Technical Background and Objectives of Torque Wrenches

Torque wrenches are essential tools used in various industries including automotive, aerospace, and manufacturing to ensure proper tightening of fasteners with precise torque values. The ability to adjust the length of a torque wrench is crucial for accessing confined spaces and achieving optimal leverage during operation. However, existing adjustable-length torque wrenches often face challenges in maintaining accuracy and repeatability across different length settings.

The primary objective of this research is to explore innovative solutions that can significantly improve the adjustable length performance of torque wrenches while maintaining or enhancing their accuracy, durability, and ease of use. This technological advancement would address the growing demand for versatile and reliable torque tools in various industrial applications where precise torque control is critical for product quality, safety, and efficiency.

The research aims to investigate new design concepts, materials, and manufacturing techniques that can enable seamless length adjustment without compromising the torque wrench’s calibration or introducing additional sources of error. Potential areas of exploration include novel mechanisms for length adjustment, advanced materials with improved strength-to-weight ratios, and innovative calibration methods to ensure consistent torque readings across different length settings.

To get detailed scientific explanations of torque wrenches, try Patsnap Eureka TechResearch.

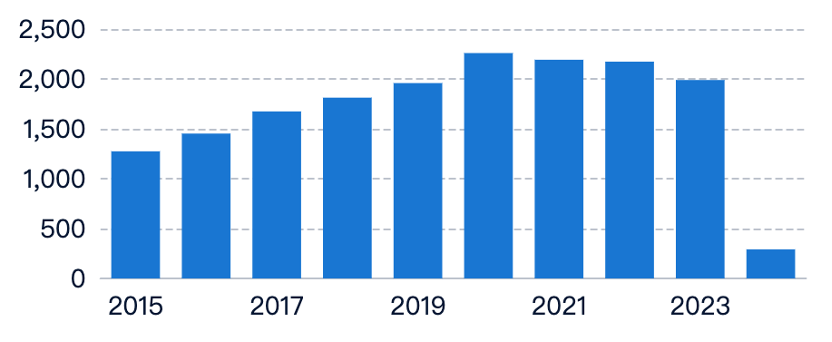

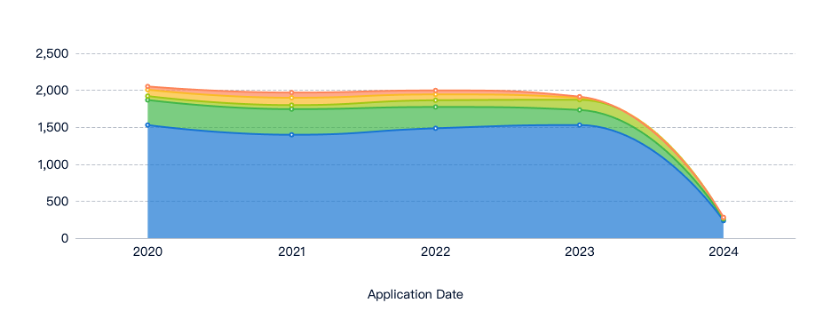

Market Demand Analysis for Torque Wrenches

The market demand for torque wrenches with adjustable length performance is driven by various industries that require precise torque control and versatility in confined spaces. The automotive industry is a significant consumer, as torque wrenches are essential for assembling and maintaining vehicles, particularly in areas with limited access. The aerospace industry also relies heavily on adjustable-length torque wrenches for aircraft maintenance and assembly, where space constraints are common.

Additionally, the construction and manufacturing sectors have a substantial need for these tools as they are used in the installation and maintenance of machinery, equipment, and structures. The oil and gas industry, which often operates in challenging environments, also requires adjustable-length torque wrenches for tasks such as pipeline installation and maintenance.

The market demand for adjustable-length torque wrenches is driven by several factors, including the need for increased efficiency, safety, and ergonomics in various industrial settings. These tools allow workers to access tight spaces and apply precise torque without compromising their safety or the quality of the work.

