Technical Background and Objectives

Improving the filtering effect of cabin air filters is a crucial aspect of ensuring a healthy and comfortable environment inside vehicles. The cabin air filter plays a vital role in removing pollutants, allergens, and other harmful particles from the air entering the vehicle’s cabin, thereby enhancing the air quality for occupants.

The development of cabin air filters has been driven by increasing concerns over air pollution, particularly in urban areas, and the need to protect vehicle occupants from exposure to harmful contaminants. Over the years, various advancements have been made in filter materials, design, and technology to improve their filtering efficiency and performance.

The primary objective of research in this field is to develop cabin air filters that can effectively capture a wide range of particulate matter, including fine particles (PM2.5), ultrafine particles, and even gaseous pollutants, while maintaining low airflow resistance and prolonged service life. Additionally, research efforts aim to enhance the filters’ ability to remove specific pollutants, such as volatile organic compounds (VOCs), ozone, and other harmful gases, which can have detrimental effects on human health.

Another important goal is to improve the filtering effect of cabin air filters, ensuring that they provide optimal performance while remaining affordable for widespread adoption in various vehicle segments. This involves exploring new materials, manufacturing processes, and design strategies that can enhance the filters’ performance while reducing production costs.

Furthermore, research in this area may also focus on developing smart or intelligent cabin air filtration systems that can adapt to changing environmental conditions or user preferences. These systems could potentially incorporate sensors and control mechanisms to adjust the filtration process based on real-time air quality data or user-defined settings, further improving the filtering effect of cabin air filters and user experience.

Market Demand Analysis

The market demand for cabin air filters is driven by several key factors. Firstly, the increasing awareness of air pollution and its detrimental effects on human health has led to a growing demand for effective air filtration solutions in vehicles. As people spend a significant amount of time in their cars, especially in urban areas with high levels of air pollution, the need for clean and fresh air inside the cabin has become a priority.

Secondly, the automotive industry’s focus on improving passenger comfort and well-being has further fueled the demand for advanced cabin air filters. Automakers are continuously seeking ways to enhance the overall driving experience, and providing a healthy and comfortable cabin environment is a crucial aspect of this endeavor.

Additionally, the rise of electric vehicles (EVs) and the increasing adoption of advanced driver assistance systems (ADAS) have created new challenges for cabin air filtration. EVs require specialized filters to remove particulates and odors that may be generated by the battery and electrical components, while ADAS sensors demand a clear and unobstructed view, necessitating efficient air filtration to prevent sensor obstruction.

Furthermore, the market demand for cabin air filters is influenced by regulatory standards and emissions norms. Many countries have implemented stringent regulations regarding vehicle emissions and air quality, driving the need for improving the filtering effect of cabin air filters systems in automobiles.

It is also worth noting that the demand for cabin air filters varies across different regions and markets. In densely populated urban areas with high levels of air pollution, the demand for advanced air filtration solutions is typically higher. Similarly, markets with a higher concentration of premium and luxury vehicles tend to have a greater demand for high-performance cabin air filters, as these vehicles often prioritize passenger comfort and air quality.

Overall, the market demand for cabin air filters is driven by factors such as air pollution concerns, passenger comfort and well-being, the rise of EVs and ADAS, regulatory standards, and regional variations in air quality and consumer preferences.

Current State and Challenges

The development of cabin air filters has seen significant progress in recent years, driven by the increasing demand for improved air quality and passenger comfort in vehicles. However, several challenges remain that hinder the achievement of optimal filtering performance.

One of the primary challenges is the trade-off between filtration efficiency and airflow resistance. While higher efficiency filters can effectively remove particulate matter and pollutants from the air, they often create higher resistance to airflow, leading to reduced ventilation and increased energy consumption. Finding the right balance between these two factors is crucial for ensuring both clean air and energy efficiency.

Another challenge lies in the diversity of contaminants present in the cabin air. Cabin air filters must be capable of removing a wide range of pollutants, including particulate matter (PM), volatile organic compounds (VOCs), nitrogen oxides (NOx), and even biological contaminants like pollen and bacteria. Developing filters that can effectively capture these diverse pollutants while maintaining high efficiency and low resistance remains a significant challenge.

Furthermore, the durability and longevity of cabin air filters are essential considerations. Filters need to maintain their performance over an extended period, withstanding various environmental conditions and exposure to contaminants. Ensuring consistent filtering efficiency throughout the filter’s lifespan is crucial for maintaining air quality and preventing premature replacement.

