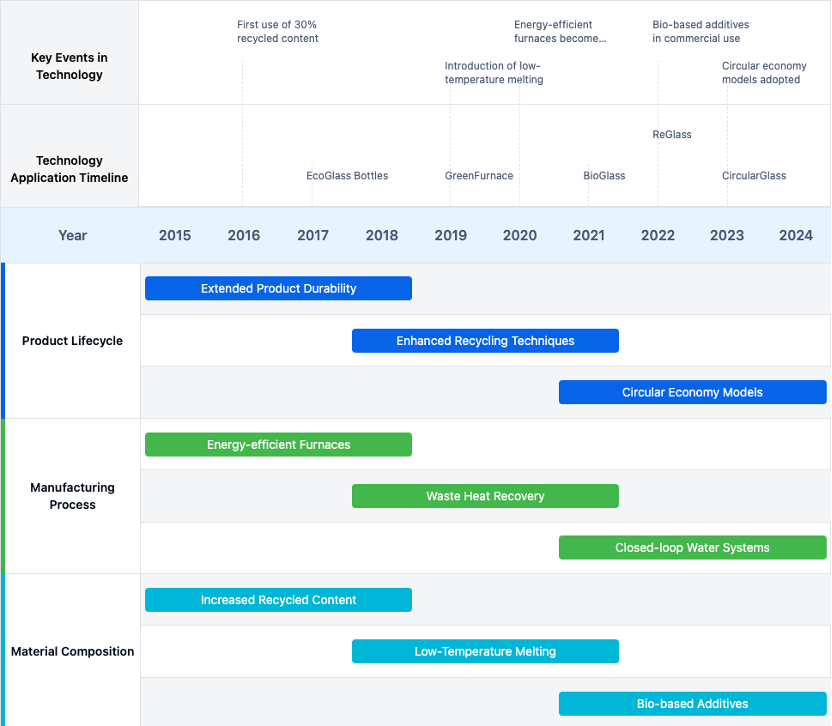

Evolution of Borosilicate Glass Technologies

Existing Solutions for Sustainable Glass Production

Borosilicate Glass Composition and Properties

- Enhanced Chemical Resistance: Specific ratios of boron oxide, silica, and other components.

- Optical Applications: Tailored compositions for lenses and solar cell covers.

- Low Thermal Expansion: Suitable for cookware and laboratory equipment.

- Biomedical Applications: Biocompatibility and mechanical properties for medical devices.

- Eco-Friendly Compositions: Incorporate recycled materials and reduce energy requirements.

Preparation and Manufacturing of Borosilicate Glass

- Methods: Melting, forming, and annealing techniques.

- Specialized Products: Tailored for medical, pharmaceutical, and heat-resistant applications.

- Sustainable Manufacturing: Use recycled materials, reduce energy consumption, and minimize waste.

Applications

- Solar Devices: High chemical durability and UV resistance.

- Pharmaceutical Containers: High chemical resistance and inertness.

- Optical Elements: High transparency and low thermal expansion.

- Chemically Strengthened Glass: Enhanced mechanical properties.

Recycling and Waste Treatment

- Recycling Methods: Processing waste glass for new products.

- Waste Gas and Liquid Treatment: Capturing and processing waste streams.

- Waste from Etching Processes: Treating and recycling waste liquids and sludge.

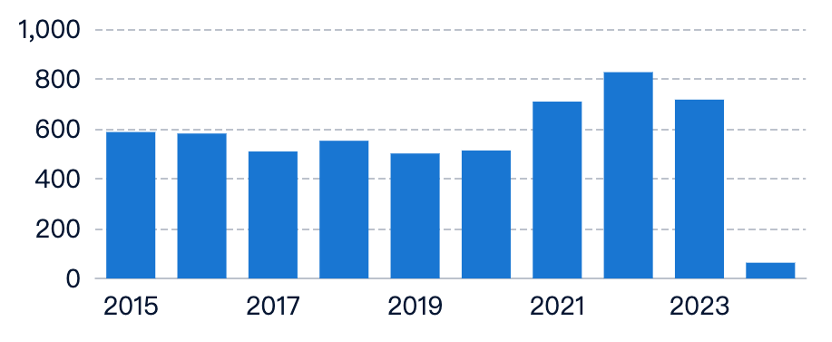

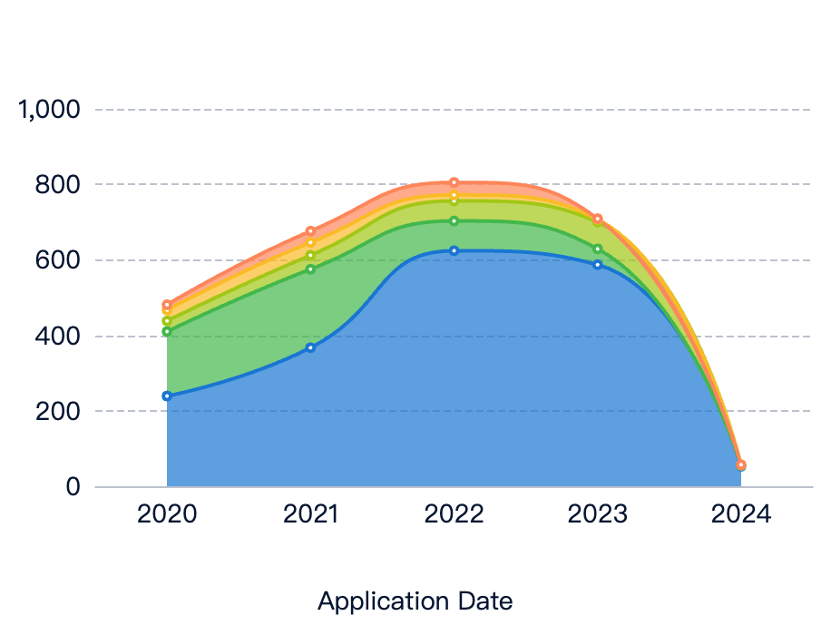

Key Players in Borosilicate Glass Industry

Semiconductor Energy Laboratory Co. Ltd.

