What Is a Vernier Caliper?

The Vernier caliper is a highly precise measuring tool designed to determine the size or distance of objects with remarkable accuracy. It plays a critical role in fields like mechanical engineering, manufacturing, and quality control, where precise measurements are essential.This versatile instrument features a main scale, a sliding vernier scale, and dual jaws for securely gripping objects. Its unique design enables users to achieve precise readings by aligning the markings on the main and vernier scales. Whether you’re measuring internal, external, or depth dimensions, the Vernier caliper is a go-to tool for accurate results.In this article, we’ll explore how Vernier calipers work, their key components, and why they remain indispensable in precision measurement.

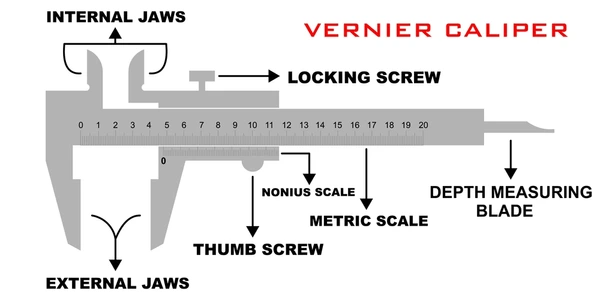

Parts of a Vernier Caliper Explained

- Main Scale: The main scale forms the fixed part of the caliper, providing the primary measurement scale with graduated units, such as millimeters or inches.

- Vernier Scale: The vernier scale slides over the main scale, featuring calibrated markings that enable precise measurements beyond the main scale’s increments.

- Jaws: The caliper includes two jaws—one fixed to the main scale and one movable, connected to the vernier scale. These jaws open and close to grip the object being measured.

- Throat Depth: The throat depth measures the maximum distance between the jaws when fully opened, indicating the largest object the caliper can measure.

- Zero Mark: The zero mark on the main scale serves as a reference point for aligning the vernier scale and taking accurate measurements.

- Vernier Zero: The vernier zero aligns with the main scale to mark the starting point for measurements.

- Least Count: The least count defines the smallest measurement increment readable on the vernier scale, establishing the caliper’s precision.

How Vernier Calipers Work: The Principle of Precision Measurement

- Measurement Setup

To begin, position the caliper around the object to be measured. Ensure the jaws gently touch the opposite sides of the object for accurate placement. - Reading the Main Scale

Observe the main scale to get the coarse measurement. This value provides the larger unit of measurement, such as centimeters or millimeters. - Aligning the Vernier Scale

Next, slide the vernier scale along the main scale until the markings align perfectly. This alignment is key to obtaining precise results. - Reading the Vernier Scale

Examine the vernier scale to find the marking that aligns exactly with a marking on the main scale. This finer reading adds extra precision to the measurement. - Calculating the Total Measurement

Finally, combine the values from the main scale and the vernier scale. The sum of these readings gives you the complete and highly accurate measurement.

Applications of Vernier Calipers in Different Fields

Mechanical Processing and Manufacturing

In mechanical processing, vernier calipers ensure precise measurements of components, crucial for high-accuracy products. Innovations like multi-stage amplification structures now provide micron-level accuracy, enhancing their suitability for precision manufacturing.

Science Laboratories

Vernier calipers play a vital role in scientific research, enabling precise data collection in experiments. Their accuracy is indispensable in fields such as biology, chemistry, and physics, where exact measurements are essential for analysis.

Medical Applications

In healthcare, vernier calipers measure small medical instruments and devices with unmatched precision. This accuracy directly impacts the quality of medical equipment, ensuring reliable patient care and treatment outcomes.

Automotive Industry

The automotive sector uses vernier calipers to measure small parts and components critical to vehicle assembly. Accurate measurements ensure these parts meet stringent quality standards and function seamlessly.

Aerospace Industry

Aerospace applications demand extreme precision, making vernier calipers indispensable for measuring components with tight tolerances. Their accuracy is vital for maintaining the safety and performance of aircraft and spacecraft.

Educational Use

In education, vernier calipers teach students the principles of precise measurement. They are essential in physics and engineering labs, helping learners understand and apply accurate measurement techniques in practical scenarios.

Machine Shops

Machine shops rely on vernier calipers to measure parts during machining processes. This ensures that components meet required specifications and adhere to strict tolerances, maintaining high-quality outputs.

Steel Industry

In the steel industry, vernier calipers measure the dimensions of steel components with exceptional accuracy. Consistent and precise measurements are critical for ensuring the quality and reliability of steel products.

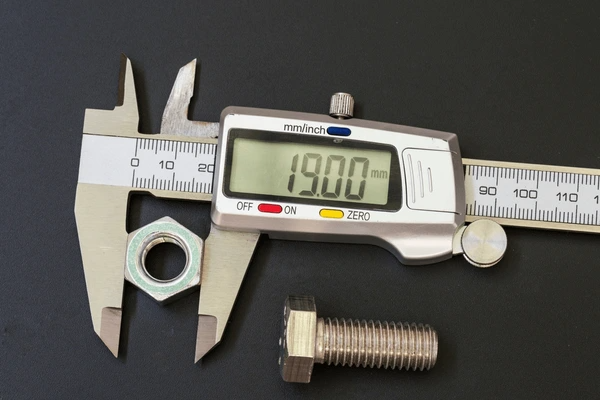

How to Use a Vernier Caliper: Step-by-Step Guide

Understand the Components

- Main Scale: Provides the base measurement in millimeters or inches.

- Slider: A movable part that adjusts for the object’s size.

- Jaws: Two sets of jaws—external jaws for outer dimensions and internal jaws for inner dimensions.

- Vernier Scale: Adds precision to the reading by measuring minute differences.

Prepare the Caliper

- Clean the caliper thoroughly to remove dust or debris.

- Check for any physical damage to ensure accurate readings.

- Familiarize yourself with the zero marks on both scales.

Zero the Caliper

- Close the jaws completely and check alignment.

- Confirm the zero on the vernier scale matches the zero on the main scale.

Position the Object

- For external measurements: Place the object between the external jaws and close them snugly.

- For internal measurements: Insert the internal jaws into the opening and expand them to touch both sides.

- For depth measurements: Use the depth rod by extending it into the object.

Take the Reading

- Main Scale: Note the reading just before the zero line of the vernier scale.

- Vernier Scale: Find the vernier mark that perfectly aligns with a mark on the main scale.

- Combine the main scale and vernier scale readings for the final measurement.

Record the Measurement

- Write down the measurement clearly.

- Take multiple readings if necessary to ensure consistency.

- Use the average of the readings for the most accurate result.

Calibrate and Maintain

- Periodically calibrate the caliper against a standard gauge.

- Store the caliper in a protective case to avoid damage.

- Keep the caliper clean and lubricate moving parts if required for smooth operation.

To get detailed scientific explanations of the Vernier caliper, try Patsnap Eureka.