Ceramic Coating Cooling Goals and Background

Ceramic coatings have emerged as a promising solution for enhancing the cooling efficiency of various systems, including aerospace components and industrial machinery. The primary goal of improving the cooling effect of ceramic coatings is to dissipate heat more effectively, thereby reducing operating temperatures and prolonging the lifespan of critical components.

The pursuit of better cooling performance through ceramic coatings is driven by the increasing demand for high-performance systems in industries such as aerospace, automotive, and electronics. These industries require advanced thermal management solutions to maintain optimal operating conditions while ensuring energy efficiency and environmental sustainability. Historically, ceramic coatings have been valued for their thermal insulation properties, protecting materials from extreme temperatures. However, recent advancements have opened new avenues for leveraging ceramic coatings as active cooling solutions by engineering their composition, microstructure, and surface properties to enhance heat dissipation.

The motivation for improving ceramic coating cooling effects stems from the limitations of traditional cooling methods, which often rely on bulky systems like heat sinks or liquid cooling, adding complexity and maintenance requirements. In contrast, ceramic coatings offer the potential for passive cooling, leveraging their intrinsic material properties to reduce the need for additional cooling components and simplify system integration.

To get detailed scientific explanations of the ceramic coatings, try Patsnap Eureka TechResearch.

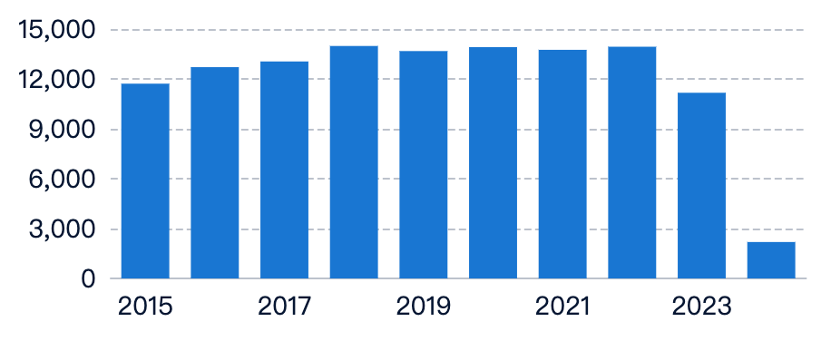

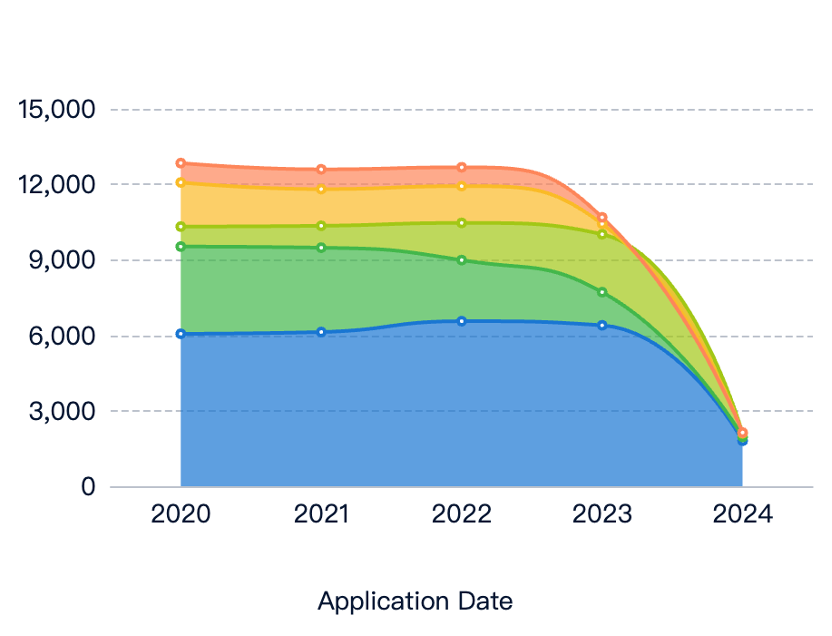

Market Demand for Enhanced Cooling Coatings

The market demand for enhanced cooling coatings has been steadily increasing, driven by the need for improved thermal management in various industries:

- Automotive Industry: The need for efficient engine cooling systems and the growing adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs) have increased the demand for effective thermal management solutions to extend battery life and ensure optimal performance.

- Aerospace Industry: Aircraft engines and avionics systems operate under extreme temperatures, requiring effective heat dissipation to maintain reliability and prevent failures. Enhanced cooling coatings can reduce cooling system weight, leading to increased fuel efficiency and reduced emissions.

