Technical Background and Objectives

Background

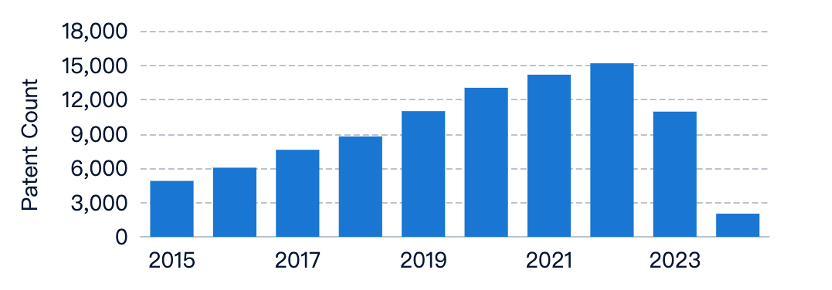

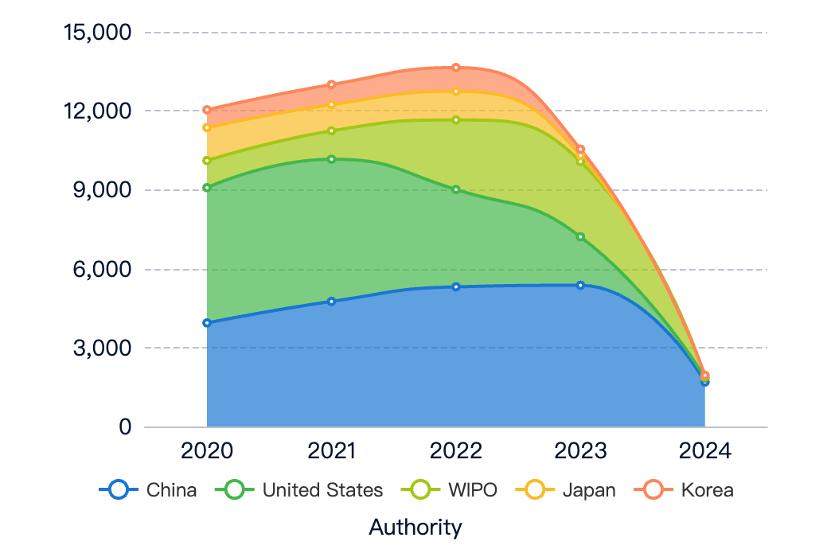

The technical effect of ‘Function increase’ in industrial robots has been a major focus area as evidenced by the consistent year-over-year increase in patent applications. This indicates sustained innovation and research efforts aimed at enhancing the functionality of industrial robots, driven by market demand and technological advancements. In contrast, literature publications show initial fluctuations, a subsequent surge, and then a decline, possibly reflecting the transition from foundational research to applied research and commercialization.

Objectives

The primary objective is to enhance the functionality of industrial robots, enabling them to perform a broader range of tasks with greater efficiency and precision. This research aims to develop solutions that will revolutionize industrial robot operations, increase productivity, reduce operational costs, and improve overall competitiveness in the manufacturing sector.

To get a detailed scientific explanations of Industrial Robots, try Eureka.

Technical Current Status Analysis

Industrial Robots Overview

Industrial robots are crucial in modern manufacturing, enhancing production efficiency, quality, and safety. The demand for increasing functionality of industrial robots is growing rapidly across various industries:

- Automotive Industry: Used for welding, painting, and material handling. Increased functionality is needed for handling complex assembly processes and stringent quality requirements.

- Electronics Industry: Used for circuit board assembly and product testing. Robots with improved vision systems and higher precision are essential.

- Food and Beverage Industry: Used for packaging and palletizing. Robots with greater flexibility and faster changeover times are in demand.

- Logistics and Warehousing: Used for order picking and sorting. Enhanced mobility and navigation capabilities are required.

Technical Characteristics and Challenges

- Dexterity and Precision: Enhanced dexterity and precision are needed for complex tasks.

- Sensor Integration and Perception: Advanced sensors and robust perception algorithms are essential.

- Mobility and Navigation: Robust navigation systems and efficient path planning are crucial.

- Flexibility and Adaptability: Robots must handle diverse tasks and configurations.

- Human-Robot Collaboration: Intuitive interfaces, safety systems, and seamless collaboration with human operators are necessary.

Technological Paths

- Advanced Mechatronic Design: Innovative mechanical designs, lightweight materials, and high-performance actuators.

- Artificial Intelligence and Machine Learning: Improved perception, decision-making, and adaptive control.

- Sensor Fusion and Multi-Modal Perception: Robust perception and environmental understanding.

- Collaborative Robotics: Safe and intuitive human-robot collaboration systems.

- Mobile Robotics and Autonomous Navigation: Efficient navigation and mobility in dynamic environments.

