Technical Background and Objectives

Valve-regulated lead-acid (VRLA) batteries, also known as AGM (Absorbed Glass Mat) batteries, have gained widespread adoption in various applications due to their maintenance-free operation, leak-proof design, and high energy density. However, improving the cycle life of AGM batteries remains a critical challenge, as their performance can degrade over time due to factors such as sulfation, grid corrosion, and active material shedding.

The cycle life of AGM batteries is closely tied to their ability to withstand repeated charge-discharge cycles without significant capacity loss or internal degradation. Enhancing the cycle life not only extends the battery’s usable lifespan but also contributes to cost-effectiveness and environmental sustainability by reducing the need for frequent replacements.

The primary objective of this research is to explore innovative approaches and technologies that can significantly improve the cycle life of AGM batteries. This includes investigating advanced materials, optimizing battery design and manufacturing processes, and developing effective battery management strategies. By addressing the underlying causes of capacity fade and internal degradation, this research aims to unlock the full potential of AGM batteries, enabling their widespread adoption in applications that demand extended cycle life, such as renewable energy storage, electric vehicles, and backup power systems.

Market Demand Analysis

The market demand for AGM (Absorbed Glass Mat) batteries is driven by various industries and applications that require reliable and maintenance-free energy storage solutions. AGM batteries offer several advantages over traditional lead-acid batteries, including improved cycle life, higher energy density, and better resistance to vibration and shock.

One of the primary markets for AGM batteries is the automotive industry, particularly for start-stop systems and micro-hybrid vehicles. These systems require batteries with excellent cycling capabilities and the ability to withstand frequent charge-discharge cycles. AGM batteries’ longer cycle life and higher charge acceptance make them well-suited for these applications.

Another significant market is the renewable energy sector, where AGM batteries are used in off-grid solar and wind power systems as backup power sources or energy storage solutions. Their low self-discharge rate and deep-cycle capabilities make them ideal for these applications, ensuring reliable power supply even during extended periods of low or no energy generation.

The telecommunications industry also relies heavily on AGM batteries for backup power in cellular base stations, data centers, and other critical infrastructure. The maintenance-free nature of AGM batteries and their ability to operate in a wide range of temperatures make them a preferred choice in this sector.

Additionally, AGM batteries are widely used in various industrial applications, such as uninterruptible power supplies (UPS), emergency lighting systems, and material handling equipment. Their resistance to vibration and shock, combined with their long service life, makes them well-suited for these demanding environments.

As the demand for sustainable and reliable energy storage solutions continues to grow, the market for AGM batteries is expected to expand further. The increasing adoption of renewable energy sources, the rise of electric vehicles, and the need for backup power in critical infrastructure will drive the demand for batteries with improved cycle life and performance characteristics, which AGM batteries can provide.

However, it is important to note that the market for AGM batteries is also influenced by factors such as the availability of alternative battery technologies, regulatory policies, and the overall economic conditions in different regions. Continuous research and development efforts to improve the cycle life and cost-effectiveness of AGM batteries will be crucial in maintaining their competitiveness and meeting the evolving market demands.

Current State and Challenges

The cycle life of AGM (Absorbed Glass Mat) batteries is a critical factor that determines their overall performance and longevity. Currently, the cycle life of AGM batteries faces several challenges that hinder their widespread adoption in applications requiring frequent charging and discharging cycles.

One of the primary challenges is the degradation of the positive electrode material, typically lead dioxide (PbO2). During the charging and discharging cycles, the positive electrode undergoes structural changes and volume expansions, leading to the shedding of active material and a gradual loss of capacity. This phenomenon is exacerbated by the formation of lead sulfate crystals, which can cause mechanical stress and further deterioration of the electrode.

Another significant challenge is the corrosion of the grid and current collectors within the battery. The acidic environment and the presence of oxygen during the charging process can lead to the oxidation and degradation of the grid material, typically lead or lead alloys. This corrosion can result in increased internal resistance, reduced conductivity, and ultimately, a shorter cycle life.

