Technical Background and Objectives

Cabin air filters play a crucial role in maintaining a healthy and comfortable environment inside vehicles. They are responsible for removing pollutants, allergens, and other harmful particles from the air circulating within the cabin. However, over time, these filters can become clogged, reducing their effectiveness and potentially compromising the air quality inside the vehicle.

The stability of cabin air filters refers to their ability to maintain consistent performance over an extended period, ensuring that the air quality remains at an acceptable level throughout the filter’s lifespan. Improving the stability of these filters is a critical objective for automotive manufacturers and filter suppliers, as it directly impacts passenger comfort, health, and overall driving experience.

The primary goal of this research is to explore innovative solutions and technologies for improving the stability of cabin air filters, prolonging their effective lifespan and minimizing the need for frequent replacements. By achieving this objective, manufacturers can offer more reliable and cost-effective air filtration systems, while also reducing the environmental impact associated with frequent filter replacements.

Several factors contribute to the instability of cabin air filters, including exposure to varying environmental conditions, accumulation of contaminants, and degradation of filter materials over time. Addressing these challenges requires a multidisciplinary approach that combines advancements in materials science, filter design, and air flow dynamics.

Potential areas of investigation may include the development of advanced filter media with improved filtration efficiency and durability, innovative filter configurations that optimize air flow patterns, and the incorporation of self-cleaning or regenerative mechanisms to extend the filter’s operational life. Additionally, the integration of sensor technologies and predictive maintenance algorithms could enable real-time monitoring and proactive maintenance of cabin air filters, further enhancing their stability and performance.

Market Demand Analysis

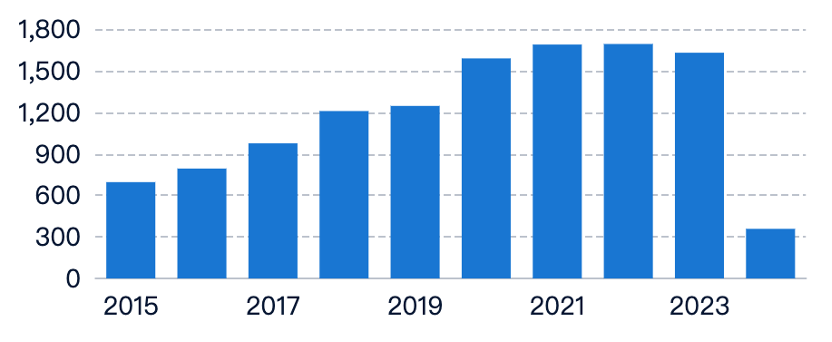

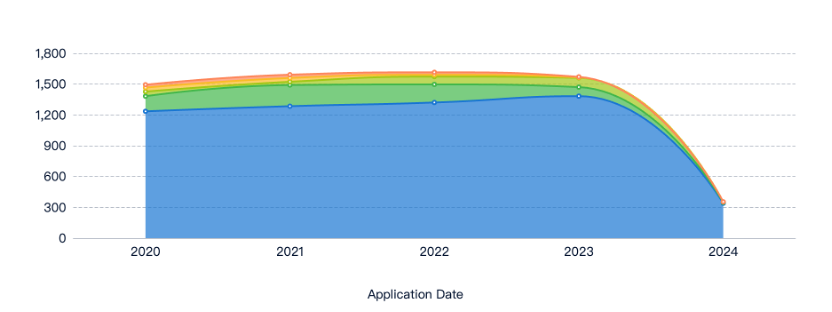

The market demand for cabin air filters is driven by several factors, including the growing awareness of air quality and its impact on health, the increasing number of vehicles on the road, and stricter regulations regarding vehicle emissions and air quality standards.

Firstly, the rising concern over air pollution and its detrimental effects on human health has led to a heightened demand for effective air filtration solutions, particularly in densely populated urban areas. Cabin air filters play a crucial role in removing harmful pollutants, allergens, and particulate matter from the air inside vehicles, providing a healthier and more comfortable environment for occupants.

Secondly, the global automotive industry has witnessed a steady growth in vehicle production and sales, leading to a larger number of vehicles on the road. As the vehicle population increases, the demand for cabin air filters, which are essential components in modern vehicles, also rises correspondingly.

Furthermore, governments and regulatory bodies around the world have implemented stricter emissions standards and air quality regulations to combat air pollution and promote environmental sustainability. These regulations often mandate the use of effective air filtration systems in vehicles, further driving the demand for high-performance cabin air filters.

In addition to the automotive sector, the demand for cabin air filters extends to other transportation industries, such as buses, trains, and aircraft, where maintaining clean and healthy air quality is equally important for passenger comfort and well-being.

