OLED Display Evolution

OLED display technology has experienced remarkable growth since its beginnings, evolving through multiple stages marked by breakthroughs in performance, efficiency, and usability. The journey began in the late 1980s with the creation of the first organic electroluminescent devices. These early developments laid the groundwork for what would become a game-changing display technology.

Whether you’re curious about OLED display architecture, material efficiency, or failure mechanisms, Eureka Technical Q&A offers expert-led explanations that simplify complex display technologies—helping engineers, developers, and tech enthusiasts stay ahead in innovation.

Throughout the 1990s, researchers concentrated on improving the efficiency and durability of OLED materials. Their efforts paid off in 1997, when Pioneer launched the first commercial OLED display in a car stereo system. This marked the transition from lab-based prototypes to real-world applications.

The early 2000s brought rapid advancements, as major players like Kodak and Samsung invested heavily in OLED research and production. This era saw a shift from passive-matrix OLEDs (PMOLED) to active-matrix OLEDs (AMOLED), significantly boosting image quality and energy efficiency. These improvements helped OLED displays gain traction in consumer electronics.

By the mid-2000s, OLEDs began appearing in portable devices. Sony introduced the world’s first OLED TV in 2007, showcasing the potential of OLED in home entertainment. Around the same time, Samsung’s Galaxy smartphones helped push AMOLED displays into the mainstream. Meanwhile, LG focused on developing large-format OLED panels for TVs, launching its first OLED television in 2013.

As the technology matured, the industry explored new applications. Flexible and transparent OLED displays emerged, unlocking possibilities for foldable phones, curved screens, and futuristic product designs. At the same time, improvements in manufacturing processes led to better yields and lower costs, making OLED more accessible for a wider range of products.

In 2022, the introduction of quantum dot OLED (QD-OLED) displays marked a new chapter. By combining OLED with quantum dot technology, manufacturers achieved even greater color accuracy and brightness, enhancing the viewing experience.

Looking ahead, OLED innovation is set to continue. Researchers are focused on extending the lifetime of blue OLED materials, improving energy efficiency, and creating new display formats like rollable and stretchable screens. Efforts are also underway to develop printable OLEDs and integrate materials such as perovskites, which could open the door to even more advanced display solutions.

The evolution of OLED displays is far from over. With ongoing research and strong market demand, OLED technology remains at the forefront of the next generation of displays across consumer electronics, automotive systems, and beyond.

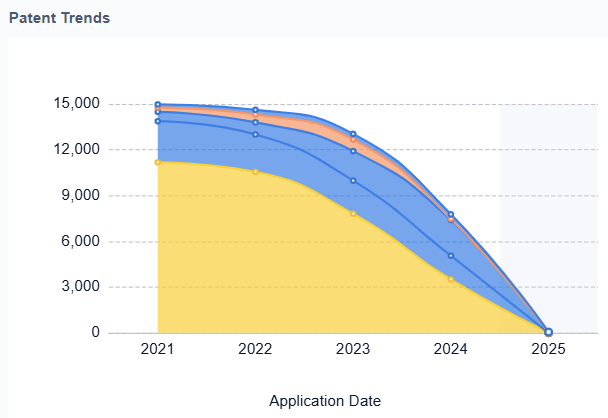

OLED Market Analysis

The OLED display market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in smartphones, televisions, and other electronic devices. As of 2023, analysts value the global OLED market at approximately $38 billion and project it to grow at a compound annual growth rate (CAGR) of around 13% through 2028. Strong demand for OLED technology continues to drive this growth, thanks to its superior contrast ratios, wider viewing angles, and faster response times compared to traditional LCD displays.

The smartphone segment currently dominates the OLED market, accounting for over 60% of total revenue. Major manufacturers like Samsung, Apple, and Huawei have increasingly adopted OLED displays in their flagship devices, driving demand and technological advancements. The television sector is also showing promising growth, with OLED TVs gaining popularity among consumers seeking premium viewing experiences. Additionally, emerging applications in automotive displays, wearable devices, and augmented reality (AR) headsets are expected to create new opportunities for OLED technology.

Geographically, Asia-Pacific leads the OLED market, with South Korea and China being the primary manufacturing hubs. However, increasing investments in OLED production facilities in Europe and North America are likely to diversify the market landscape in the coming years. Key players such as Samsung Display, LG Display, BOE Technology, and Japan Display Inc. drive intense competition in the market. These companies continuously invest in research and development to enhance OLED performance and lower production costs.