Geographical variations in air quality and pollution levels also pose challenges for cabin air filter development. Filters designed for urban areas with high levels of particulate matter may not perform optimally in regions with different pollution profiles or climatic conditions. Developing filters that can adapt to diverse environmental conditions is an ongoing challenge.

Additionally, the integration of cabin air filters into vehicle design and HVAC systems presents technical challenges. Space constraints, airflow dynamics, and compatibility with other vehicle components must be carefully considered to ensure seamless integration and optimal performance.

In summary, while significant progress has been made in cabin air filter technology, several challenges persist, including balancing filtration efficiency and airflow resistance, capturing diverse pollutants, ensuring durability and longevity, adapting to geographical variations, and seamless integration into vehicle systems. Overcoming these challenges will be crucial for achieving improved air quality and passenger comfort in vehicles.

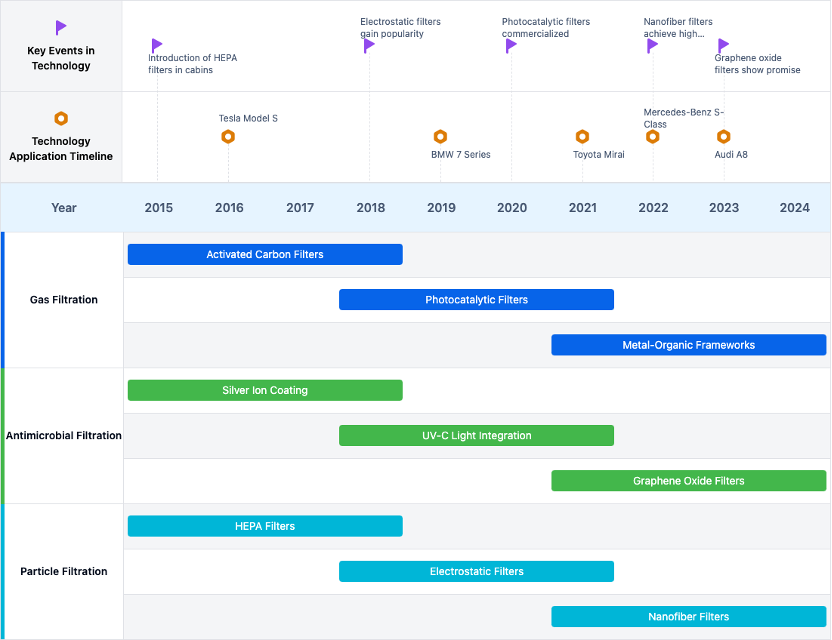

Technology Evolution Path

Current Technical Solutions

Cabin air filter structure and materials

The cabin air filters are designed with various structures and materials to improve their filtering efficiency and performance. Some filters incorporate multiple layers or stages of filtration, while others utilize specialized materials like activated carbon or photocatalytic nanofibers to enhance their ability to remove particulates, gases, and odors from the cabin air.

- Cabin air filter structure

- The cabin air filter structure typically consists of a housing or container that holds the filter material. The housing can be made of various materials, such as thermoplastic, and may include features like closures or seals to ensure proper installation and prevent air leakage. The filter material itself can be designed with different layers or components to effectively capture pollutants and particles.

- Filter materials for cabin air filters

- Various filter materials can be used in cabin air filters to improve their filtering efficiency and performance. These materials may include activated carbon, nanofibers, photocatalytic materials, or adsorption layers. The filter materials can be designed to target specific pollutants, such as particulate matter, organic gases, or microorganisms, providing enhanced air purification for the vehicle cabin.

- Cabin air filter integration with vehicle systems

- Cabin air filters can be integrated with the vehicle’s air conditioning or ventilation systems. This integration may involve specific mounting structures, air flow control mechanisms, or monitoring systems. These features allow for efficient air filtration and distribution within the cabin, as well as potential monitoring and maintenance of the filter’s condition.

- Cabin air filter cleaning and maintenance

- To ensure optimal performance and extend the lifespan of cabin air filters, various cleaning and maintenance approaches can be employed. These may include removable filter cores, cleaning systems, or filter replacement mechanisms. Proper maintenance helps maintain air quality within the vehicle cabin and prevents clogging or reduced efficiency of the filter over time.

Cabin air filter monitoring and control systems

Various systems and methods are developed to monitor the condition and usage of cabin air filters in vehicles. These systems can detect when the filter needs to be replaced, analyze the filter element’s performance, and even automatically control the cabin air filtration process based on the filter’s condition or external factors like air quality.

