Technical Background and Objectives

Improving the adsorption capacity of cabin air filters is a crucial objective in the automotive industry, as it directly impacts the air quality inside vehicles and the overall driving experience. The technical background of this objective can be traced back to the increasing concerns over air pollution and its adverse effects on human health, particularly in urban areas where vehicle emissions contribute significantly to poor air quality.

Over the years, various regulations and standards have been introduced to limit the emission of harmful pollutants from vehicles, including particulate matter (PM), nitrogen oxides (NOx), and volatile organic compounds (VOCs). However, even with stringent emission controls, the air inside vehicle cabins can still contain pollutants from external sources, such as traffic emissions, industrial activities, and natural sources like pollen and dust.

To address this issue, cabin air filters have become an essential component in modern vehicles, designed to remove airborne contaminants and improve the air quality inside the cabin. However, the adsorption capacity of these filters is limited, and they need to be replaced periodically to maintain their effectiveness. Improving the adsorption capacity of cabin air filters can extend their lifespan, reduce maintenance costs, and provide better protection against air pollutants for vehicle occupants.

The primary objective of this research is to explore innovative materials, designs, and technologies that can enhance the adsorption capacity of cabin air filters, while maintaining or improving their filtration efficiency and air flow characteristics. This may involve investigating new adsorbent materials with higher surface area and improved adsorption properties, optimizing filter media configurations, or incorporating advanced technologies such as electrostatic or photocatalytic processes.

Ultimately, the goal is to develop cabin air filters that can effectively remove a broader range of pollutants, including ultrafine particles, gaseous contaminants, and allergens, while ensuring a comfortable and healthy environment for vehicle occupants over an extended period of time.

Market Demand Analysis

The market demand for cabin air filters with improved adsorption capacity is driven by several factors. Firstly, there is a growing concern for air quality, particularly in urban areas where vehicle emissions and industrial pollution contribute to poor air quality. Cabin air filters play a crucial role in removing harmful particulates, gases, and odors from the air entering the vehicle’s cabin, ensuring a healthier and more comfortable environment for occupants.

Secondly, the increasing awareness of the health impacts of air pollution has led to stricter regulations and emission standards for vehicles. Automakers are under pressure to incorporate more effective air filtration systems to comply with these regulations and meet consumer expectations for cleaner air inside vehicles.

Furthermore, the rise in allergies and respiratory conditions has created a demand for cabin air filters that can effectively remove allergens, such as pollen, dust mites, and mold spores, from the air. Consumers with these conditions are willing to invest in high-performance air filters to alleviate their symptoms and improve their overall well-being while traveling.

Additionally, the growing popularity of electric and hybrid vehicles has created a need for cabin air filters that can effectively remove particulates and gases from the air, as these vehicles produce fewer emissions but still operate in polluted environments.

Market research indicates that the global cabin air filter market is expected to grow at a significant rate in the coming years, driven by the increasing demand for cleaner air in vehicles and stricter emission regulations. Consumers are becoming more aware of the importance of air quality and are willing to pay a premium for advanced air filtration systems that offer superior adsorption capacity and improved air quality.

In summary, the market demand for cabin air filters with improved adsorption capacity is fueled by concerns over air pollution, stricter emission regulations, the rise in allergies and respiratory conditions, and the growing popularity of electric and hybrid vehicles. Automakers and air filter manufacturers have a significant opportunity to capitalize on this demand by developing innovative solutions that address these market needs.

Current State and Challenges

The adsorption capacity of cabin air filters is a crucial aspect in ensuring clean and healthy air quality inside vehicles. Currently, the industry faces several challenges in improving this technology:

- Limited adsorption capacity: Existing cabin air filters have a limited capacity to adsorb various pollutants, particularly fine particulate matter (PM2.5) and gaseous contaminants like volatile organic compounds (VOCs) and nitrogen oxides (NOx). As emission standards become more stringent, there is a growing need for filters with higher adsorption efficiency and longer service life.

- Trade-off between adsorption capacity and airflow resistance: Increasing the adsorption capacity of filters often leads to higher airflow resistance, which can negatively impact the performance of the vehicle’s heating, ventilation, and air conditioning (HVAC) system. Finding the optimal balance between adsorption efficiency and airflow resistance remains a challenge.

- Limitations of traditional filter materials: Conventional filter materials, such as activated carbon and non-woven fabrics, have inherent limitations in terms of adsorption capacity, selectivity, and durability. There is a need for innovative filter media with improved adsorption properties and longer service life.

- Regeneration and disposal challenges: Many cabin air filters are designed for single-use, leading to frequent replacements and increased waste generation. Developing filters with regeneration capabilities or environmentally friendly disposal methods is a challenge that needs to be addressed.

- Geographical variations: The composition and concentration of air pollutants can vary significantly across different regions and climates. Designing filters that can effectively adsorb a wide range of pollutants under diverse environmental conditions is a complex task.