Market analysts predict that the global cabin air filter market will continue to grow steadily in the coming years, driven by factors such as increasing vehicle production, stricter emissions regulations, and heightened consumer awareness of air quality issues. However, the market demand may also be influenced by factors such as economic conditions, technological advancements in air filtration systems, and changes in consumer preferences.

Overall, the market demand for cabin air filters is driven by the need for cleaner air, regulatory requirements, and the growing transportation sector, making it an important area for research and development to improve the stability and performance of these essential components.

Current State and Challenges

The stability of cabin air filters is a critical issue that affects the overall air quality and passenger comfort in vehicles. Currently, there are several challenges that hinder the development of more stable and efficient cabin air filters:

- Particulate matter variability: Cabin air filters are designed to capture a wide range of particulate matter, including dust, pollen, and soot. However, the composition and size distribution of these particles can vary significantly depending on factors such as geographic location, weather conditions, and traffic patterns. This variability makes it challenging to develop a one-size-fits-all solution for cabin air filters.

- Moisture and humidity: High levels of moisture and humidity can lead to the growth of mold and bacteria on cabin air filters, compromising their effectiveness and potentially introducing harmful contaminants into the cabin air. Maintaining filter performance under varying humidity conditions remains a significant challenge.

- Chemical contaminants: In addition to particulate matter, cabin air filters must also effectively remove gaseous pollutants and volatile organic compounds (VOCs) from the air. These chemical contaminants can originate from vehicle exhaust, industrial emissions, and even materials used in the vehicle’s interior. Developing filters that can efficiently capture a wide range of chemical contaminants without compromising airflow is a complex task.

- Filter clogging and pressure drop: Over time, cabin air filters can become clogged with accumulated particles, leading to a significant increase in pressure drop across the filter. This can reduce airflow and negatively impact the performance of the vehicle’s heating, ventilation, and air conditioning (HVAC) system. Balancing filter efficiency and pressure drop is a delicate trade-off that requires careful consideration.

- Filter replacement and maintenance: Cabin air filters require regular replacement to maintain their effectiveness. However, determining the optimal replacement interval can be challenging, as it depends on various factors such as driving conditions, filter design, and user behavior. Improper maintenance or failure to replace filters can lead to decreased air quality and potential health risks for occupants.

These challenges highlight the need for continued research and innovation in the field of cabin air filtration. Addressing these issues will require a multidisciplinary approach, involving advancements in filter materials, design, and manufacturing processes, as well as improved monitoring and maintenance strategies.

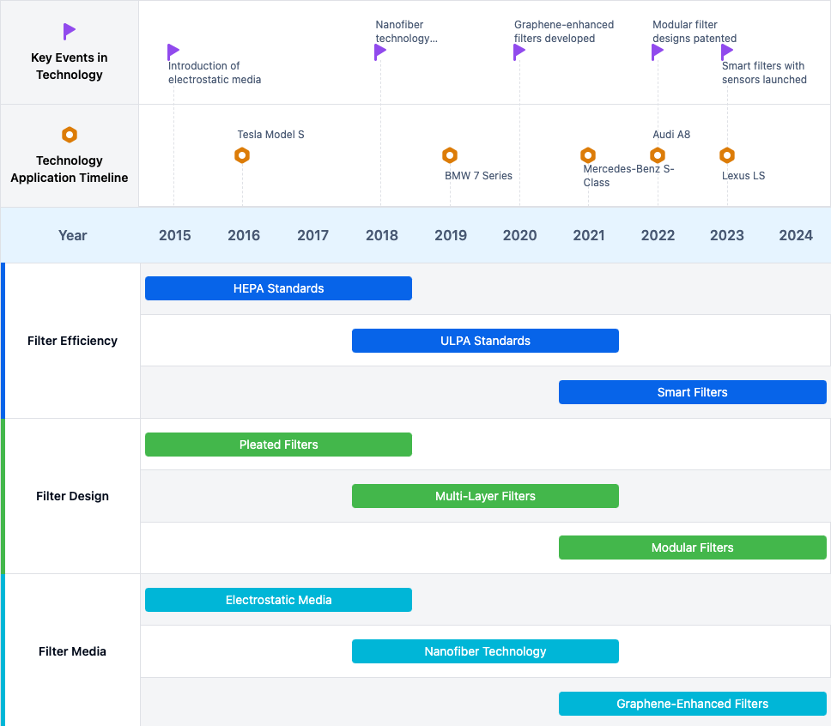

Technology Evolution Path

Current Technical Solutions

Cabin air filter structure and design

The cabin air filter structure and design play a crucial role in ensuring stability and efficient filtration. Various designs, such as modular filters, multi-stage filtration, and improved sealing mechanisms, have been developed to enhance the filter’s durability and prevent leakage or deformation.