Cabin air filter integration with HVAC systems

The cabin air filters are designed to integrate seamlessly with the vehicle’s heating, ventilation, and air conditioning (HVAC) systems. This integration allows for efficient air filtration and distribution throughout the cabin, ensuring a comfortable and healthy environment for the occupants.

Specialized cabin air filters for specific applications

Some cabin air filters are designed for specific applications or environments, such as filters for aircraft cabins, excavators, or negative pressure isolation cabins. These specialized filters are tailored to meet the unique requirements of their respective applications, ensuring optimal air quality and protection for the occupants.

Cabin air filter testing and evaluation methods

Various methods and test setups are developed to evaluate the performance and efficiency of cabin air filters. These methods may involve testing the filters’ ability to remove particulate matter, gaseous pollutants, or other contaminants, as well as assessing their durability and resistance to deformation or leakage.

Key Players Analysis

The competitive landscape for the issue of improving the filtering effect of cabin air filters can be analyzed from several dimensions. The industry is currently in a mature stage with a significant market size driven by increasing awareness of air quality and health concerns. Companies like MANN+HUMMEL GmbH and MAHLE International GmbH are leading players with advanced technologies and extensive market presence, indicating high technical maturity. UFI INNOVATION CENTER Srl and Donaldson Co., Inc. are also key competitors, contributing to innovation and market diversity. 3M Innovative Properties Co. brings unique material science expertise, further enhancing the technological landscape. Overall, the market is characterized by high competition and continuous innovation.

MANN+HUMMEL GmbH

MANN+HUMMEL GmbH has developed advanced cabin air filters that utilize nanofiber technology to enhance filtration efficiency. Their filters are designed to capture ultrafine particles, allergens, and harmful gases, providing cleaner air inside the vehicle cabin.

UFI INNOVATION CENTER Srl

UFI INNOVATION CENTER Srl offers cabin air filters that incorporate activated carbon layers to remove odors and harmful gases. Their filters are designed to provide long-lasting performance and are used in various automotive applications.

Donaldson Co., Inc.

Donaldson Co., Inc. has developed cabin air filters that use electrostatic precipitation technology to capture a wide range of airborne contaminants. Their filters are known for their durability and high filtration efficiency.

MAHLE International GmbH

MAHLE International GmbH offers cabin air filters that utilize multi-layer filtration technology, combining mechanical and electrostatic filters to capture particles and gases. Their filters are designed for high performance and long service life.

3M Innovative Properties Co.

3M Innovative Properties Co. has developed cabin air filters that use a combination of electrostatic and carbon filtration technologies. Their filters are designed to capture a wide range of contaminants, including particles, allergens, and gases, providing comprehensive air purification.

Key Technology Interpretation

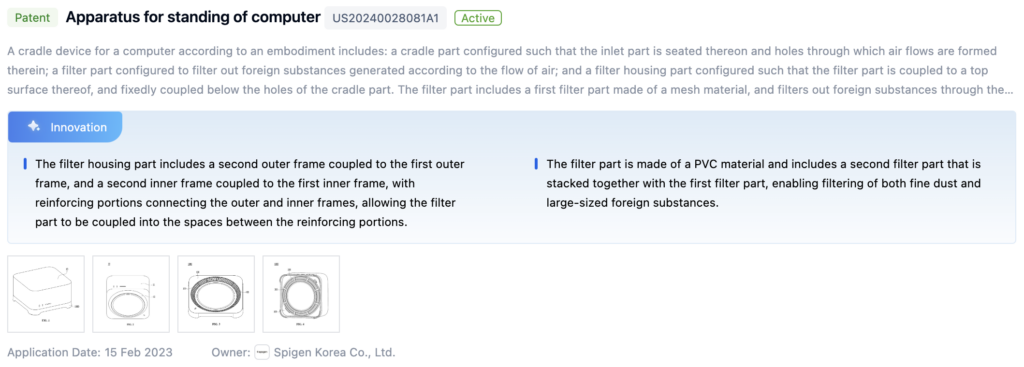

Patent1:Apparatus for standing of computer

Paper 1:Restoring South African subtropical succulent thicket using <i>Portulacaria afra</i>: exploring the rooting window hypothesis.

Potential Innovation Directions

- Cabin air filter structure and materials

- Cabin air filter monitoring and control systems

- Specialized cabin air filters for specific applications

- Cabin air filter integration with HVAC systems

Regulatory and Environmental Considerations

Health and Safety Standards

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!