- Cost and manufacturing considerations: Improving the adsorption capacity of cabin air filters often requires the use of advanced materials and manufacturing processes, which can increase production costs. Striking a balance between performance and cost-effectiveness is a critical challenge for manufacturers.

Despite these challenges, ongoing research and development efforts are focused on exploring new filter media, optimizing filter designs, and developing innovative adsorption technologies to enhance the adsorption capacity of cabin air filters while addressing the associated trade-offs and limitations.

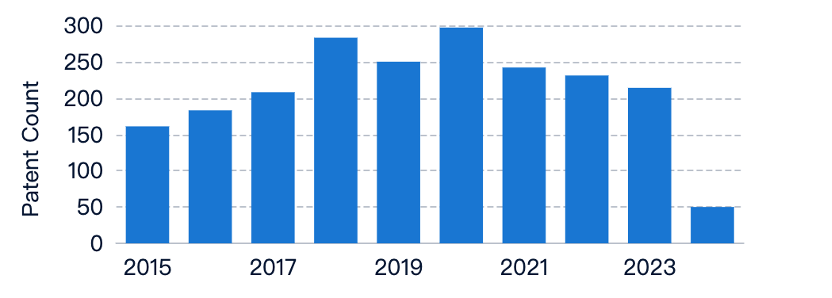

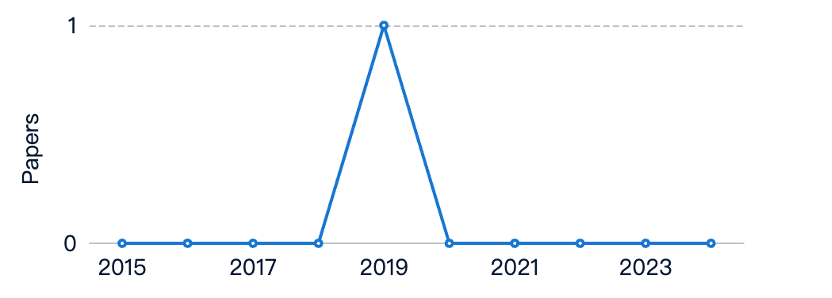

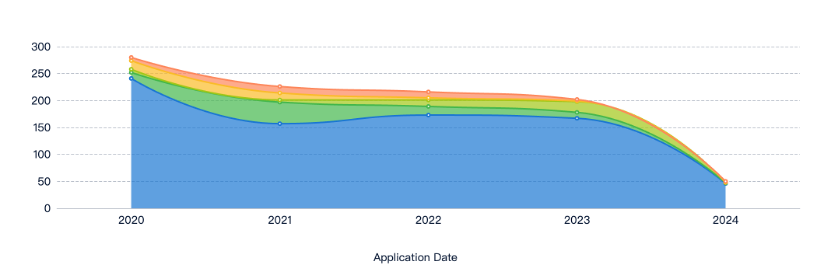

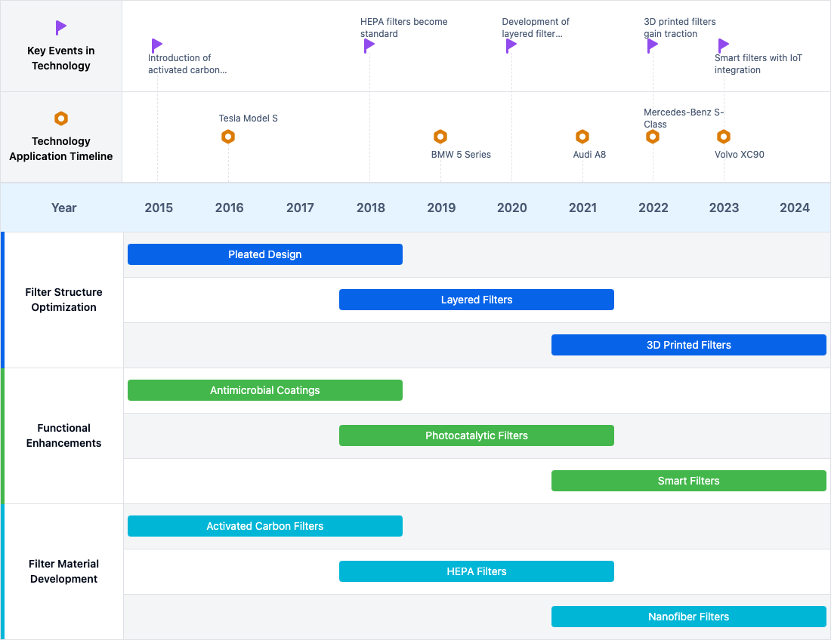

Technology Evolution Path

Current Technical Solutions

Cabin air filters with adsorption capabilities

These cabin air filters are designed to adsorb and remove various pollutants, gases, and odors from the air entering the vehicle cabin. They often incorporate materials like activated carbon, zeolites, or other adsorbents to enhance their adsorption capacity and improve air quality inside the cabin.

