High Impact Polystyrene (HIPS) is a tough, versatile thermoplastic widely used in consumer products, packaging, and electronics. It is created by blending polystyrene with rubber (typically polybutadiene) to improve impact resistance.

In this blog, we’ll explore the material’s structure, grades, applications, and advantages. We’ll also highlight how innovation—powered by PatSnap Eureka AI Agent—is accelerating development in sustainable HIPS and advanced composites.

What is High Impact Polystyrene?

HIPS is a rubber-modified version of polystyrene designed for durability and impact resistance. While general-purpose polystyrene is brittle, HIPS offers a more rugged profile suitable for structural applications.

- Chemical Name: High Impact Polystyrene

- Structure: Polystyrene matrix with dispersed rubber domains

- Key Traits: Tough, machinable, opaque, printable, and low-cost

Composition & Properties / Performance

| Property | Typical Value |

|---|---|

| Molecular Formula | (C8H8)n with polybutadiene domains |

| CAS Number | 9003-55-8 |

| Density | ~1.04 g/cm³ |

| Melt Flow Index | 2–10 g/10 min |

| Glass Transition Temp | ~100°C |

| Tensile Strength | 18–30 MPa |

| Elongation at Break | 40–60% |

| Impact Resistance | High |

| Surface Quality | Excellent for printing and bonding |

Key Performance Highlights:

- Printable and paintable

- Easily thermoformed or injection molded

- Good dimensional stability and machinability

Material Grades & Designations

It comes in many grades, tailored to different end-uses:

| Grade Name | Feature | Use Case |

|---|---|---|

| HIPS GP | General-purpose | Disposable trays, toys |

| HIPS FR | Flame-retardant | Electronics housings |

| HIPS Food-Grade | FDA-compliant | Yogurt cups, meat packaging |

| HIPS ESCR | Chemical-resistant | Cosmetic containers |

| HIPS Print Grade | Enhanced surface finish | Signage, 3D printing |

Standards:

- ASTM D1238 (Melt Flow Rate)

- ISO 306 (Heat Deflection Temperature)

- UL 94 (Flammability classification)

Application Landscape

HIPS is favored for both its performance and affordability across many industries:

1. Packaging Industry

- Use: Clamshell packaging, food containers, cups, and lids.

- Benefits: Low-cost, food-safe grades, easy to thermoform.

2. Consumer Goods

- Use: Toys, appliance parts, and storage units.

- Benefits: Safe, lightweight, and tough. Printable for branding.

3. Electronics & Electrical

- Use: TV and monitor housings, switches, battery casings.

- Benefits: Flame-retardant grades resist electrical hazards.

4. 3D Printing

- Use: Support structures and matte finish prints.

- Benefits: Easily dissolvable in limonene, perfect for dual extrusion.

5. Signage & Displays

- Use: Indoor advertising boards, point-of-sale displays.

- Benefits: Printable surface, dimensional stability, bright white finish.

HIPS vs Other Similar Materials

| Property | HIPS | ABS | GPPS |

|---|---|---|---|

| Impact Strength | High | High | Low |

| Cost | Low | Medium | Low |

| Surface Printability | Excellent | Moderate | Moderate |

| Transparency | Opaque | Opaque | Transparent |

| Ease of Processing | Very Easy | Moderate | Easy |

Advantages of High Impact Polystyrene (HIPS)