Despite the positive outlook, several challenges persist in the OLED market. High manufacturing costs, particularly for larger displays, remain a significant barrier to widespread adoption in certain segments. Additionally, concerns about OLED lifespan and potential screen burn-in issues continue to impact consumer perception and market growth in some areas. However, ongoing technological advancements and economies of scale are expected to address these challenges over time.

Looking ahead, innovators will drive the OLED market’s expansion by advancing foldable and rollable displays, transparent OLEDs, and micro-LED hybrid technologies. The increasing focus on energy efficiency and sustainability is also likely to boost OLED adoption, as these displays generally consume less power than their LCD counterparts. As the technology matures and manufacturers lower production costs, OLED displays will enter new market segments and applications, further strengthening their role in the global display industry.

OLED Tech Challenges

OLED displays have made significant strides in recent years, but they still face several technical challenges that hinder their widespread adoption and performance optimization. One of the primary issues is the limited lifespan of organic materials, particularly blue emitters, which tend to degrade faster than their red and green counterparts. This differential degradation leads to color shift over time, affecting the display’s overall quality and longevity. Additionally, the susceptibility of OLED materials to moisture and oxygen poses a significant challenge, necessitating complex encapsulation techniques to protect the organic layers from environmental factors.

Another major hurdle is the efficiency of light extraction from OLED devices. A substantial portion of the light generated within the organic layers gets trapped due to total internal reflection, which reduces the display’s overall luminous efficacy. This issue affects top-emitting OLEDs in particular, making it a critical challenge for applications like mobile devices. The development of advanced optical outcoupling structures and materials is an ongoing area of research to address this limitation.

Manufacturing scalability remains a significant challenge, especially for large-area OLED displays. The current vapor deposition processes used for OLED production are complex and costly, making it difficult to achieve high yields and cost-effectiveness in large-scale manufacturing. This is particularly problematic for the production of large OLED TVs and potential applications in lighting.

Power consumption is another area of concern, especially for mobile devices where battery life is critical. While OLEDs are generally more energy-efficient than LCDs for displaying dark content, they can consume more power when displaying bright, white images. Improving the overall power efficiency of OLED displays across various content types is an ongoing challenge.

The phenomenon of image retention or burn-in, where static images can leave a persistent ghost image on the screen, continues to be a concern for OLED technology. While improvements have been made, completely eliminating this issue remains a challenge, particularly for displays used in applications with static elements like computer monitors or automotive displays.

Lastly, the development of flexible and foldable OLED displays presents its own set of challenges. While the organic nature of OLEDs makes them inherently suitable for flexible applications, creating durable, repeatedly foldable displays without compromising performance or lifespan is a complex task. Issues such as the development of flexible encapsulation materials, robust transparent electrodes, and mechanically stable organic layers are at the forefront of research in this area.

Addressing these technical challenges is crucial for the continued advancement and widespread adoption of OLED display technology across various applications, from smartphones and televisions to emerging fields like wearable devices and automotive displays.

OLED Milestones

OLED Industry Leaders

The OLED display market is in a growth phase, with increasing adoption across various industries. The global OLED market size is projected to expand significantly in the coming years, driven by demand for high-quality displays in smartphones, TVs, and emerging applications. Technologically, OLED displays are maturing, with major players like Samsung Display, BOE Technology, and LG Display leading innovation. Companies such as Sharp, TCL, and Tianma Microelectronics are also making strides in OLED technology development. The competitive landscape is intensifying as more manufacturers enter the market, focusing on improving efficiency, lifespan, and production costs of OLED displays. Future perspectives include advancements in flexible and transparent OLED technologies, as well as the integration of OLED with other emerging display technologies.

BOE Technology Group Co., Ltd.

BOE Technology Group Co., Ltd.

Technical Solution

BOE has been rapidly expanding its presence in the OLED market, particularly in small and medium-sized displays for smartphones and wearables. They have heavily invested in flexible OLED technology and developed screens that bend, fold, and roll. BOE recently introduced a 360-degree foldable OLED display that folds both inwards and outwards without showing a visible crease. They are also working on improving OLED efficiency and lifespan through the use of advanced materials and manufacturing processes, such as TADF (Thermally Activated Delayed Fluorescence) emitters.

Strengths: Rapid growth in OLED production capacity, innovative flexible display designs.

Weaknesses: Still catching up to market leaders in terms of quality and yield rates.

