Electrochemical Performance Goals for AGM Batteries

For AGM (Absorbed Glass Mat) batteries, the primary goal in improving electrochemical performance is to enhance energy density, cycle life, and charge/discharge efficiency. This can be achieved through advancements in materials, electrode design, and electrolyte optimization.

- Increased energy density: Higher energy density allows for longer runtime or smaller battery size for the same capacity. This can be pursued through the development of high-capacity cathode materials, such as lithium-rich layered oxides or high-voltage spinel structures, and the optimization of anode materials, such as silicon-based composites or lithium metal anodes.

- Extended cycle life: Longer cycle life translates to a longer usable lifespan for the battery, reducing the need for frequent replacements. This can be achieved through the use of more stable electrode materials, advanced electrolyte formulations with improved thermal and electrochemical stability, and the incorporation of additives or coatings to mitigate degradation mechanisms.

- Improved charge/discharge efficiency: Higher charge/discharge efficiency leads to reduced energy losses during operation, resulting in better overall battery performance and reduced heat generation. This can be facilitated by optimizing electrode porosity and electrolyte transport properties, as well as minimizing side reactions and internal resistance through advanced cell design and materials selection.

Additionally, safety considerations, such as thermal stability and overcharge protection, should be addressed to ensure the reliable and safe operation of AGM batteries in various applications. Ultimately, the electrochemical performance goals should align with the specific requirements of the target application, balancing factors like energy density, cycle life, and power capability.

Market Demand for High-Performance AGM Batteries

The market demand for improving electrochemical performance of AGM (Absorbed Glass Mat) batteries is driven by various industries and applications that require reliable and efficient energy storage solutions. These batteries are widely used in applications such as uninterrupted power supply (UPS) systems, emergency backup systems, telecommunications, renewable energy systems, and automotive applications.

One of the key drivers for the demand for improving electrochemical performance of AGM batteries is the growing need for reliable and efficient energy storage solutions in the telecommunications industry. With the rapid expansion of telecommunication networks and the increasing reliance on digital services, there is a critical need for backup power systems that can ensure uninterrupted operation during power outages or grid failures. AGM batteries offer superior performance, longer service life, and low maintenance requirements, making them an ideal choice for telecommunication applications.

Another significant market driver is the increasing adoption of renewable energy systems, such as solar and wind power installations. These systems often require energy storage solutions to store excess energy generated during peak production periods and release it during periods of high demand or low generation. AGM batteries are well-suited for these applications due to their deep-cycle capabilities, high energy density, and resistance to environmental factors.

The automotive industry is also a significant contributor to the demand for high-performance AGM batteries. These batteries are widely used in start-stop systems, which are designed to improve fuel efficiency and reduce emissions in modern vehicles. AGM batteries offer superior cranking performance, vibration resistance, and longer service life, making them a preferred choice for automotive applications.

Furthermore, the growing demand for reliable backup power systems in critical infrastructure, such as hospitals, data centers, and industrial facilities, is driving the market for high-performance AGM batteries. These applications require energy storage solutions that can provide uninterrupted power supply during emergencies or power outages, ensuring the continuity of essential operations.

Overall, the market demand for improving electrochemical performance of AGM batteries is expected to continue growing, driven by the increasing need for reliable and efficient energy storage solutions across various industries and applications.

Current State and Challenges of AGM Battery Technology

The current state and challenges of AGM (Absorbed Glass Mat) battery technology can be summarized as follows:

AGM batteries have gained widespread adoption in various applications, including automotive, marine, and renewable energy storage systems. These batteries offer several advantages over traditional flooded lead-acid batteries, such as improved safety, low maintenance requirements, and resistance to spillage. However, despite their advantages, AGM batteries still face several challenges that limit their performance and widespread adoption.

One of the primary challenges is the limited cycle life of AGM batteries compared to other advanced battery technologies, such as lithium-ion batteries. AGM batteries typically have a shorter lifespan, especially when subjected to deep discharge cycles or high-temperature environments. This limitation can be attributed to the degradation of the active materials and the gradual drying out of the glass mat separator over time.

Another challenge is the relatively lower energy density of AGM batteries compared to lithium-ion batteries. This limitation restricts their application in applications that require high energy density, such as electric vehicles or portable electronics. Additionally, AGM batteries have a higher self-discharge rate than lithium-ion batteries, which can lead to reduced capacity and shorter shelf life.

Furthermore, the manufacturing process of AGM batteries is more complex and costly compared to traditional flooded lead-acid batteries. The precise control of the glass mat compression and electrolyte absorption is crucial for optimal performance, which can increase production costs and quality control challenges.

Geographically, the development and adoption of AGM battery technology have been concentrated in regions with strong automotive and renewable energy industries, such as North America, Europe, and Asia-Pacific. However, the adoption rate in developing regions has been relatively slower due to cost considerations and the availability of alternative battery technologies.