- Great Impact Resistance: Suitable for robust applications

- Excellent Printability: Ideal for advertising, branding, or labeling

- Cost-Effective: Among the lowest-cost engineering plastics

- Ease of Processing: Molds quickly at low temperatures

- Compatible with Solvent Welding & Painting

- Good Chemical Resistance: Against mild acids and bases

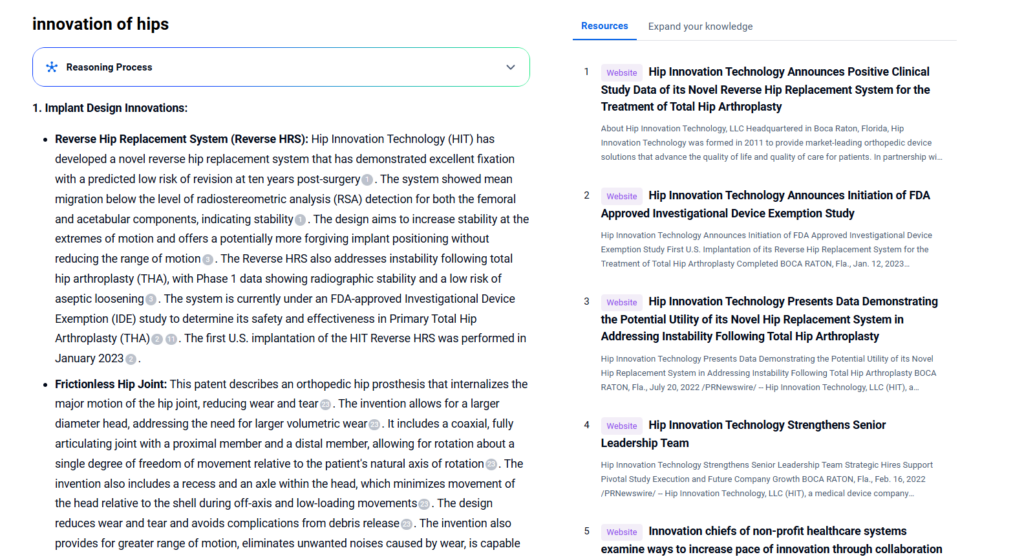

Innovations & Technology

Innovation in High Impact Polystyrene is advancing across multiple fronts—from sustainability to performance enhancement. These developments aim to improve impact strength, reduce environmental impact, and meet next-gen manufacturing demands.

1. Nano-Reinforced HIPS Composites

- What’s New: Researchers are incorporating nanoclays, graphene oxide, and carbon nanotubes (CNTs) into HIPS.

- Purpose: Improve mechanical strength, flame resistance, and electrical conductivity.

- Outcome: Enhanced its grades with:

- ~30% higher tensile strength

- Improved heat deflection temperature

- Antistatic or conductive capabilities for ESD-sensitive applications

- Applications: Electronics packaging, battery casings, and structural parts.

2. Bio-Based and Eco-Modified HIPS

- Innovation Drivers: Regulatory push (REACH, EPR policies), demand for low-carbon materials.

- Solutions:

- Partial substitution of polystyrene with renewable monomers like polylactic acid (PLA) or starch-derived polyols.

- Use of post-consumer recycled (PCR) HIPS in rigid packaging and signage.

- Example Patent Trend: Increasing patents for blends of HIPS and biodegradable polyesters (e.g., PCL, PBAT).

- Challenge & Progress: Maintaining impact resistance and processability while increasing bio-content.

3. Smart Additive Systems

- Advanced Additives: Flame-retardants based on halogen-free phosphorus compounds, expandable graphite, and intumescent systems.

- Other Functional Additives:

- UV stabilizers for outdoor signage.

- Antimicrobial agents for hygiene packaging or medical device housings.

- Impact: HIPS is becoming safer and more functional in sensitive environments.

4. HIPS in Multi-Material 3D Printing

- Support Material: HIPS is dissolvable in limonene, making it ideal for use with ABS or PLA in dual-extrusion 3D printing.

- Recent Breakthroughs:

- Modified HIPS filaments with improved dimensional stability.

- Low-odor, fast-dissolving grades for consumer desktop printers.

- Trend Insight: Surge in patents on 3D printable HIPS blends with tuned flow and interlayer adhesion properties.

5. Processability & Tooling Innovation

- Injection Molding Improvements:

- Use of low-viscosity HIPS for thin-walled, complex geometry parts.

- Development of quick-cooling mold inserts to reduce cycle times.

- Extrusion Tech:

- Foamed HIPS sheets for lightweight packaging and insulation.

- Co-extruded multilayer sheets with HIPS as core/substrate layer for cost and performance balance.

6. Digital Twin and Simulation Integration

- AI & Simulation Tools: Adoption of digital twin models to simulate its behavior under thermal/mechanical stress.

- Software Integration:

- Moldflow analysis for HIPS parts.

- Life-cycle simulation to estimate recyclability and material degradation over time.

Sustainability & Environmental Impact

- Recyclability: 100% recyclable (RIC Code #6), though not always curbside.

- Eco Trend: Growth in recycled and bio-filled HIPS demand.