TCL China Star Optoelectronics Technology Co., Ltd.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution

TCL CSOT has been making significant strides in OLED technology, focusing on both small and large-sized displays. They have developed a proprietary inkjet-printed OLED technology, which offers potential cost savings and improved efficiency compared to traditional vapor deposition methods. TCL CSOT has also been working on rollable OLED displays, demonstrating a 17-inch printed OLED that can be rolled into a tube with a diameter of just 4mm. In addition, they are exploring the integration of OLED technology with other emerging display technologies, such as micro-LED, to create hybrid solutions that leverage the strengths of both.

Strengths: Innovative inkjet-printed OLED technology, diverse product range from small to large displays. Weaknesses: Relatively new entrant in the OLED market, still building brand recognition.

Samsung Display Co., Ltd.

Samsung Display Co., Ltd.

Technical Solution

Samsung Display has been at the forefront of OLED technology, particularly in the mobile display market. Their latest innovation is the development of QD-OLED (Quantum Dot OLED) technology, which combines the benefits of QLED and OLED. This hybrid technology uses blue OLED as a light source and quantum dots to convert some of the blue light into red and green, resulting in improved color accuracy, brightness, and energy efficiency. Samsung has also made significant progress in foldable OLED displays, showcasing their ability to produce flexible, durable screens for smartphones and tablets.

Strengths: Market leader in mobile OLED displays, advanced QD-OLED technology, expertise in foldable displays.

Weaknesses: High production costs, potential for screen burn-in in static image areas.

Tianma Microelectronics Co., Ltd.

Tianma Microelectronics Co., Ltd.

Technical Solution

Tianma has been focusing on developing OLED displays for various applications, including smartphones, automotive, and industrial use. They have made significant progress in flexible OLED technology, showcasing displays with under-screen cameras and sensors. Tianma’s latest innovation is their “Transparent OLED” technology, which allows for the creation of see-through displays with high transparency and color reproduction. They are also working on improving the energy efficiency of OLED displays through the development of new pixel structures and driving methods.

Strengths: Diverse application focus, innovative transparent OLED technology.

Weaknesses: Smaller production capacity compared to industry leaders, less experience in large-sized OLED panels.

Koninklijke Philips NV

Koninklijke Philips NV

Technical Solution

While Philips has divested much of its display business, the company continues to engage in OLED technology through its lighting division and research partnerships. Philips actively explores OLED lighting applications and develops thin, flexible OLED panels for integration into various surfaces and products. They have also been researching ways to improve OLED efficiency and lifespan, particularly focusing on the development of new materials and manufacturing processes. Philips’ work in OLED lighting could potentially have applications in display technology as well, particularly in areas such as automotive and architectural displays.

Strengths: Expertise in OLED lighting applications, strong research and development capabilities. Weaknesses: Limited direct involvement in OLED display

Current OLED Solutions

OLED display structure and materials

OLED displays utilize organic light-emitting materials to produce light. The structure typically includes multiple layers such as electrodes, emission layers, and transport layers. Advanced materials and configurations are employed to enhance efficiency, color accuracy, and longevity of the display.

- OLED display structure

OLED displays consist of multiple layers, including a substrate, electrodes, organic layers, and encapsulation. The structure typically includes an anode, hole transport layer, emissive layer, electron transport layer, and cathode. Various materials and configurations are used to optimize performance, efficiency, and durability. - OLED materials and emitters

OLED displays utilize various organic and inorganic materials for different layers. Emissive materials include small molecules and polymers, with phosphorescent and thermally activated delayed fluorescence (TADF) emitters gaining popularity. Host materials, transport materials, and injection materials are carefully selected to enhance device performance and color purity. - Flexible and foldable OLED displays

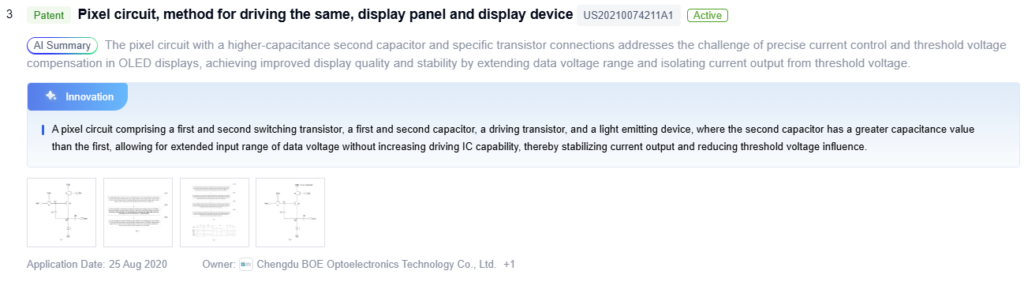

Advanced OLED technologies enable the creation of flexible and foldable displays. These displays use specialized substrates, encapsulation methods, and structural designs to achieve flexibility while maintaining performance. Innovations in materials and manufacturing processes contribute to the development of bendable and rollable OLED screens. - OLED display driving and control

OLED displays employ various driving schemes and control mechanisms to ensure uniform brightness, color accuracy, and longevity. This includes pixel circuits, thin-film transistors (TFTs), and compensation techniques to address issues such as threshold voltage shifts and current variations in the organic layers.