Furthermore, the growing emphasis on workplace safety and ergonomics has contributed to the demand for adjustable-length torque wrenches. These tools reduce the risk of musculoskeletal disorders and injuries associated with awkward postures and excessive force, thereby improving worker safety and productivity.

Current State and Challenges in Torque Wrenches

The current state of adjustable length torque wrenches presents several challenges that hinder their widespread adoption and optimal performance:

- Lack of Standardization: Inconsistencies in design and manufacturing processes lead to variations in quality and reliability across different brands and models.

- Durability Concerns: The adjustable length mechanisms are prone to wear and tear, which can reduce accuracy over time.

- Ease of Use: Complex mechanisms may require specialized tools or expertise for proper adjustment, increasing the risk of user error.

- Cost Considerations: High-quality adjustable length torque wrenches can be expensive, limiting their accessibility in certain markets.

Addressing these challenges through innovative design solutions, improved manufacturing processes, and increased accessibility will be crucial for the widespread adoption and optimal performance of these essential tools.

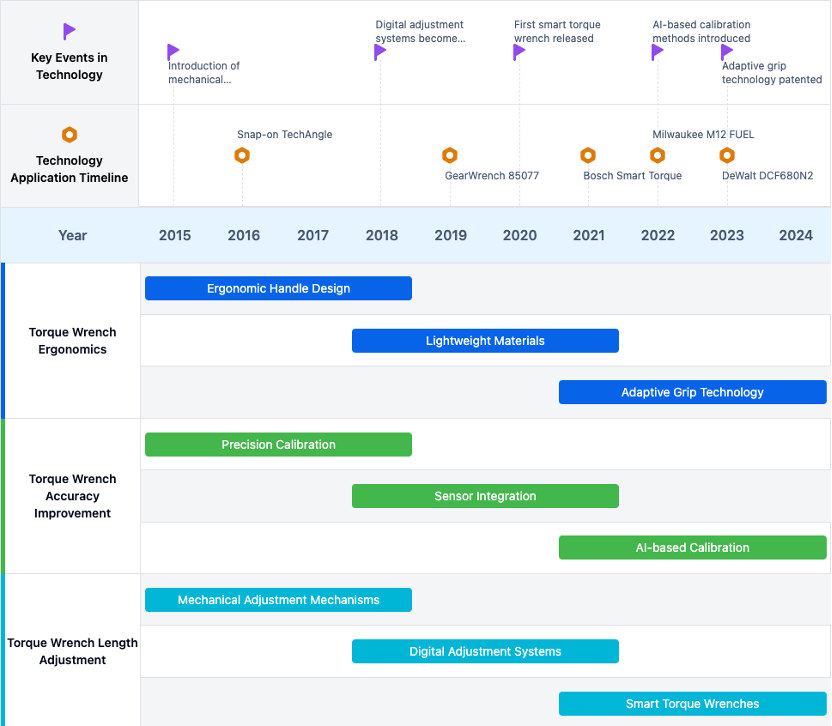

Technology Evolution Path

Current Technical Solutions for Torque Wrenches

Adjustable Length:

- Adjustable Length Handle: Some feature an adjustable length handle, allowing the user to extend or retract the handle to suit different applications or access tight spaces. This adjustability provides better leverage and accessibility.

- Quick Torque Adjustment: Certain torque wrenches are designed for quick and easy adjustment of the torque setting, enabling efficient switching between different torque requirements.

Torque Settings:

- Mechanisms for Adjusting Torque: Many torque wrenches have mechanisms that allow the user to adjust the torque setting, ensuring precise torque application across various applications.

Locking Mechanisms:

- Preventing Unintentional Adjustments: Locking mechanisms secure the torque setting or length adjustment, enhancing reliability and accuracy.

Specialized Designs:

- Adjustable Wrench Heads: Some torque wrenches feature adjustable wrench heads that can be rotated or repositioned to access different angles or tight spaces, improving versatility.

Key Players Analysis in Torque Wrenches

Hangzhou Perine Tools Co. Ltd.:

- Offers a cost-effective torque wrench with adjustable length, focusing on general use with a balance between performance and affordability.

