Technical Background and Objectives

Cabin air filters are essential for maintaining a healthy and comfortable environment inside vehicles by removing airborne contaminants such as dust, pollen, and other particulate matter. Over time, the effectiveness of these filters can diminish due to clogging and saturation, leading to reduced air quality and potential health risks for occupants. The goal of improving the dust removal effect of cabin air filters has long been a challenge in the automotive industry. The primary objective is to enhance filtration efficiency and extend the service life of these filters, ensuring optimal air quality throughout the vehicle’s lifespan.

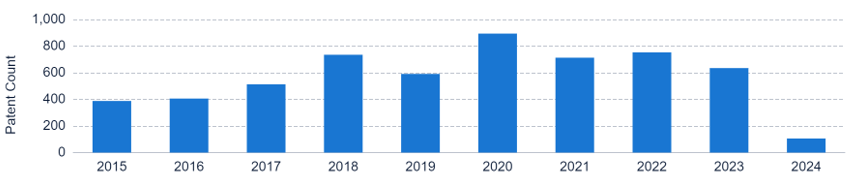

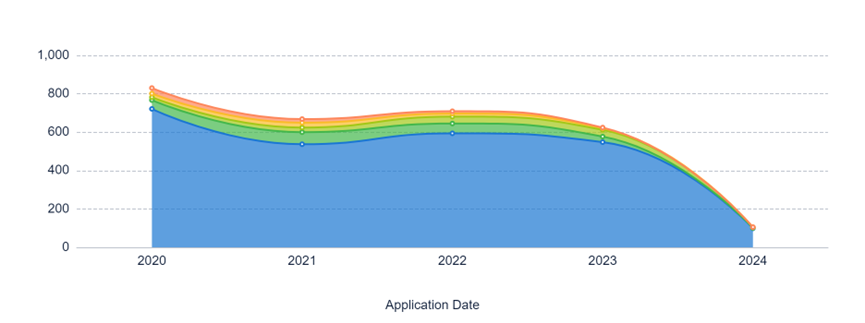

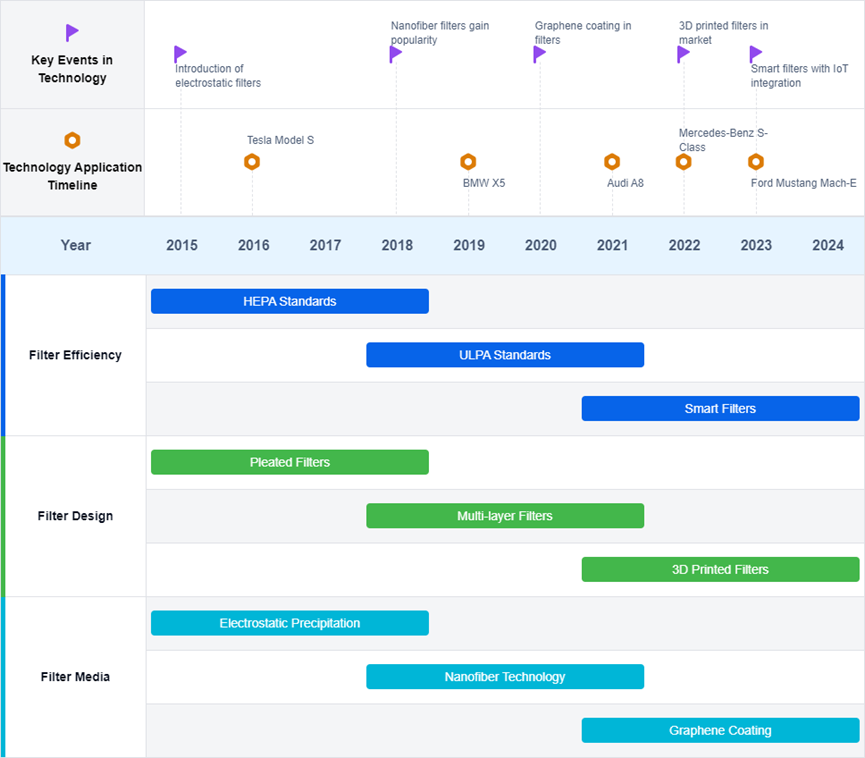

Several factors drive this pursuit. Increasing environmental concerns and stricter emissions regulations have heightened the demand for more effective air filtration systems in vehicles. Additionally, growing consumer awareness of indoor air quality and the rise of electric and hybrid vehicles, which rely heavily on cabin air filtration, further underscore the need for improved filter performance. Technological advancements in materials science, nanotechnology, and filter design have opened new avenues for enhancing the dust removal capabilities of cabin air filters.

