Technical Background and Objectives of Rack and Pinion Steering

The rack and pinion steering system is integral to modern vehicles, converting the steering wheel’s rotational motion into the linear motion required to turn the wheels. Ensuring the stability and reliability of this system is crucial for vehicle safety and performance. The development of it has evolved significantly with the demand for improved steering precision, responsiveness, and durability.

The primary objective in enhancing the stability of these systems is to minimize the effects of vibrations, shocks, and external forces that could cause steering wheel kickback or loss of control. This involves optimizing the design and materials of components such as the rack, pinion, and tie rods to enhance strength, rigidity, and resistance to wear. Another key objective is reducing the potential for binding or sticking due to contamination, corrosion, or improper lubrication. High-quality materials, precise manufacturing tolerances, and effective sealing and lubrication systems are essential for smooth operation.

Additionally, integrating advanced technologies such as electronic power steering (EPS) and active steering control opens new avenues for improving steering stability and responsiveness. These systems can actively compensate for external forces, adjust steering ratios, and provide variable assistance based on driving conditions.

To get detailed scientific explanations of rack and pinion steering, try Patsnap Eureka TechResearch.

Market Demand Analysis for Rack and Pinion Steering

The demand for improved stability in rack and pinion steering systems is driven by several factors:

- Vehicle Safety: As vehicle safety standards rise, the stability and reliability of steering systems have become paramount. A stable steering system helps prevent accidents caused by sudden or unexpected steering behavior, particularly at high speeds or in challenging road conditions.

- Autonomous Driving: The trend toward autonomous and semi-autonomous driving technologies has heightened the need for stable and reliable steering systems. These systems must respond accurately and consistently to inputs from advanced driver assistance systems (ADAS) and autonomous driving features.

- Luxury and Performance Vehicles: In the luxury and high-performance vehicle market, precise handling and steering feel are highly valued. Consumers in this segment demand steering systems with exceptional stability and responsiveness.

- Electric Power Steering (EPS) Challenges: The increasing adoption of EPS systems, which replace traditional hydraulic systems, has introduced new challenges in maintaining steering stability. EPS systems rely on electronic control units and sensors, which can be susceptible to interference or calibration issues, potentially affecting stability.

Overall, the market demand for improved stability in rack and pinion steering systems is driven by safety concerns, the rise of autonomous driving technologies, and the pursuit of superior driving experiences in luxury and performance vehicles. Addressing these demands through technological advancements and innovative solutions is crucial for automotive manufacturers to remain competitive.

Current State and Challenges of Rack and Pinion Steering

Rack and pinion steering systems face several stability challenges that can compromise vehicle handling and safety:

Vibration and Harshness

These systems are susceptible to vibrations and harshness caused by uneven road surfaces, tire imbalances, or worn-out components. Such vibrations can lead to steering wheel oscillations, affecting driver control and comfort.

Friction and Wear

Over time, the constant sliding motion of rack and pinion components can increase friction and wear. This leads to higher steering effort, reduced responsiveness, and potential binding or sticking of the steering components.

Geometric Alignment Issues

Proper alignment is crucial for optimal performance and stability. Misalignments due to manufacturing tolerances, improper installation, or component deformation can lead to steering irregularities and increased wear.

Environmental Factors

Exposure to temperature extremes, moisture, and road salt can accelerate corrosion and material degradation, affecting the system’s stability and longevity.

Design Limitations

The inherent design of rack and pinion systems, such as the length of the rack and the distance between tie rod ends, can influence sensitivity to external forces and vibrations.

Integration with ADAS

As vehicles incorporate more advanced driver assistance features, the stability and precision of the steering system become even more critical. Integrating these systems while maintaining stability poses significant challenges.

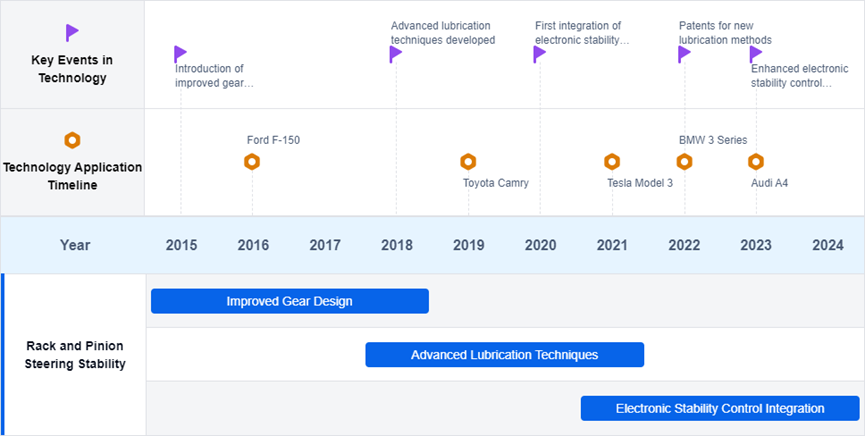

Technology Evolution Path of Rack and Pinion Steering

Current Technical Solutions

Gear Structure

The system typically consists of a rack connected to the steering wheel via a pinion gear. The rotation of the steering wheel causes the pinion gear to rotate, moving the rack laterally and transferring motion to the wheels.

Stability Enhancements

Ensuring stability involves using high-quality materials, precise gear meshing, and proper mounting and support. Incorporating damping mechanisms and optimizing steering geometry can reduce vibrations and improve overall stability.