- Cabin air filter structure and design

- The search results cover various aspects of cabin air filter structure and design, including filter housing, filter media, and mounting arrangements. These designs aim to improve air filtration efficiency, ease of installation, and maintenance.

- Cabin air filter materials and compositions

- Several search results focus on the materials and compositions used in cabin air filters, such as activated carbon, photocatalytic nanofibers, and antimicrobial filter media. These materials enhance the filter’s ability to remove pollutants, odors, and microorganisms.

- Cabin air filter monitoring and maintenance

- Some search results cover monitoring and maintenance aspects of cabin air filters, including filter usage detection, cleaning systems, and filter replacement indicators. These features help ensure optimal air quality and timely filter replacement.

- Cabin air filter integration with HVAC systems

- Several search results relate to the integration of cabin air filters with heating, ventilation, and air conditioning (HVAC) systems in vehicles. This includes filter placement, airflow control, and compatibility with HVAC components.

Filter media and materials

The choice of filter media and materials can significantly impact the stability and performance of cabin air filters. Antimicrobial filter media, activated carbon filters, and cold catalyst nets have been employed to improve filtration efficiency, adsorption capabilities, and resistance to microbial growth.

Filter monitoring and maintenance

Monitoring and maintaining cabin air filters is crucial for ensuring their stability and prolonged effectiveness. Systems and methods have been developed to monitor the condition of the filter, detect clogging or degradation, and facilitate timely replacement or cleaning.

Specialized cabin air filters

Specialized cabin air filters have been designed to address specific needs, such as air purification for aircraft cabins, excavator cabins, or negative pressure isolation environments. These filters are tailored to meet the unique requirements of different applications and operating conditions.

Filter integration and assembly

The integration and assembly of cabin air filters with other components, such as air conditioning systems or filter trays, can impact the overall stability and performance of the filtration system. Improved filter assemblies and installation methods have been developed to ensure proper sealing and secure mounting.

Key Players Analysis

The competitive landscape for the issue of improving the stability of cabin air filters can be analyzed through the industry’s development stage, market size, and technology maturity. The industry is currently in a growth phase with increasing demand for advanced air filtration systems in aviation. The market size is expanding as airlines and aircraft manufacturers prioritize passenger health and safety. In terms of technology maturity, Beihang University and Zhuhai Xiang Yi Aviation Technology Co., Ltd. are leading in research and innovation. Gulfstream Aerospace Corp. and The Boeing Co. are integrating advanced filtration technologies into their aircraft, while Xinxiang Bashan Precision Filter Co. Ltd. focuses on precision manufacturing of high-quality filters.

Beihang University

Beihang University has developed advanced air filtration systems focusing on nanofiber technology. Their solution aims to enhance the stability and efficiency of cabin air filters by using electrospun nanofibers, which provide high filtration efficiency and low pressure drop.

Zhuhai Xiang Yi Aviation Technology Co., Ltd.

Zhuhai Xiang Yi Aviation Technology Co., Ltd. offers a multi-layered filtration system that integrates activated carbon and HEPA filters. This system is designed to improve air quality and stability by effectively removing particulate matter and volatile organic compounds.

Gulfstream Aerospace Corp.

Gulfstream Aerospace Corp. utilizes a proprietary air purification system that combines HEPA filters with UV-C light technology. This dual approach aims to enhance the stability and cleanliness of cabin air by eliminating airborne pathogens and allergens.

Xinxiang Bashan Precision Filter Co. Ltd.

Xinxiang Bashan Precision Filter Co. Ltd. specializes in high-efficiency particulate air (HEPA) filters designed for aviation applications. Their filters are engineered to provide stable and reliable air quality by capturing fine particles and ensuring minimal airflow resistance.

The Boeing Co.

The Boeing Co. has implemented an advanced air filtration system that incorporates both HEPA and carbon filters. Their solution focuses on maintaining air quality and stability by removing a wide range of contaminants, including particulates and odors.

Key Technology Interpretation

Patent1:Indoor air purification equipment with high stability

Paper 1:Impact of the Carbon Nanofillers Addition on Rheology and Absorption Ability of Composite Shear Thickening Fluids

Potential Innovation Directions

- Cabin air filter structure and design

- Cabin air filter materials and compositions

- Cabin air filter monitoring and control systems

- Cabin air filter integration and installation

Regulatory and Environmental Factors

Future Trends in Cabin Air Filters

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!