To get a detailed scientific explanations of cabin air filter, try Eureka.

Market Demand Analysis

The market demand for improving the dust removal effect of cabin air filters is driven by several factors. There is a growing awareness of the importance of indoor air quality, especially in vehicles where occupants spend significant time. Poor air quality can lead to respiratory issues, allergies, and other health problems, creating a need for effective air filtration solutions.

Urbanization and increasing traffic congestion have led to higher levels of air pollution in many cities worldwide. Particulate matter such as dust and soot can easily enter vehicle cabins, necessitating the use of high-performance air filters to maintain a clean and healthy environment for occupants. Furthermore, the automotive industry’s focus on enhancing passenger comfort and safety has driven the demand for advanced cabin air filtration systems.

Current State and Challenges

The current state of cabin air filter technology presents several challenges. Conventional filter media often fail to capture smaller particles, particularly those in the PM2.5 range, which can enter the cabin and pose health risks. Another challenge is the filter’s susceptibility to clogging, leading to reduced airflow and filtration performance. This not only compromises cabin air quality but also strains the vehicle’s HVAC system, potentially leading to higher energy consumption and maintenance costs.

Durability and longevity of cabin air filters are also concerns, as exposure to harsh environmental conditions can accelerate the degradation of filter materials. Geographical factors, such as high levels of air pollution in certain regions, can necessitate more frequent maintenance or specialized designs. Additionally, integrating cabin air filters into vehicle designs presents challenges related to space constraints, accessibility for maintenance, and compatibility with other vehicle systems.

Technology Evolution Path

Current Technical Solutions

Cabin Air Filter with Dust Removal Mechanism

These filters incorporate various mechanisms to remove dust and particles before entering the vehicle cabin, using vibration, airflow, or mechanical brushes to enhance cleaning efficiency and prolong lifespan.

Cabin Air Filter with Integrated Dust Removal Mechanism

Designed specifically for vehicle cabins, these filters actively remove dust from the media, maintaining airflow and filter efficiency over time. Dust removal mechanisms include vibration, air pulses, or brushes.

Air Filter Assemblies with Detachable Dust Removal Components

These systems feature removable or replaceable components designed for dust removal. This modular design allows efficient maintenance without replacing the entire filter assembly.

Dust Removal Methods for Cabin Air Filters

Various methods, including forced air pulses, vibration mechanisms, and brushes, are employed to remove dust from cabin air filters, extending service life and maintaining optimal air quality.

Cabin Air Filter Systems with Integrated Dust Collection and Removal

These systems filter the air entering the cabin and incorporate mechanisms to collect and remove trapped dust, preventing clogging and maintaining airflow.

Air Filter with Pre-Dust Removal Structure

These filters feature a pre-dust removal stage that captures larger particles and debris, reducing the load on the primary filter and improving overall dust removal performance.

Key Players Analysis

The cabin air filter industry is growing, driven by increased awareness of air quality and health concerns. Significant investments in R&D are enhancing filter efficiency, with key players leading the market.

- Anhui Meiruier Filter Co. Ltd.: Focuses on cost-effective solutions, developing filters using synthetic fibers and electrostatic charge for high dust-holding capacity and long service life.

- Tianjin Shengda Chenyang Auto Parts Co Ltd.: Provides filters with antimicrobial coatings to prevent bacteria and mold growth, improving air quality by inhibiting microbial contamination.

- Farrleey Filtration Co., Ltd.: Offers filters with activated carbon and HEPA technology, effectively removing dust, odors, and harmful gases, providing a healthier in-cabin environment.

- MANN+HUMMEL GmbH: Leading with advanced filtration technologies, utilizing nanofiber technology to capture ultrafine particles like dust, pollen, and allergens, ensuring cleaner air inside vehicle cabins.

