Thermal Resistance Goals for Borosilicate Glass

Enhancing the thermal resistance of borosilicate glass is crucial for industries like scientific glassware, cookware, and high-temperature applications. Objectives include:

- Increasing Softening Point: Allowing the glass to withstand higher temperatures without deformation.

- Enhancing Thermal Shock Resistance: Enabling the glass to endure sudden temperature changes without cracking.

- Reducing Thermal Expansion: Minimizing the risk of cracking or deformation due to thermal stresses.

- Improving High-Temperature Stability: Ensuring the glass maintains its properties at elevated temperatures.

To get a detailed scientific explanations of borosilicate glass, try Eureka.

Market Demand for High-Temperature Resistant Glass

High-temperature resistant glass is increasingly needed due to advancements in various sectors:

- Energy and Power Generation: Essential in power plants and high-efficiency coal-fired power plants.

- Aerospace and Automotive Industries: Required for aircraft windshields, engine components, and exhaust systems.

- Chemical and Metallurgical Processes: Used in furnaces, reactors, and smelters.

- Laboratory Equipment: Crucibles, test tubes, and reaction vessels for high-temperature research.

- Consumer Electronics and Household Appliances: Oven doors, halogen lamps, and high-end display screens.

Current State and Challenges in Borosilicate Glass

Despite its benefits, borosilicate glass faces challenges:

- Thermal Shock Resistance: Less resistant compared to specialized glass types.

- High Manufacturing Cost: Due to the addition of boron oxide.

- Geographical Production Concentration: Primarily in Europe and Asia, leading to supply chain issues.

- Chemical Susceptibility: Vulnerable to certain aggressive chemicals like hydrofluoric acid.

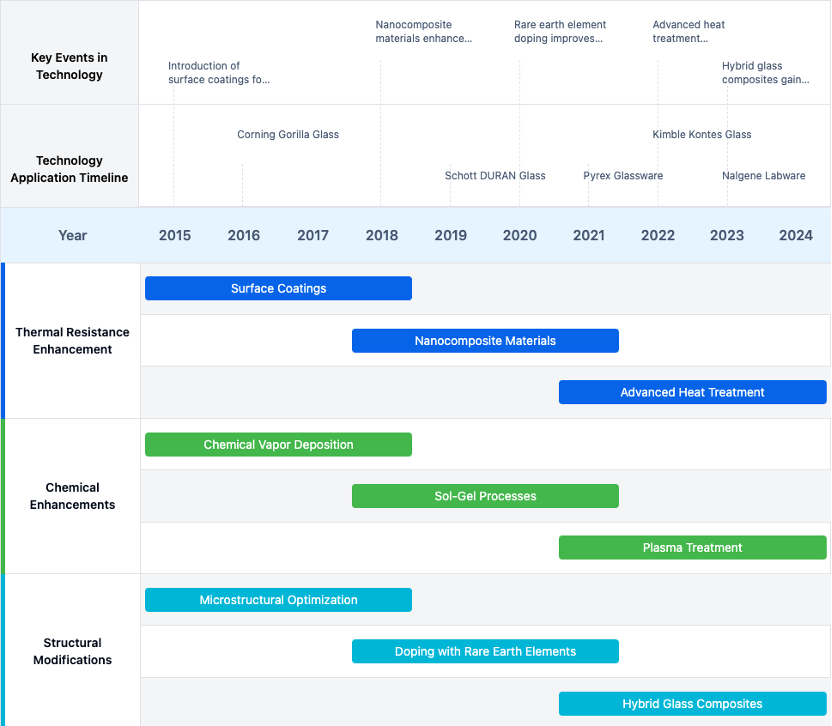

Evolution of Thermal Resistant Glass Technologies

Existing Solutions for Enhancing Thermal Resistance

Borosilicate Glass Compositions

- High Strength Compositions: Adjusting ratios of silica, boron oxide, and additives.

- High Boron Oxide Content: Enhances chemical and thermal properties.

- Optimized Alkali Content: Balancing chemical durability and workability.

- Added Reinforcing Agents: Alumina, zirconia, or other oxides for improved strength.

- Controlled Thermal Expansion: Minimizing thermal stresses.