Milwaukee Electric Tool Corp.:

- Developed an advanced torque wrench with adjustable length features, incorporating digital displays for accurate torque measurements and easy adjustments.

Apex Brands Inc.:

- Offers a torque wrench with a unique adjustable length mechanism, emphasizing user-friendly design and robust construction for various industrial applications.

The Black & Decker Corp.:

- Introduced a torque wrench with adjustable length capabilities, featuring ergonomic handles and a reliable locking mechanism for consistent performance.

Ingersoll-Rand Industrial U.S. Inc.:

- Provides a torque wrench with adjustable length, focusing on high torque accuracy and ease of use, designed for heavy-duty industrial applications.

Key Technology Interpretation in Torque Wrenches

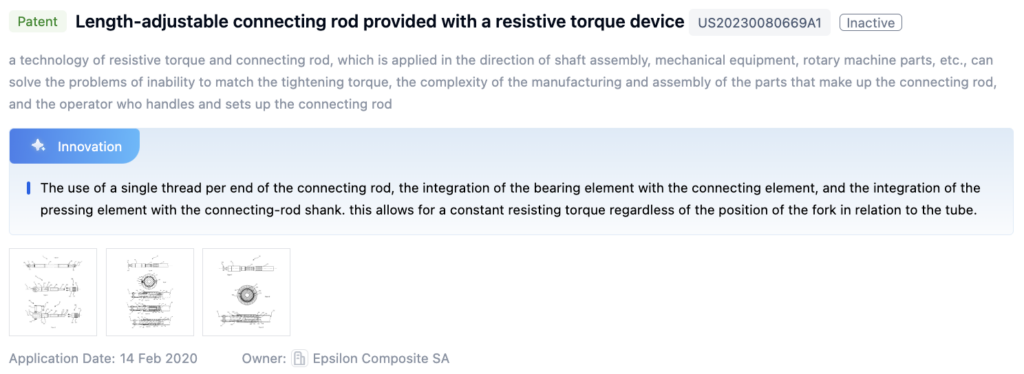

Patent 1: Length-Adjustable Connecting Rod Provided with a Resistive Torque Device

- Core Points:

- Single Thread per End: Allows for constant resisting torque regardless of the position of the fork in relation to the tube.

- Integration of Bearing and Connecting Elements: Simplifies assembly and reduces manufacturing complexity.

Patent 2: Torch with Adjustable Features

- Core Points:

- Adjustable Length and Torch Head Angle: Customizable to different job requirements, enhancing flexibility.

- Ergonomic Design: Provides a comfortable grip for easier handling and operation.

Paper 1: Adjustable Stiffness Torsional Magnetic Spring with Linear Stroke Length

- Core Points:

- Stiffness Adjustment: Achieves clinically effective torque in orthodontic archwires through adjustable torsional stiffness.

Potential Innovation Directions for Torque Wrenches

Length Handles:

- Versatility and Accessibility: Enhances the usability of the wrench in tight spaces or different applications.

Torque Settings:

- Precision and Control: Ensures the wrench can be used for a wide range of applications.

Wrench Heads:

- Flexibility: Allows access to different angles or tight spaces.

Locking Mechanisms for Torque Adjustment:

- Consistency and Accuracy: Secures the torque setting to prevent accidental changes.

Regulatory and Compliance Considerations for Torque Wrenches

Compliance with relevant industry standards and regulations is essential for the development and commercialization of torque wrenches with adjustable length performance. Key standards include ISO, ANSI, and BSI guidelines for design, manufacturing, and testing.

Environmental Impact and Sustainability of Torque Wrenches

Environmental impact and sustainability are crucial considerations in the development of torque wrench technology. The use of non-renewable resources, hazardous materials, and energy-intensive manufacturing processes can have significant environmental implications. Manufacturers should explore the use of recycled or renewable materials, implement efficient manufacturing processes, and design products with end-of-life considerations in mind to promote sustainability.

By addressing these aspects and continuously innovating, torque wrench technology can significantly improve, leading to more efficient, reliable, and environmentally sustainable tools for various industries.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!