- Patents: 226 patents on sustainability.

- Focus: Alternative raw materials and energy-efficient processes.

Corning Inc.

- Patents: 180 patents on sustainability.

- Focus: Recycling, alternative materials, and reducing environmental impact.

AGC Inc. (Japan)

- Patents: 266 patents on sustainability.

- Focus: Raw material alternatives, energy efficiency, and new applications.

Applied Mechanics Corp.

- Research: Recycled glass mixtures and new phosphate glasses for construction.

Bhabha Atomic Research Centre

- Research: Immobilization of high-level nuclear waste using borosilicate glass.

Core Innovations in Borosilicate Glass Sustainability

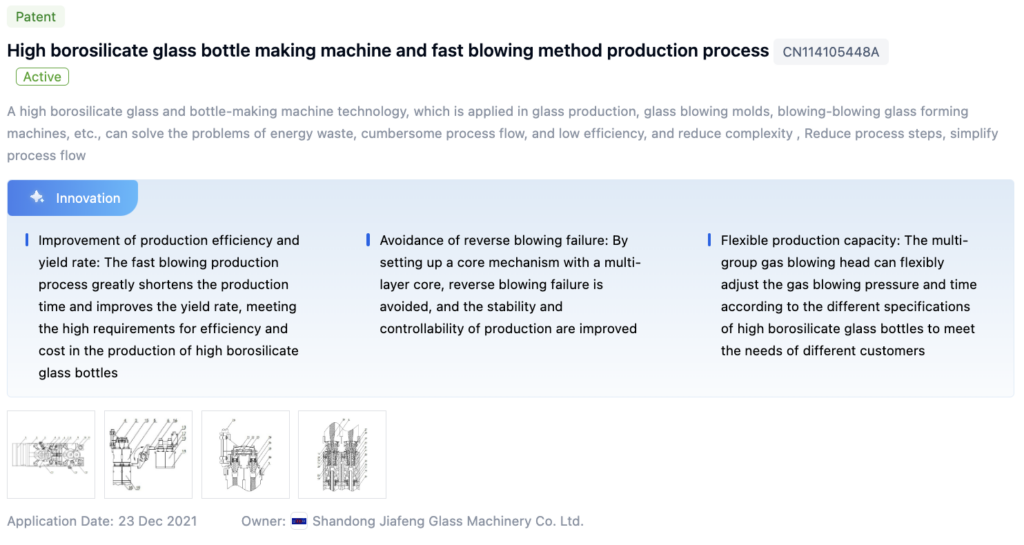

Patent 1: High Borosilicate Glass Bottle Making Machine and Fast Blowing Method

- Core Points:

- Efficiency: Fast blowing process improves yield and reduces complexity.

- Stability: Multi-layer core prevents reverse blowing failure.

- Flexibility: Adjustable gas blowing pressure and time for different specifications.

Patent 2: White Jade Color High Borosilicate Glass

- Core Points:

- Composition: Silicon dioxide, boron, aluminum oxide, sodium chloride, and coloring agents.

- Appearance: White jade-like color with excellent refractive index.

- Stability: Optimized coloring agent ratio enhances phase separation.

Paper 1: Potential Use of Borosilicate Glass to Make Neutron Shielding Mortar

- Core Points:

- Pozzolanic Material: Controls alkali-silica reaction and provides neutron shielding.

- Strength Development: Enhances compressive strength.

Potential Breakthroughs in Sustainable Glass

- Improved Chemical Resistance: Adjusting boron oxide, silica, and other components.

- Solar Energy Applications: High transparency and thermal stability.

- Sustainable Production: Utilizing waste materials, reducing energy consumption.

- Pharmaceutical and Medical Applications: High chemical resistance and biocompatibility.

Environmental Impact of Borosilicate Glass

Manufacturing Impact:

- High Energy Consumption: High-temperature processes.

- Greenhouse Gas Emissions: CO2 emissions from fuel combustion.

- Waste Generation: Solid waste, air emissions, and wastewater.

- Water Consumption: Significant use in production.

Mitigation Strategies:

- Energy Efficiency: Improve processes and use renewable sources.

- Recycling Technologies: Promote circular economy.

- Regulations: Strict guidelines for handling, transportation, and disposal.

Regulatory Landscape for Sustainable Glass

Key Regulations:

- Waste Framework Directive (EU): Sets targets for waste reduction and recycling.

- Extended Producer Responsibility (EPR): Manufacturers responsible for product lifecycle.

- Restriction of Hazardous Substances (RoHS): Limits toxic substances in manufacturing.

- Energy Efficiency and Emissions: Regulations for adopting energy-efficient processes.

Compliance:

- Industry Standards: Recycled content, energy efficiency, and responsible sourcing.

- Importance: Minimize environmental impact and promote sustainable practices.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!