Flexible and foldable OLED displays

Innovations in flexible OLED technology allow for the creation of bendable, foldable, and rollable displays. These advancements involve specialized substrates, encapsulation methods, and stress-resistant materials to maintain display performance while enabling new form factors and applications.Expand

OLED display driving and control methods

Advanced driving schemes and control methods are developed to improve OLED display performance. These include pixel compensation techniques, power management strategies, and refresh rate optimization to enhance image quality, reduce power consumption, and extend display lifespan.Expand

OLED display integration with other technologies

OLED displays are integrated with various technologies to enhance functionality. This includes incorporating touch sensors, biometric sensors, and cameras under the display, as well as combining OLED technology with other display types for hybrid solutions.Expand

OLED manufacturing processes and yield improvement

Advancements in manufacturing processes aim to improve OLED display production efficiency and yield. This involves innovations in deposition techniques, patterning methods, and quality control measures to enhance uniformity, reduce defects, and lower production costs.

OLED Innovations

Future OLED Directions

Flexible and foldable OLED displays mark a major advancement in modern display technology. By using organic materials that allow bending and folding without losing visual performance, these displays offer exciting new possibilities for how we design and interact with digital devices.

The core innovation lies in the ability of OLEDs to function without the need for a rigid backlight. Instead, they emit light from each pixel, making them ideal for use on bendable and rollable surfaces. Several critical technological breakthroughs have made flexible OLEDs viable.

First, flexible substrates are used in place of traditional glass. Materials like polyimide and ultra-thin glass allow the display to bend while still protecting against moisture and oxygen—two elements that can damage organic layers. This shift was key to enabling truly bendable screens.

Second, thin-film encapsulation (TFE) plays a vital role in shielding OLED components from environmental exposure. These ultra-thin barrier layers are designed to flex without cracking, ensuring long-term durability of the organic materials inside.

Third, traditional electrodes made from indium tin oxide (ITO) don’t hold up well under bending. Engineers have replaced them with flexible alternatives such as silver nanowires, conductive polymers, and graphene-based materials. These options maintain conductivity even under stress.

Another key innovation is neutral plane design. This engineering technique places the most sensitive OLED layers near the axis that experiences the least stress when bent. It minimizes mechanical strain and helps prevent damage to critical components during repeated use.

For foldable displays, mechanical design is equally important. Manufacturers have developed advanced hinge systems that allow folding while protecting the screen. These hinges are engineered to minimize visible creases and extend the life of the display.

These advancements have opened the door to a wide range of new products. Foldable smartphones, rollable TVs, and wearable displays are just the beginning. In automotive design, flexible OLEDs allow for curved dashboards and seamless, futuristic user interfaces.

Looking ahead, the focus will shift to improving durability and increasing the number of folding cycles a display can handle. Researchers are also exploring more extreme designs, such as stretchable displays that can expand and contract without losing functionality. At the same time, scaling up production and reducing costs will be critical for bringing flexible OLEDs into the mass market.

Strengths of this technology include the ability to create entirely new device shapes, enhance user experience with adaptable screens, and support space-saving designs across industries. These benefits make flexible OLEDs highly appealing for future innovation.

However, challenges remain. Production costs are still higher than those of traditional displays. Long-term durability, especially for foldable devices, needs improvement. Achieving consistent image quality on curved or bent surfaces is another technical hurdle. Manufacturing and quality control also become more complex with flexible components.

Despite these challenges, the future of flexible and foldable OLEDs looks promising. As the technology matures, it is likely to reshape how we use screens in everyday life—from smartphones and wearables to cars and home entertainment systems.

OLED Manufacturing

OLED manufacturing has seen rapid progress in recent years, driven by the growing demand for high-quality displays across consumer electronics, automotive, and industrial sectors. The production process involves several key stages, including substrate preparation, thin-film deposition, patterning, encapsulation, and final module assembly. Among these, the deposition of organic materials is one of the most critical and technically demanding steps.