- Electronics Industry: As electronic devices become more powerful and compact, effective heat dissipation is critical to prevent overheating and ensure reliable operation, particularly in applications such as computer processors, power electronics, and LED lighting systems.

- Renewable Energy: The growing demand for renewable energy sources like concentrated solar power (CSP) and nuclear power has created a need for advanced cooling coatings to improve the efficiency and durability of solar receivers and reactor components.

Overall, the market for enhanced cooling coatings is expected to grow as industries continue to seek advanced thermal management solutions.

Current State and Challenges of Ceramic Coatings

Ceramic coatings are valued for their thermal insulation properties and ability to withstand extreme temperatures, but they face several challenges:

- Limited Thermal Conductivity: While ceramics are excellent insulators, their low thermal conductivity can lead to inefficient heat dissipation, especially in applications with high heat loads, potentially causing localized hotspots and compromising performance.

- Brittleness and Cracking: Ceramic coatings are inherently brittle and susceptible to cracking due to thermal cycling, mechanical stresses, and environmental factors, which can compromise their effectiveness.

- Adhesion Issues: Poor adhesion to substrates can result in premature failure, delamination, and reduced service life, especially for complex geometries and dissimilar material combinations.

- Manufacturing Complexity: The production of ceramic coatings often involves high temperatures, specialized equipment, and stringent environmental controls, limiting scalability and cost-effectiveness, particularly for large-scale applications.

- Geographical Disparities: The uneven distribution of ceramic coating technology across regions can create barriers to adoption and hinder global collaboration.

Addressing these challenges requires continued research in material science, coating processes, and application-specific optimization.

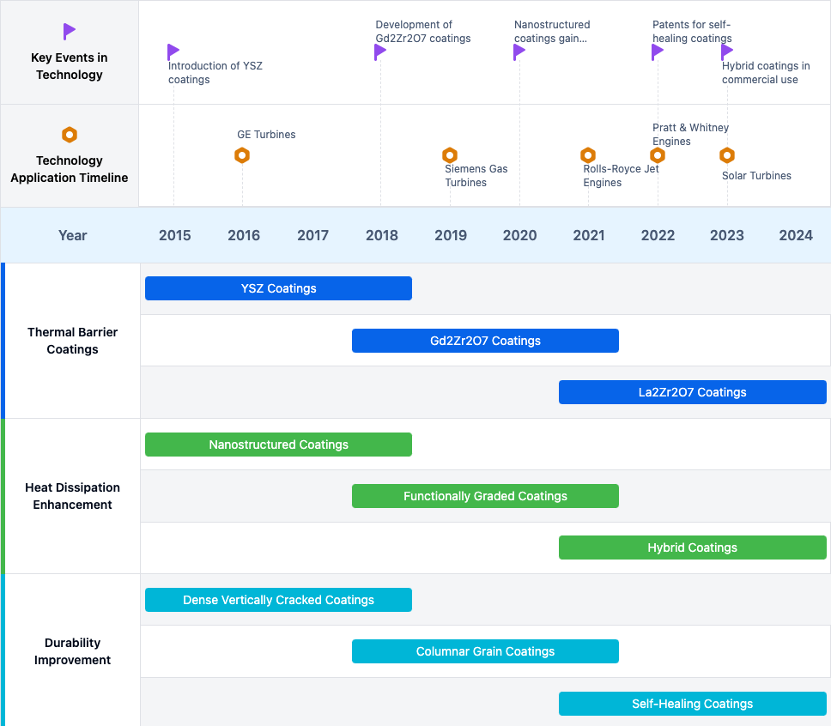

Evolution of Ceramic Cooling Technologies

Existing Solutions for Cooling Ceramic Coatings

Improved Thermal Insulation

- Low Thermal Conductivity: Coatings designed with low thermal conductivity reduce heat transfer and enhance cooling performance by maintaining desired temperature levels on various substrates.

- Hollow or Porous Structures: Incorporating air pockets or voids within the coating material further reduces thermal conductivity, providing enhanced insulation.

- Multilayer Thermal Barrier Coatings: These coatings consist of multiple layers, each with specific functions like adhesion, thermal protection, and environmental resistance, offering enhanced insulation and durability.

Enhanced Radiative Cooling

- High Emissivity Coatings: Formulated to have high infrared emissivity, these coatings radiate heat more effectively, increasing the rate of heat dissipation from the surface.

- Radiative Cooling Paints and Coatings: Using specific pigments or materials, these coatings are designed for selective infrared emission and solar reflection, providing passive cooling.

Enhanced Surface Roughness

- Surface Roughness for Improved Cooling: Increased surface roughness promotes turbulent airflow and enhances convective heat transfer, achieved through plasma spraying or incorporating ceramic particles.