Components and Design Considerations

Key components include the rack, pinion, tie rods, and steering knuckles. Design considerations involve selecting the appropriate gear ratio, materials, and lubrication systems, balancing steering effort, responsiveness, and feedback.

Maintenance and Repair

Regular maintenance, including inspections, lubrication, and component replacement, is essential for the longevity and safe operation of the steering system.

Key Players Analysis

Hyundai Mobis Co. Ltd.

Hyundai Mobis focuses on developing EPS systems that improve the stability of rack and pinion mechanisms. Their solutions include torque sensors and motor-driven actuators for enhanced control.

ZF Automotive Germany GmbH

ZF Automotive offers a range of steering systems, including rack and pinion designs with integrated stability control features. Their systems use advanced algorithms to enhance steering response and reduce vibrations.

Ford Global Technologies LLC

Ford Global Technologies has implemented adaptive steering technology in their vehicles, which adjusts the steering ratio based on vehicle speed and driving conditions, enhancing stability and maneuverability.

NSK Ltd.

NSK specializes in precision mechanical components and has developed advanced rack and pinion steering systems with improved stability features. Their systems incorporate high-precision gears and robust materials for enhanced durability.

Robert Bosch GmbH

Bosch has developed advanced EPS systems that enhance the stability and precision of rack and pinion steering systems. Their technology integrates sensors and actuators to provide real-time adjustments, improving vehicle handling and safety.

Key Technology Insights in Rack and Pinion Steering

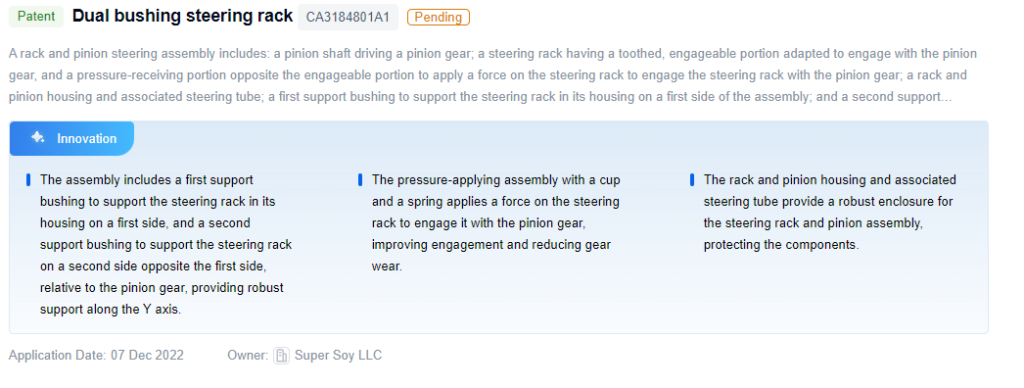

Patent 1: Dual Bushing Steering Rack

Key Points:

- The assembly includes a first support bushing to support the steering rack in its housing on one side and a second support bushing on the opposite side, providing robust support along the Y-axis.

- The pressure-applying assembly with a cup and a spring applies force to engage the steering rack with the pinion gear, improving engagement and reducing gear wear.

- The rack and pinion housing and steering tube provide a robust enclosure, protecting the components.

Patent 2: Augmented Rack And Pinion Steering System

Key Points:

- The use of a direct attachment between the rack and pinion gearset and the front solid axle eliminates the need for concerted motion between the draglink and suspension link, improving precision.

- The patent includes a slip-joint on the steering shaft to enhance the responsiveness of the steering system.

Paper 1: Design and Development of Rack and Pinion Steering Gear Assembly

Key Points:

- The work aimed to design a rack and pinion steering system for a passenger car by considering various parameters for effective directional response.

- 2D models were created to validate the kinematic algorithm, optimizing component dimensions and achieving a satisfactory Ackermann percentage.

- The steering system was designed and analyzed using CATIA CAD/CAE software.

Potential Innovation Directions

Rack and Pinion Steering with Improved Stability and Reduced Vibration

Various techniques are employed to enhance stability and reduce vibration. These include optimizing rack and pinion components, incorporating damping mechanisms, or utilizing specialized materials.

Variable Ratio Rack and Pinion Steering for Improved Handling

Some systems incorporate a variable ratio mechanism that adjusts the steering ratio based on vehicle speed or steering angle, improving handling and stability.

Enhanced Durability and Wear Resistance

To improve durability, design modifications and material selections are made, such as using specialized coatings or self-lubricating materials.

Improved Steering Feel and Feedback

Optimizing steering feel involves adjusting mechanical properties, incorporating specialized bearings or bushings, or integrating electronic control systems.

Regulatory and Compliance Factors

Regulatory and compliance factors are critical in ensuring the safety, reliability, and adherence to industry standards of rack and pinion steering systems. These systems must comply with regulations from bodies like the National Highway Traffic Safety Administration (NHTSA), the Society of Automotive Engineers (SAE), and the International Organization for Standardization (ISO). Compliance with environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive, is also essential.

Environmental Impact Considerations

Environmental considerations are crucial throughout the lifecycle of rack and pinion steering systems. Manufacturers must adopt environmentally friendly manufacturing practices, implement proper maintenance procedures, and develop effective recycling and disposal strategies. By considering the environmental impact from design to disposal, manufacturers can reduce the overall footprint of these systems.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!