Additionally, the electrolyte in AGM batteries can undergo various chemical and physical changes over time, contributing to the degradation of the battery’s performance. The electrolyte can become depleted or contaminated, affecting the ionic conductivity and the overall electrochemical reactions within the battery.

Furthermore, the thermal management of AGM batteries during cycling is a significant challenge. High temperatures can accelerate the degradation processes, while low temperatures can impede the electrochemical reactions and reduce the available capacity. Maintaining an optimal temperature range is crucial for maximizing the cycle life.

Geographically, the challenges associated with AGM battery cycle life are prevalent across various regions, as the demand for these batteries spans multiple industries and applications, including renewable energy systems, backup power supplies, and electric vehicles. However, regions with extreme climatic conditions or harsh operating environments may face additional challenges in maintaining the cycle life of AGM batteries.

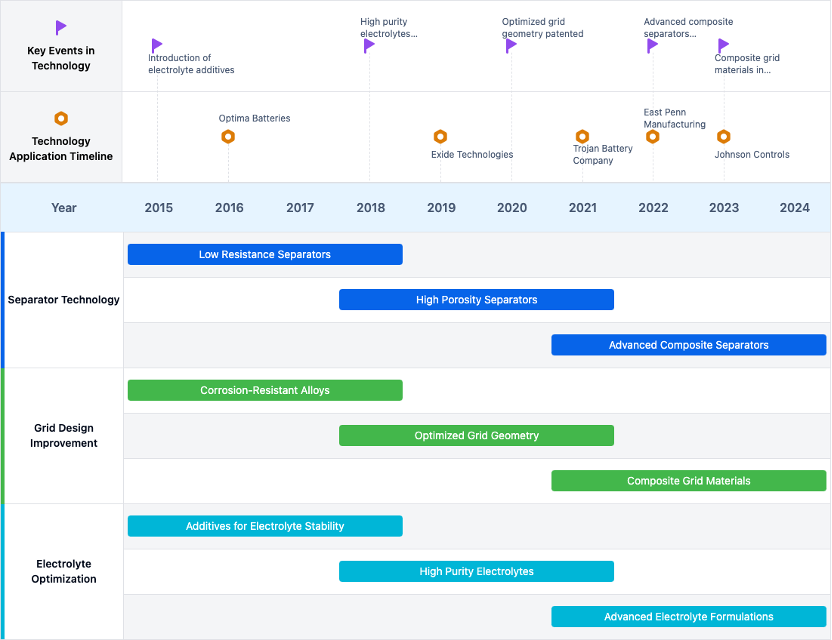

Technology Evolution Path

Current Technical Solutions

AGM battery formation processes

Various formation processes are described for manufacturing AGM (Absorbed Glass Mat) batteries, including processes for internal formation, acid cycle formation, and container formation. These processes aim to optimize the performance and characteristics of the AGM batteries.

- AGM battery formation processes

- Various formation processes are described for AGM (Absorbed Glass Mat) batteries, including internal formation, acid filling, and curing processes. These processes are crucial for ensuring the proper activation and performance of the AGM batteries.

- AGM battery separator structures、

- The search results cover various separator structures for AGM batteries, such as multilayer separators, separators with positioning and perforating structures, and separators designed for high-temperature resistance and prolonged cycle life.

- AGM battery grid and plate group structures

- Several patents describe grid and plate group structures specifically designed for AGM batteries, including punching net grids, tight assembly structures, and structures aimed at preventing cracking and improving cycle life.

- AGM battery cycle life improvement techniques

- Some patents focus on techniques to improve the cycle life of AGM batteries, such as formation methods, separator materials, and battery management systems for estimating and optimizing battery life cycles.

AGM separator designs for improved cycle life

The search results cover various designs and materials for AGM separators, which are crucial components in AGM batteries. These separators are designed to prolong the service life and cycle life of the batteries by improving their performance and durability.

Methods for estimating and predicting battery cycle life

Several methods and techniques are described for estimating and predicting the cycle life of batteries, including AGM batteries. These methods involve analyzing various factors and parameters to accurately determine the remaining cycle life of the batteries.

Improving cycle life through battery design and materials

The search results discuss various approaches to improve the cycle life of batteries, including AGM batteries, through optimized battery designs, materials selection, and manufacturing processes. These approaches aim to enhance the overall performance and longevity of the batteries.

