Graphene Oxide Conductivity Goals and Challenges

Enhancing the conductivity of graphene oxide (GO) is essential for various applications in electronics, energy storage, and sensing. GO’s unique properties are limited by poor electrical conductivity due to oxygen-containing functional groups disrupting the π-electron system. Strategies to improve conductivity include:

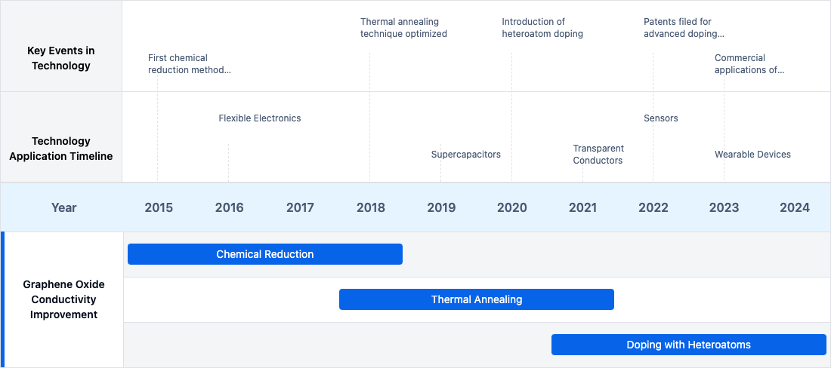

- Chemical Reduction: Removing oxygen groups with agents like hydrazine or sodium borohydride, but often leaving structural defects.

- Thermal Annealing: Heating above 1000°C to restore the π-electron system, risking structural damage.

- Doping: Adding metals or polymers to modify the electronic structure, improving charge transfer.

Novel approaches include plasma treatment, laser irradiation, and composite integration. The challenge is achieving scalable, cost-effective methods that preserve GO’s properties.

To get a detailed scientific explanations of Graphene Oxide, try Eureka.

Market Demand for High-Conductivity Graphene Oxide

The demand for high-conductivity GO spans multiple industries:

- Energy Storage: Enhanced GO electrodes improve battery and supercapacitor performance.

- Electronics: GO is ideal for flexible, wearable electronics due to its properties and potential high conductivity.

- Sensors: Conductive GO-based sensors offer better sensitivity and selectivity.

Other applications include catalysis, water treatment, and biomedical fields, driven by the need for advanced materials.

Current State and Limitations of Graphene Oxide Conductivity

GO’s conductivity is hindered by oxygen groups acting as defects. Methods to improve this include:

- Chemical Reduction: Partially restores conductivity but can cause defects.

- Thermal Annealing: Removes oxygen groups but requires precise control.

- Doping: Effective but depends on dopant type and method.

Despite improvements, GO’s conductivity remains lower than pristine graphene, limiting its applications.

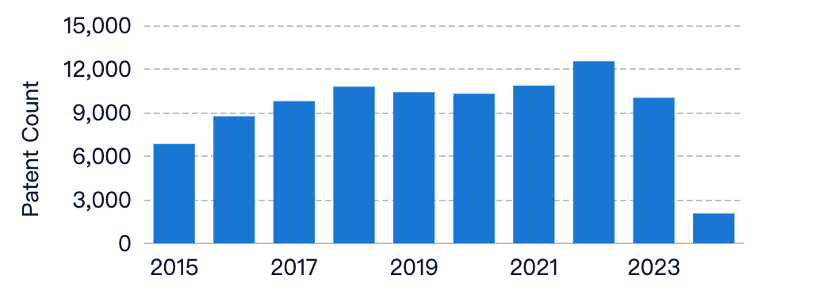

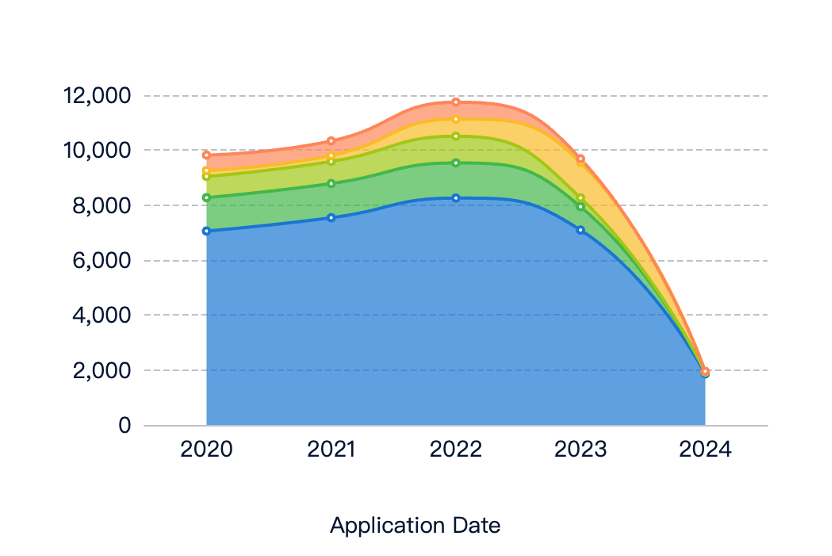

Evolution of Graphene Oxide Conductivity Enhancement Techniques

Detailed study on the historical progress and new advancements in techniques to enhance GO conductivity.