Overall, while AGM batteries offer advantages in terms of safety and maintenance, their performance limitations and manufacturing challenges have hindered their widespread adoption in certain applications. Addressing these challenges through technological advancements and cost reductions will be crucial for the future growth and competitiveness of AGM battery technology.

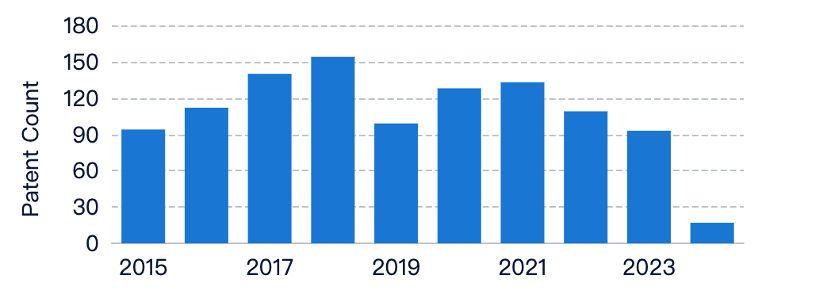

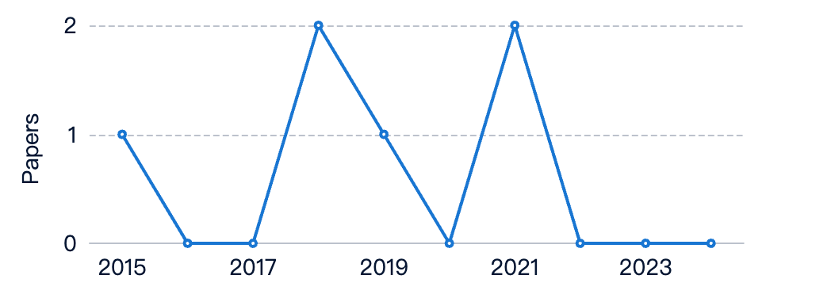

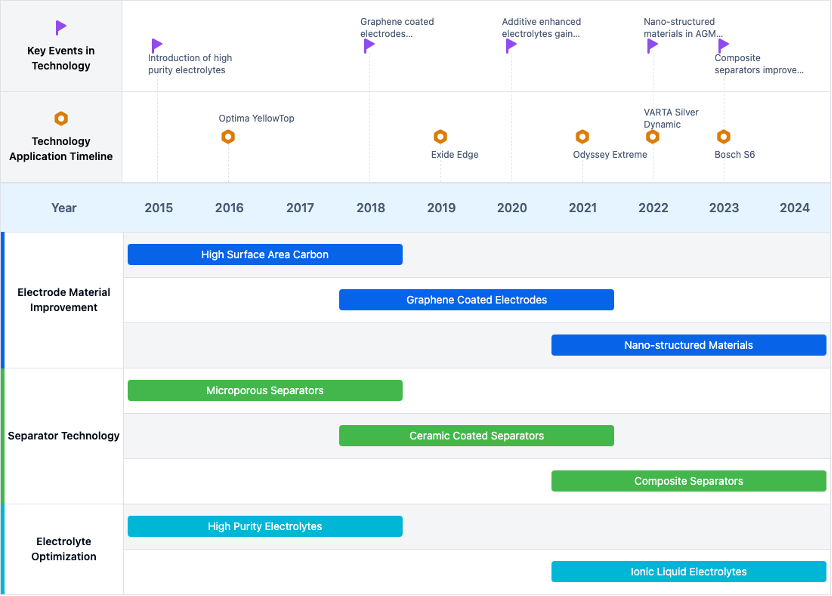

Evolution of AGM Battery Technologies

Existing Solutions for Enhancing AGM Battery Performance

AGM battery structure and components

The search results cover various aspects of AGM (Absorbed Glass Mat) battery structure and components, such as the AGM separator, electrode grids, battery containers, and electrolyte injection devices. These components play crucial roles in the performance and durability of AGM batteries.

- AGM battery plate group structure

- The search results cover various aspects related to the structure of the AGM battery plate group, including tight assembly structures, plate group compression mechanisms, and positioning/alignment features for the plates and separators. These structural elements aim to optimize the performance and durability of the AGM battery.

- AGM battery separator design

- Several search results focus on the design and materials used for the AGM battery separator, which plays a crucial role in electrolyte absorption and ion transport. Aspects covered include separator structures with through-holes, multi-layer separators, and separators with enhanced properties for high-temperature environments or vibration resistance.

- AGM battery formation and manufacturing processes

- The search results include various processes and techniques related to the formation and manufacturing of AGM batteries, such as internal formation processes, acid saturation detection methods, and equipment for acid injection, clamping, and grid collection during the manufacturing process.

- AGM battery structural components

- Several search results cover specific structural components of AGM batteries, including battery covers with exhaust functions, safety valve structures, handle designs, and clamping mechanisms for the plate group or grids.