Battery cycle life testing and evaluation methods

Various testing and evaluation methods are described for assessing the cycle life of batteries, including accelerated cycle life testing, rapid evaluation methods, and methods involving acoustic signal analysis. These methods help in understanding and optimizing the cycle life performance of batteries.

Key Players Analysis

The competitive landscape for improving the cycle life of AGM batteries is shaped by the industry’s developmental stage, market size, and technology maturity. The AGM battery market is in a growth phase with increasing demand for longer-lasting energy storage solutions. The market size is expanding due to the rising adoption in automotive and renewable energy sectors. In terms of technology maturity, companies like Tianneng Battery Group Co., Ltd. and Chaowei Power Group Co., Ltd. are leading with advanced research and development capabilities. Contemporary Amperex Technology Co., Ltd. is also a significant player, leveraging its expertise in battery technology. Daramic LLC focuses on innovative separator materials, while ZAF Energy Systems, Inc. is exploring novel chemistries to enhance cycle life.

Tianneng Battery Group Co., Ltd.

Tianneng Battery Group has developed advanced AGM battery technologies focusing on enhancing cycle life. Their approach includes optimizing the lead paste formula and improving the separator materials to reduce sulfation and water loss, which are critical factors affecting the cycle life of AGM batteries.

Contemporary Amperex Technology Co., Ltd.

CATL has been researching advanced materials and manufacturing processes to improve the cycle life of AGM batteries. Their solutions include the use of high-purity lead and advanced grid designs to enhance battery durability and performance over extended cycles.

Daramic LLC

Daramic specializes in battery separators and has developed innovative separator technologies aimed at extending the cycle life of AGM batteries. Their separators are designed to minimize acid stratification and improve electrolyte distribution, which are key to enhancing battery longevity.

ZAF Energy Systems, Inc.

ZAF Energy Systems focuses on advanced battery chemistries and has developed proprietary additives and materials to improve the cycle life of AGM batteries. Their technology aims to reduce sulfation and enhance charge acceptance, leading to longer battery life.

Chaowei Power Group Co., Ltd.

Chaowei Power Group has invested in research to enhance the cycle life of AGM batteries through improved grid alloys and advanced manufacturing techniques. Their approach includes optimizing the battery design to reduce internal resistance and improve overall efficiency.

Key Technology Insights

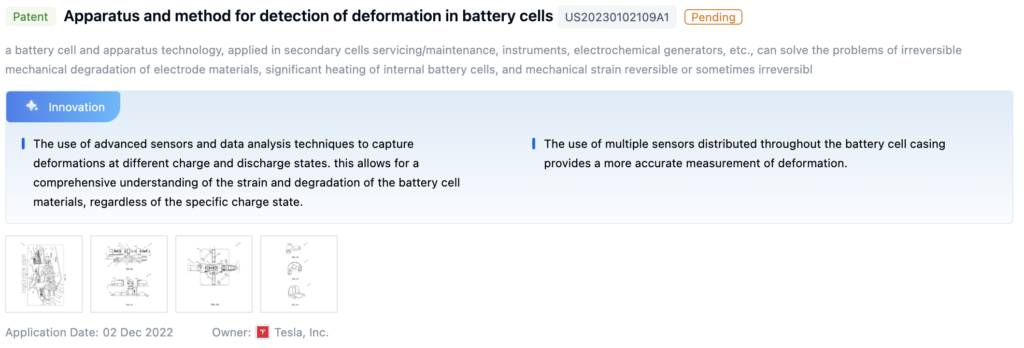

Patent1:Apparatus and method for detection of deformation in battery cells

Paper 1:TEGDME Electrolyte Additive for High-performance Zinc Anodes

Potential Innovation Directions

- Methods for improving AGM battery cycle life

- Techniques for estimating and predicting AGM battery cycle life

- Battery management systems for optimizing AGM battery cycle life

- Accelerated testing methods for evaluating AGM battery cycle life

Environmental Impact and Sustainability

Regulatory and Compliance Considerations

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!