- Tailored Porosity: Controlled porosity improves air circulation and heat transfer, enhancing cooling capabilities.

Ceramic Coatings with Phase Change Materials

- Phase Change Materials (PCMs): These materials absorb and release heat during phase transitions, providing a cooling effect and regulating temperatures, applicable in electronics, batteries, and building materials.

Key Players in Ceramic Coating Industry

Siemens Energy Global GmbH & Co. KG

Developed advanced ceramic coatings with enhanced cooling properties for gas turbines, focusing on improving thermal barrier coatings (TBCs) using innovative materials and techniques.

Ningbo Institute of Material Technology & Engineering of CAS

Working on innovative ceramic coatings offering superior cooling effects through the use of composite materials and novel fabrication methods.

Tata Steel Ltd.

Exploring ceramic coatings to improve cooling effects in industrial applications, integrating ceramic materials with steel products to enhance thermal management.

Shanghai Institute of Ceramics Chinese Academy of Sciences

Focused on high-performance ceramic coatings with improved cooling effects, utilizing nanostructured materials and advanced deposition techniques.

Northwestern Polytechnical University

Researching advanced ceramic coatings with enhanced cooling properties for aerospace applications, including multi-layered coatings and rare earth elements.

Core Innovations in Ceramic Cooling Technologies

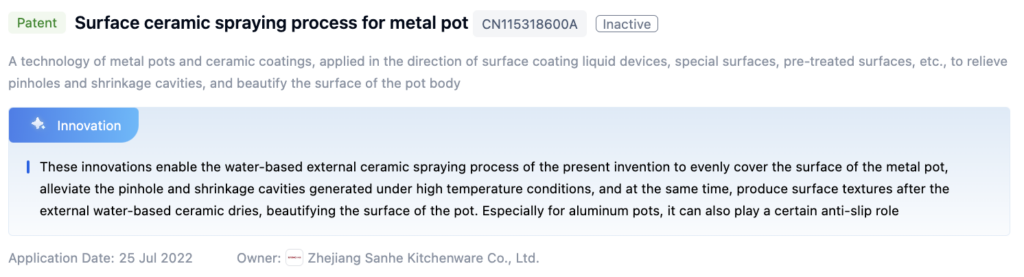

Patent 1: Surface Ceramic Spraying Process for Metal Pot

- Core Points:

- Even Coverage: Alleviates pinholes and shrinkage cavities under high temperatures.

- Surface Texture: Produces surface textures after the ceramic dries, beautifying the pot.

- Anti-Slip Role: Especially beneficial for aluminum pots, providing an anti-slip function.

Patent 2: Method for Producing Nickel-Based Alloy Product or Titanium-Based Alloy Product

- Core Points:

- Local Cooling: Increases cooling rate in complex shapes like aircraft engine components.

- Effective Cooling: Ensures effective cooling of disk-shaped metal materials.

Potential Breakthroughs in Cooling Ceramic Coatings

Improved Thermal Insulation Properties

Ceramic coatings with enhanced thermal insulation can reduce heat transfer, improving cooling efficiency by incorporating materials with low thermal conductivity or porous structures.

Reflective Properties

Reflective ceramic coatings help reflect heat away from the surface, enhancing cooling by incorporating materials with high reflectivity or specific compositions that enhance thermal radiation reflection.

Phase Change Materials

Incorporating PCMs into ceramic coatings provides a cooling effect through latent heat absorption and release during phase transitions, improving thermal management.

Enhanced Porosity

Coatings with increased porosity can improve heat dissipation through air circulation and convection, achieved by incorporating pore-forming agents or using specific deposition methods.

Heat-Dissipating Additives

Formulating ceramic coatings with high thermal conductivity additives like metal particles or carbon nanotubes can improve heat transfer away from the surface, enhancing cooling efficiency.

Environmental Impact of Ceramic Coatings

The production, application, and disposal of ceramic coatings can impact the environment. Manufacturing may involve hazardous materials, energy-intensive processes, and waste generation. Proper waste management, recycling, and energy-efficient technologies can minimize the environmental footprint. The positive impact includes improved thermal efficiency, reduced energy consumption, and lower greenhouse gas emissions. However, the potential release of nanoparticles during application must be monitored to prevent environmental contamination.

Regulatory Landscape for Ceramic Coatings

The regulatory landscape for ceramic coatings focuses on environmental impact, safety standards, and industry-specific requirements. Regulations often target the reduction of VOCs and other harmful emissions during the application and curing processes. Industry-specific guidelines ensure the performance, durability, and safety of ceramic coatings in applications like aerospace and automotive. Compliance with regulations is essential to avoid penalties, product recalls, and reputational damage.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!