- Improved Chemical Resistance: Optimizing the ratio of network formers to network modifiers.

Chemical Strengthening Methods

- Ion Exchange or Thermal Tempering: Creating compressive surface stresses.

- Suitable Compositions: Specific amounts of SiO2, B2O3, Al2O3, and alkali metal oxides.

- Continuous and Flexible Processes: Strengthening thin or flexible glass substrates.

High-Temperature Applications

- Specialized Compositions: For solar energy devices, microwave ovens, and furnaces.

- Preparation Methods: Specific melting and annealing processes with additives or dopants.

Low-Boron Borosilicate Glass

- Reduced Boron Content: Improves UV transparency, chemical resistance, and thermal stability.

- Controlling Boron Volatilization: Techniques to minimize loss during high-temperature melting.

Foam and Porous Materials

- Lightweight and High-Strength Foam Glasses: For thermal insulation, filtration, and catalysis.

Key Players in Borosilicate Glass Industry

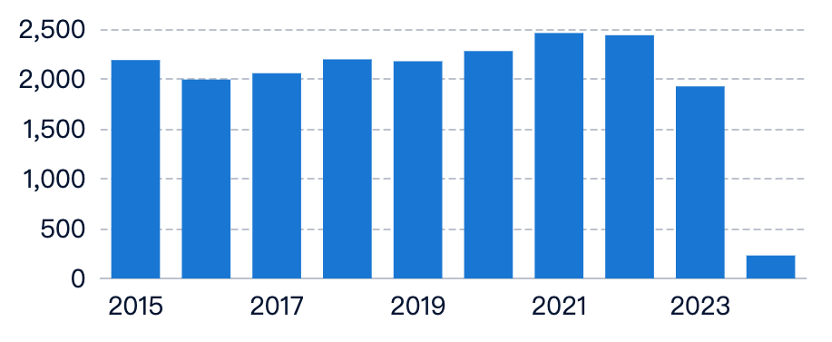

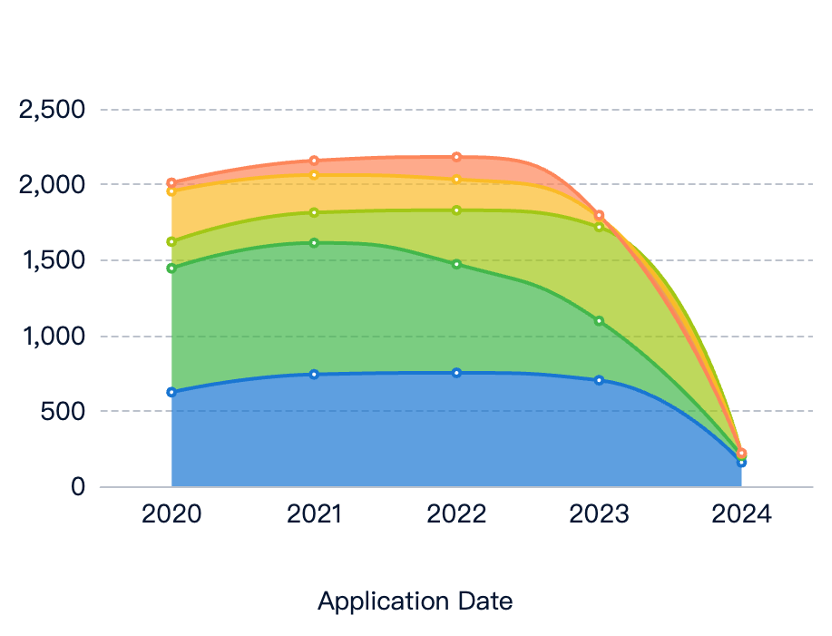

Semiconductor Energy Laboratory Co. Ltd.

- Patents: 2234 patents on borosilicate glass strength.

- Focus: Advanced compositions and manufacturing processes for thermal resistance.

Tianjin University

- Publications: 20 on composite materials, additives, and coatings.

- Focus: Advanced composites and reinforced glass products.

Kyocera Corp.

- Patents: 1492 related to borosilicate glass strength.

- Focus: Innovative materials and processes for various applications.

Imperial College London

- Publications: 17 on composite materials and reinforcing agents.