- Lifecycle Impact: Long lifespan reduces need for frequent replacement.

- Compliance: Many HIPS grades comply with FDA, RoHS, and REACH.

Note: Some regions restrict polystyrene usage due to environmental concerns. Regulations may encourage biodegradable alternatives or recycling mandates.

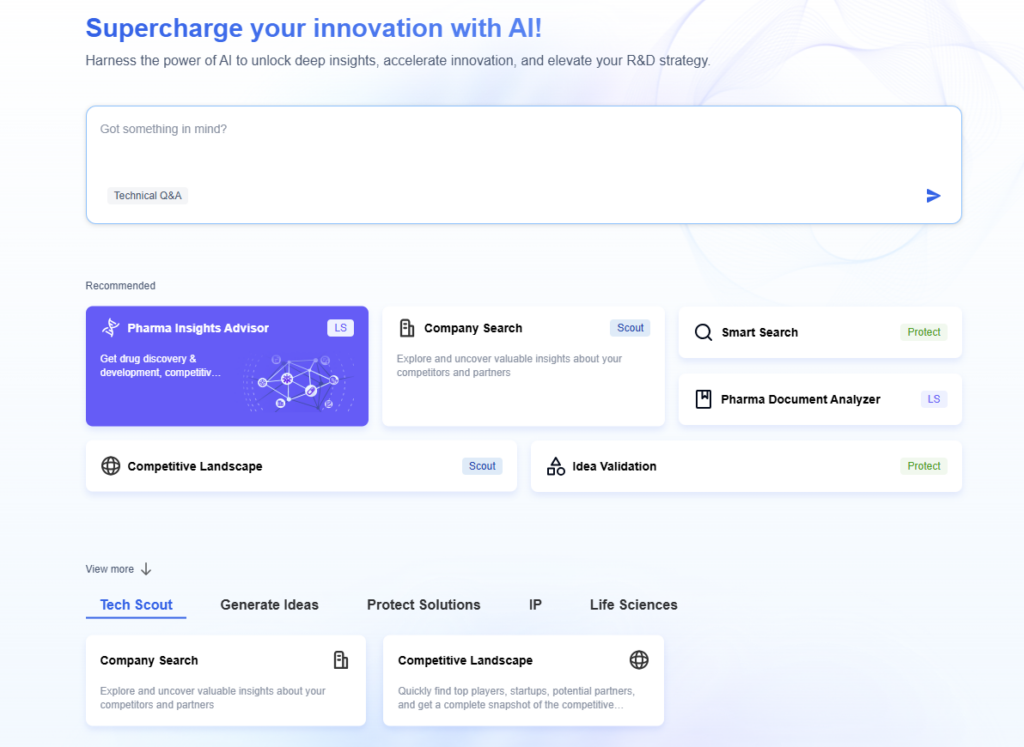

PatSnap Eureka AI Agent Capabilities

With PatSnap Eureka AI Agent, you can:

- Explore Global Patents on HIPS formulations, applications, and processing

- Analyze Competitor Trends in packaging, 3D printing, and electronics

- Identify Material Substitution Opportunities (e.g., HIPS vs PLA or rPET)

- Track Regulatory Risk and green certification developments

- Visualize Innovation Density via smart dashboards for IP and R&D leaders

Conclusion

High Impact Polystyrene is a reliable, affordable, and versatile material powering everything from food containers to high-performance 3D prints. Its ease of processing, strength, and printable surface make it a staple in countless industries.

As sustainability concerns grow, innovations in recycled HIPS, bio-based fillers, and dual-material printing are ensuring this classic plastic stays relevant in the future. Tools like PatSnap Eureka AI Agent are critical in unlocking HIPS’s evolving potential through real-time patent intelligence and competitive insight.

FAQs

Yes, food-grade it is FDA compliant and used in yogurt cups and trays.

Yes, it is recyclable but may not be accepted in all municipal recycling programs.

Yes, especially for dissolvable support structures and matte finish parts.

It is cheaper, easier to process, and better for print applications, while ABS offers higher thermal resistance.

Eureka identifies formulation trends, competitor activity, and regulatory updates to guide strategic development.

For more scientific explanations of HIPS , try PatSnap Eureka AI Agent.