- Anhui Gaobo Filtration Technology Co., Ltd.: Specializes in multi-layer filters that combine electrostatic and mechanical filtration for maximum dust removal while maintaining low airflow resistance.

Key Technology Interpretation

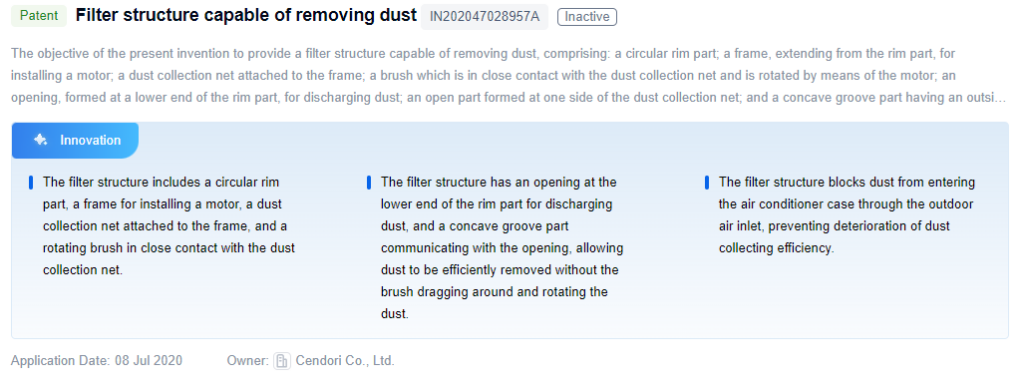

Patent 1: Filter Structure Capable of Removing Dust

- Core Invention Points:

- The structure includes a circular rim part, a motor frame, a dust collection net, and a rotating brush.

- An opening at the lower end and a concave groove part allow efficient dust removal without the brush dragging around.

- The design prevents dust from entering the air conditioner case, maintaining dust collection efficiency.

Patent 2: Dust Removal Structure Utilizing Airflow Whirls and Dust Collector

- Core Invention Points:

- Utilizes an outer barrel, internal barrel, and whirl barrel to create airflow whirl chambers for dust removal.

- A filter at one end of the whirl barrel enhances dust collection efficiency.

- Integrates a motor and suction head assembly for continuous operation.

Potential Innovation Directions

- Cabin Air Filter with Dust Removal Mechanism: These filters use mechanisms like vibration, air pulsing, or mechanical brushes to remove accumulated dust, ensuring sustained airflow and extended filter life.

- Cabin Air Filter with Pre-Filter or Multi-Stage Filtration: Pre-filter stages capture larger particles, reducing the load on the main filter and enhancing overall efficiency. Multi-stage systems target various contaminants, extending filter longevity.

- Cabin Air Filter with Air Flow Optimization: Innovative designs optimize air distribution through the filter, improving particle capture and maintaining energy efficiency.

- Cabin Air Filter with Self-Cleaning or Regeneration Mechanism: Self-cleaning filters use techniques like reverse airflow or ultrasonic vibration to clear dust, extending service life and reducing maintenance needs.

- Cabin Air Filter with Antimicrobial or Air Purification Properties: These filters incorporate antimicrobial materials or coatings to inhibit microorganism growth and may include activated carbon or other agents to improve air quality by removing harmful gases and odors.

Environmental Impact and Regulations

The development of cabin air filters has environmental implications that must be carefully considered. And that’s the meaning of improving the dust removal effect of cabin air filters. The primary concerns include waste generation during production and disposal, and the manufacturing processes’ contribution to greenhouse gas emissions. Manufacturers should explore eco-friendly materials, implement recycling programs, and optimize production processes to reduce environmental impact. Adherence to stringent environmental regulations, such as those set by the EPA and the European Union, is essential for compliance and meeting consumer expectations for sustainable products.

Future Trends in Cabin Air Filters

The future of cabin air filters lies in advanced materials and innovative designs. Promising directions include nanofiber technology for capturing smaller particles, biomimetic designs inspired by natural filtration systems, smart sensing and control systems for adaptive filtration, computational fluid dynamics (CFD) simulations for optimizing filter designs, and self-cleaning or regenerative filter technologies.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!