- AGM battery performance testing and evaluation

- Some search results focus on methods and devices for testing and evaluating the performance of AGM batteries, such as techniques for detecting oxygen recombination efficiency, acid saturation levels, and air tightness during start-stop operation.

AGM battery manufacturing processes

Several search results focus on the manufacturing processes of AGM batteries, including acid filling methods, container formation processes, and separator production techniques. These processes can significantly impact the electrochemical performance and quality of AGM batteries.

AGM battery performance enhancement

Some search results discuss methods and materials for enhancing the performance of AGM batteries, such as using functional materials, improving heat resistance, and increasing charge acceptance. These advancements aim to improve the electrochemical performance and durability of AGM batteries.

AGM battery testing and evaluation

Several search results cover testing and evaluation methods for AGM batteries, including techniques for detecting acid saturation, measuring oxygen recombination efficiency, and assessing electrochemical performance. These methods are crucial for quality control and performance optimization.

AGM battery applications and specialized designs

The search results also include information on specific applications and specialized designs of AGM batteries, such as start-stop batteries for vehicles, high-vibration-resistant batteries, and batteries for parking air conditioners. These designs cater to the unique requirements of different applications.

Key Players in AGM Battery Industry

The competitive landscape for improving the electrochemical performance of AGM batteries is shaped by the industry’s current development stage, market size, and technology maturity. The industry is in a growth phase with increasing demand for high-performance energy storage solutions. The market size is expanding as applications in renewable energy and electric vehicles grow. In terms of technology maturity, companies like Fengfan Co., Ltd., Daramic LLC, Tianneng Battery Group Co., Ltd., Chaowei Power Group Co., Ltd., and EnPower, Inc. are at the forefront. These companies are investing heavily in R&D to enhance battery efficiency, longevity, and cost-effectiveness, indicating a competitive and rapidly evolving market.

Fengfan Co., Ltd.

Fengfan Co., Ltd. has developed an advanced AGM battery technology that focuses on enhancing the electrochemical performance through optimized grid design and improved electrolyte formulations. Their approach includes the use of high-purity lead and advanced carbon additives to increase battery life and efficiency.

Daramic LLC

Daramic LLC specializes in producing high-performance separators for AGM batteries. Their technology aims to improve the electrochemical performance by enhancing the separator’s porosity and electrolyte absorption capabilities. This results in better charge acceptance and longer cycle life.

Tianneng Battery Group Co., Ltd.

Tianneng Battery Group Co., Ltd. has introduced a series of AGM batteries with enhanced electrochemical performance. Their technology incorporates advanced grid alloys and high-density active materials to improve energy density and reduce internal resistance.

Chaowei Power Group Co., Ltd.

Chaowei Power Group Co., Ltd. focuses on improving the electrochemical performance of AGM batteries through innovative grid structures and optimized lead paste formulations. Their technology aims to enhance battery capacity and cycle life while maintaining cost-effectiveness.

EnPower, Inc.

EnPower, Inc. is working on next-generation AGM battery technology that leverages advanced materials and novel electrode designs to significantly boost electrochemical performance. Their research includes the use of nanomaterials and proprietary additives to enhance battery efficiency and longevity.

Core Innovations in AGM Battery Electrochemistry

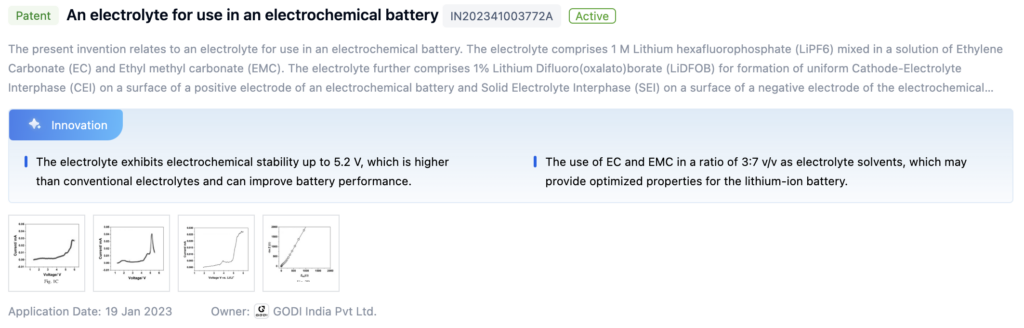

Patent1:An electrolyte for use in an electrochemical battery

Paper 1:Electrochemical performance of lithium-ion batteries

Potential Breakthroughs in AGM Battery Technology

- AGM battery separator materials and structures

- AGM battery formation and manufacturing processes

- Electrode materials and structures for AGM batteries

- Testing and monitoring devices for AGM batteries

Environmental Impact of AGM Battery Production

Regulatory Landscape for AGM Battery Manufacturing

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!