Two main deposition techniques dominate the industry: thermal evaporation and solution processing. Thermal evaporation, also known as vacuum deposition, is widely used for manufacturing small-molecule OLEDs. In this process, organic compounds are heated in a vacuum chamber until they vaporize, then condense onto the substrate. This method offers excellent precision and layer uniformity but comes with higher costs and limitations in scaling for large-area production.

Solution processing is emerging as a cost-effective alternative, especially for polymer-based OLEDs. This method involves dissolving organic materials in a solvent and applying them to the substrate using techniques such as inkjet printing or spin coating. While solution processing promises lower production costs and better scalability for large displays, it still faces challenges in achieving the same performance and lifespan as thermally evaporated OLEDs.

One of the ongoing hurdles in OLED manufacturing is improving yield rates and reducing overall production costs. To tackle these issues, manufacturers are optimizing workflows, adopting new equipment, and transitioning to larger substrate sizes like Gen 8.5 and beyond. These advancements help increase throughput and lower per-unit production costs, particularly for larger panels used in TVs and monitors.

The rise of flexible and foldable OLED displays has also reshaped manufacturing strategies. Producing these next-generation displays requires new materials such as ultra-thin glass and plastic substrates. At the same time, manufacturers must develop advanced encapsulation technologies to protect the delicate organic layers from moisture and oxygen, which can degrade performance over time.

Looking forward, the future of OLED manufacturing will likely center on boosting efficiency, minimizing waste, and expanding the range of display applications. Emerging solutions such as printed OLEDs and solution-processed QD-OLEDs could simplify production while enabling new design possibilities. These technologies offer a path toward lower-cost, high-performance displays that are easier to manufacture at scale.

Sustainability is also becoming a priority in OLED production. As environmental concerns grow, manufacturers are exploring greener materials and more eco-friendly processes. Reducing solvent use, recycling materials, and improving energy efficiency in production lines will be essential steps in creating a more sustainable OLED industry.

In summary, OLED manufacturing continues to evolve rapidly, with advances in materials, techniques, and design flexibility driving the next generation of displays. By improving efficiency and embracing sustainable practices, the industry is well-positioned to meet future market demands while expanding into new and innovative applications.

OLED Sustainability

OLED displays have made notable progress in sustainability, with growing efforts to reduce environmental impact and improve resource efficiency. As demand for energy-efficient and eco-friendly electronics rises, OLED technology continues to evolve to meet these expectations.

One of the main areas of improvement is energy efficiency. OLED panels now consume less power during both active use and standby mode. This reduction in energy demand extends battery life in mobile devices and lowers electricity usage in larger displays. These improvements contribute directly to reducing the carbon footprint of OLED-equipped products.

Another key development is the reduced reliance on rare earth elements and scarce materials. Manufacturers are actively researching alternatives and refining production techniques to use fewer resources. By minimizing material waste and improving supply chain sustainability, the industry is moving toward greener manufacturing standards.

OLED sustainability also benefits from increased device longevity. Newer panels last longer and resist common issues like burn-in and color fading. By extending the lifespan of displays, users replace devices less often, which helps lower electronic waste and supports a more sustainable product cycle.

Looking ahead, several promising innovations are shaping the future of OLED sustainability. One area of focus is recyclability. Researchers are exploring materials and designs that make OLED displays easier to disassemble and recycle. The use of bio-based or biodegradable components in non-electronic layers could also reduce environmental impact at the end of a product’s life.

Another exciting direction involves energy harvesting. Future OLEDs may integrate solar cells or ambient light-harvesting technology to supplement or even replace traditional power sources. These features could lead to semi or fully self-sustaining displays, further enhancing their eco-friendly appeal.

Sustainability efforts also extend to the manufacturing process. Emerging methods like solution-processed OLEDs promise lower energy use and reduced material waste. Additionally, manufacturers are beginning to adopt AI and machine learning to optimize production efficiency, reduce defects, and minimize resource consumption.

As OLED technology continues to advance, the focus on environmental responsibility will become even stronger. Future innovations may include repairable and modular OLED designs that extend product life, as well as advanced recycling systems capable of recovering valuable materials. These developments align with broader global goals to promote a circular economy and reduce electronic waste.

In summary, OLED sustainability is improving across all stages of the product lifecycle—from energy use and materials to manufacturing and end-of-life recovery. With continued innovation, OLED displays are poised to play a key role in creating a more sustainable future for consumer electronics.

To get detailed scientific explanations of OLED Display, try Patsnap Eureka.