Existing Solutions for Enhancing Graphene Oxide Conductivity

- Chemical Reduction: Using agents to restore the π-electron system.

- Conductive Composites: Combining GO with materials like metals or polymers.

- Doping: Introducing heteroatoms to improve electronic structure.

- Conductive Films: Processing GO into high-conductivity films using techniques like spin-coating.

Key Players in Graphene Oxide Research and Industry

Chinese Academy of Sciences

Research includes bioelectricity harvesting, redox flow batteries, thermal conduction materials, superhydrophobic coatings, and electromagnetic wave absorption.

Semiconductor Energy Laboratory Co. Ltd.

Focus on practical applications and commercializing graphene oxide technologies.

Samsung Electronics Co. Ltd.

Developing graphene oxide-based technologies for electronics, displays, and energy storage.

LG Energy Solution Ltd.

Research targets improving conductivity for lithium-ion batteries and supercapacitors.

Beijing University of Chemical Technology

Studies on composites for energy storage, thermal management, and environmental remediation.

Core Innovations in Graphene Oxide Conductivity

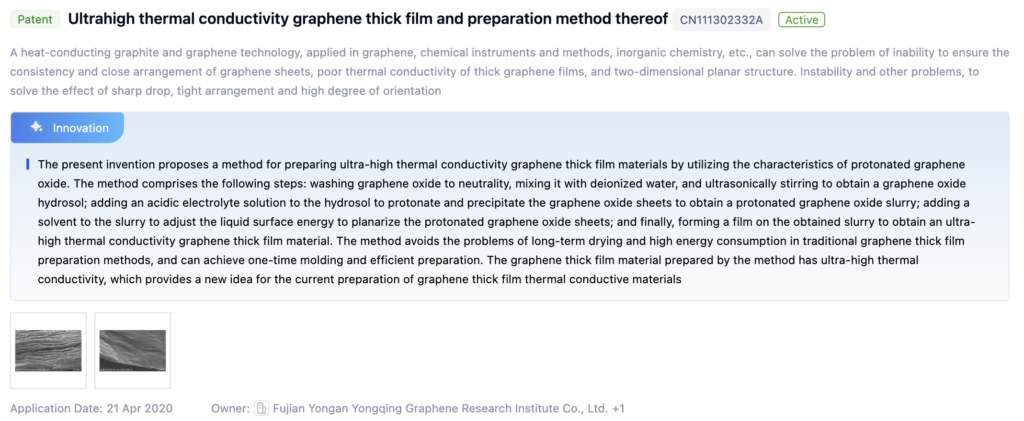

Patent 1: Ultrahigh Thermal Conductivity Graphene Thick Film

- Core Invention Points:

- Protonated graphene oxide slurry.

- Adjusting liquid surface energy.

- Efficient film formation with high thermal conductivity.

Patent 2: Graphene Film with Ultrahigh Flexibility and High Thermal Conductivity

- Core Invention Points:

- Use of ultra-large graphene oxide sheets.

- Formation of porous structure and densification.

- High-temperature annealing for defect repair.

Paper 1: Investigation of Ceramic Based Composites Using 2D Graphene Filler

- Core Invention Points:

- Synthesis of GO and rGO confirmed by FTIR and XRD.

- rGO used as filler in piezoelectric ceramic material.

- Characterization of composite’s electrical conductivity.

Potential Breakthroughs in Graphene Oxide Conductivity

- Reduction Techniques: Removing oxygen groups to restore conductivity.

- Conductive Composites: Combining GO with conductive materials for enhanced properties.

- Modification Methods: Doping and functionalization to improve conductivity.

- Conductive Films and Coatings: Fabrication techniques for high-conductivity films.

- Modeling and Analysis: Computational methods to predict and enhance conductivity.

Environmental Impact of Graphene Oxide Production

GO production involves strong oxidizing agents, hazardous waste, and significant environmental impact. Strategies to mitigate this include:

- Green Synthesis Methods: Using environmentally friendly oxidizing agents.

- Solvent Recycling: Reducing fresh solvent consumption.

- Waste Treatment: Proper disposal and treatment of hazardous waste.

- Life Cycle Assessment: Identifying environmental hotspots.

- Regulatory Compliance: Adhering to environmental regulations.

Regulatory Landscape for Graphene-Based Materials

The regulatory framework for graphene-based materials includes guidelines from:

- European Union (REACH): Governs production and use of nanomaterials.

- United States (EPA and OSHA): Ensures safety and environmental impact assessments.

- OECD: Promotes international cooperation in nanomaterial regulation.

Efforts are ongoing to harmonize regulations globally and ensure responsible development and use of graphene-based materials.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!