- Focus: Advanced composites and interfacial properties.

Core Innovations in Glass Strengthening

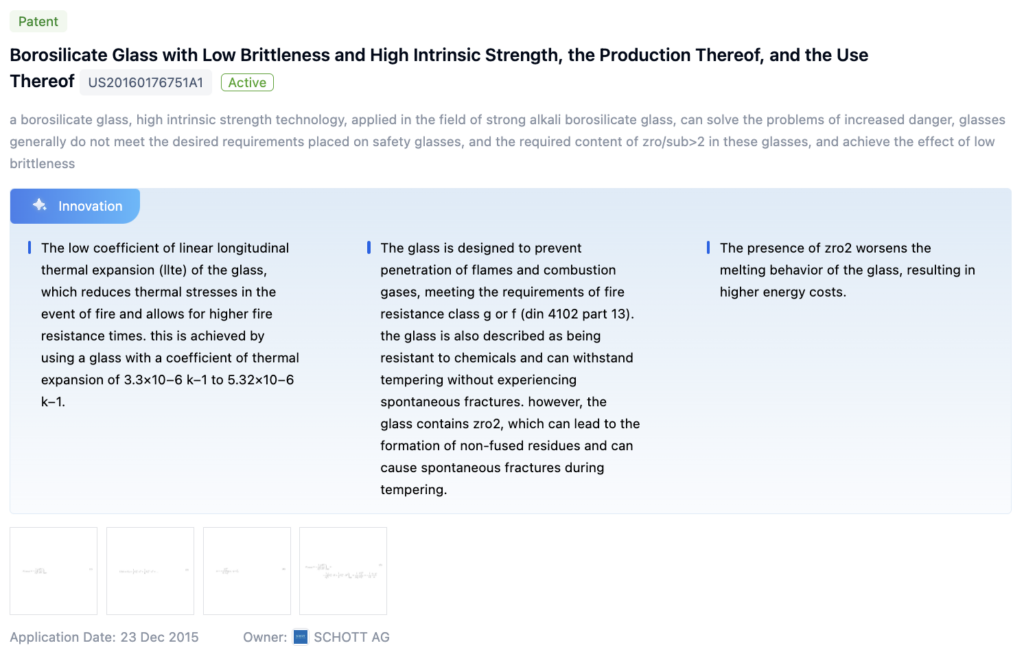

Patent 1: Borosilicate Glass with Low Brittleness and High Intrinsic Strength

- Core Points:

- Low coefficient of linear longitudinal thermal expansion (LLTE).

- Fire resistance and chemical durability.

- Presence of ZrO2 for enhanced properties but may increase energy costs.

Patent 2: White Jade Color High Borosilicate Glass

- Core Points:

- Unique composition for white jade-like appearance.

- High refractive index and light transmission.

- Specific ratio of coloring agents for stability.

Paper 1: Alumino-Borosilicate Glass Properties

- Core Points:

- Higher softening point temperature (~800°C).

- Excellent heat resistance and thermal shock resistance.

- Low coefficient of thermal expansion.

Potential Breakthroughs in Thermal Resistance

- High Thermal Resistance Compositions: For extreme temperature changes.

- High Chemical Resistance: For environments with harsh chemicals.

- Low Thermal Expansion: For precision optics and scientific instruments.

- Enhanced Mechanical Properties: For impact and scratch resistance.

Regulatory Landscape for High-Temperature Glass

Regulatory bodies such as the FDA, EC, and ISO establish guidelines for safety and quality. Compliance with standards like CFR Title 21, REACH, and ISO 3585 ensures material safety, performance, and environmental responsibility. Failure to adhere to these regulations can result in legal consequences, product recalls, and reputational damage.

Environmental Impact of Borosilicate Glass Production

Energy Consumption:

- High temperatures required for production.

Greenhouse Gas Emissions:

- CO2 emissions from fuel combustion.

Waste Generation:

- Solid waste, air emissions, and wastewater.

Water Consumption:

- Significant water use in production.

Raw Material Extraction:

- Environmental impacts from mining.

Mitigation Strategies:

- Energy-efficient technologies.

- Recycling and reusing waste materials.

- Renewable energy sources.

- Responsible raw material sourcing.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!