- Cabin air filters with adsorption capabilities for removing gaseous pollutants

- These cabin air filters incorporate adsorbent materials such as activated carbon or zeolites to remove gaseous pollutants like volatile organic compounds (VOCs), nitrogen oxides, and odors from the air entering the vehicle cabin. The adsorption capabilities enhance the air quality inside the cabin.

- Cabin air filters with high adsorption capacity for particulate matter

- These filters are designed with high adsorption capacity for capturing and retaining particulate matter such as dust, pollen, and other airborne particles, ensuring efficient filtration of the air entering the vehicle cabin. They may incorporate electrostatically charged fibers or specialized filter media.

- Cabin air filters with combined adsorption capabilities for gases and particulates

- These filters combine adsorption capabilities for both gaseous pollutants and particulate matter, offering comprehensive air purification for the vehicle cabin. They may incorporate multiple layers or a combination of adsorbent materials and filter media.

- Cabin air filters with adsorption capabilities and additional functionalities

- These filters not only offer adsorption capabilities but also incorporate additional features such as antimicrobial properties, photocatalytic oxidation, or deodorizing agents to further enhance the air quality inside the vehicle cabin.

Cabin air filters with high dust holding capacity

These filters are designed to have a high capacity for capturing and retaining particulate matter, such as dust, pollen, and other airborne particles. They often feature specialized filter media or structures that allow for efficient particle capture while maintaining low airflow resistance.

Cabin air filters with photocatalytic or UV treatment

These filters incorporate photocatalytic materials or UV light sources to enhance their air purification capabilities. The photocatalytic process or UV radiation can help break down and neutralize various pollutants, odors, and microorganisms present in the cabin air.

Cabin air filters with multi-functional or combined capabilities

These filters combine multiple air purification technologies, such as adsorption, particle filtration, and photocatalytic or UV treatment, to provide comprehensive air purification for the vehicle cabin. They aim to address various types of pollutants and contaminants simultaneously.

Cabin air filters with improved airflow or low resistance

These filters are designed to provide efficient air filtration while minimizing airflow resistance and pressure drop. They often feature optimized filter media structures or configurations to ensure adequate airflow and ventilation performance within the vehicle cabin.

Key Players Analysis

The competitive landscape for improving the adsorption capacity of cabin air filters is characterized by varying stages of industry development, market scale, and technology maturity. The industry is in a growth phase with increasing demand for advanced air filtration solutions driven by heightened awareness of air quality. The market scale is expanding, particularly in automotive and HVAC sectors. In terms of technology maturity, MANN+HUMMEL GmbH and Futaba Kogyo Co. Ltd. are leading with advanced research and development capabilities. Anhui Faxiou AUTOMOTIVE PARTS Co., Ltd. and Nippon Paper Industries Co., Ltd. are also significant players, focusing on innovative materials. enVerid Systems, Inc. is emerging with specialized solutions in air filtration technology.

MANN+HUMMEL GmbH

MANN+HUMMEL GmbH has developed advanced cabin air filters using nanofiber technology. These filters are designed to capture ultrafine particles, allergens, and harmful gases, significantly improving air quality inside the vehicle cabin. The nanofiber layer enhances the adsorption capacity, making the filters more effective in various environmental conditions.

Futaba Kogyo Co. Ltd.

Futaba Kogyo Co. Ltd. focuses on developing cabin air filters with activated carbon layers. These filters are designed to adsorb volatile organic compounds (VOCs) and odors, providing a cleaner and more pleasant cabin environment. The activated carbon layer enhances the filter’s adsorption capacity for gaseous pollutants.

Nippon Paper Industries Co., Ltd.

Nippon Paper Industries Co., Ltd. has introduced cabin air filters utilizing cellulose nanofibers. These filters offer high adsorption capacity for particulate matter and gaseous pollutants. The use of renewable cellulose nanofibers makes the filters environmentally friendly and sustainable.

enVerid Systems, Inc.

enVerid Systems, Inc. specializes in air filtration solutions that incorporate molecular filtration technology. Their cabin air filters are designed to capture and adsorb a wide range of pollutants, including particulate matter, VOCs, and other harmful gases. The molecular filtration technology enhances the overall adsorption capacity and efficiency.

Key Technology Interpretation

Patent1:Absorber and absorbent article

Paper 1:Preparation, characterization and kinetics study of chitosan/PVA electrospun nanofiber membranes for the adsorption of dye from water

Potential Innovation Directions

- Cabin air filters with enhanced adsorption capacity

- Cabin air filters with photocatalytic or antimicrobial properties

- Cabin air filters with high dust holding capacity

- Cabin air filters with integrated air purification systems

- Cabin air filters with improved airflow and low pressure drop

Regulatory and Environmental Considerations

Future Trends in Cabin Air Filtration

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!