- Modular and Reconfigurable Systems: Flexible and scalable robotic systems.

Research Content

Research Objectives

Enhance the functionality of industrial robots, enabling them to perform a broader range of tasks with greater efficiency and precision.

Research Direction and Focus

Advanced Sensing and Perception

- Explore advanced sensor technologies (vision systems, tactile sensors, depth cameras).

- Investigate machine learning algorithms and computer vision techniques for intelligent decision-making and adaptive behavior.

Intelligent Control and Automation

- Develop advanced control algorithms (reinforcement learning, optimization techniques, adaptive control strategies).

- Integrate AI and machine learning for real-time learning, movement optimization, and intelligent decision-making.

Human-Robot Collaboration and Interaction

- Develop intuitive and natural interfaces (gesture recognition, voice commands, augmented reality).

- Investigate safety protocols, communication strategies, and task allocation methods for efficient and secure human-robot collaboration.

Technical Development Roadmap

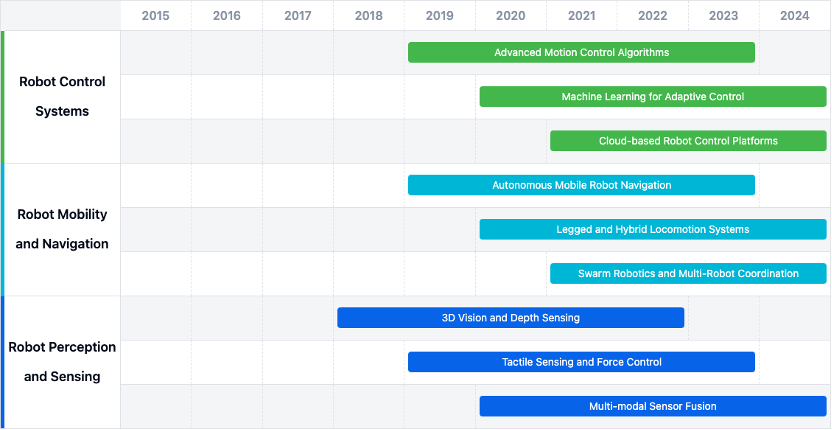

Key Areas of Advancement

- Robot Control Systems: Advanced motion control algorithms, machine learning techniques, and cloud-based platforms.

- Robot Perception and Sensing: 3D vision, depth sensing, tactile sensing, force control, and multi-modal sensor fusion.

- Robot Mobility and Navigation: Autonomous navigation, legged and hybrid locomotion, and swarm robotics.

Main Player Analysis

Key Players and Focus

- Samsung Electronics Co., Ltd.: Advanced robotic systems for manufacturing and automation, focusing on dexterity, precision, and adaptability.

- QUALCOMM Inc.: Enhancing functionality through wireless communication, sensor fusion, and machine learning algorithms.

- LG Electronics Inc.: High-precision assembly, automated material handling, and flexible manufacturing processes.

- Hannover Medical School: Medical robotics and biomechanics contributing to advancements in industrial robotics.

- Shanghai Jiao Tong University: Adaptive control, cloud robotics, and intelligent manipulation systems.

Current Technical Solution Overview

Adding New Functions to Industrial Robots

- Software Upgrades: Improved monitoring, control, and automation capabilities.

- Hardware Enhancements: Additional sensors, actuators, and mechanical components.

- Programming and Control: Improved user interfaces, programming languages, and control algorithms.

- System Integration: Connecting robots to other systems or devices for coordinated operations and data exchange.

Robot Control Methods and Systems

- Enhanced Functionality: Advanced control algorithms, sensor integration, and communication interfaces.

- Calibration and Programming: Techniques for calibrating and programming robots for better performance.

- Adaptive Control: Methods for adaptive and intelligent control based on environmental conditions and learned models.

Industrial Robot Systems and Configurations

- System Configurations: Control systems, communication interfaces, and safety features.

- Programming Methods: Lead-through programming, collaborative operation, and performance analysis.

- Applications and Tasks: Object manipulation, laser processing, and cooperative operations.

Robot Programming and Motion Planning

- Manual Guidance: Intuitive programming through manual guidance.

- Off-line Programming: Simulating and programming in a virtual environment.

- Motion Planning Algorithms: Efficient and optimized path planning and collision avoidance.

- User Interfaces: Graphical programming tools and integrated development environments.

Robot Performance Analysis and Optimization

- Performance Analysis: Techniques for measuring and assessing speed, accuracy, repeatability, and efficiency.

- Optimization Techniques: Enhancing speed, precision, and capabilities through control systems and structural modifications.

- Testing and Validation: Methods for testing and validating robot performance.

- Human-Robot Interaction: Analyzing and optimizing performance in collaborative environments.

Key Patent Interpretation

Patent Highlights

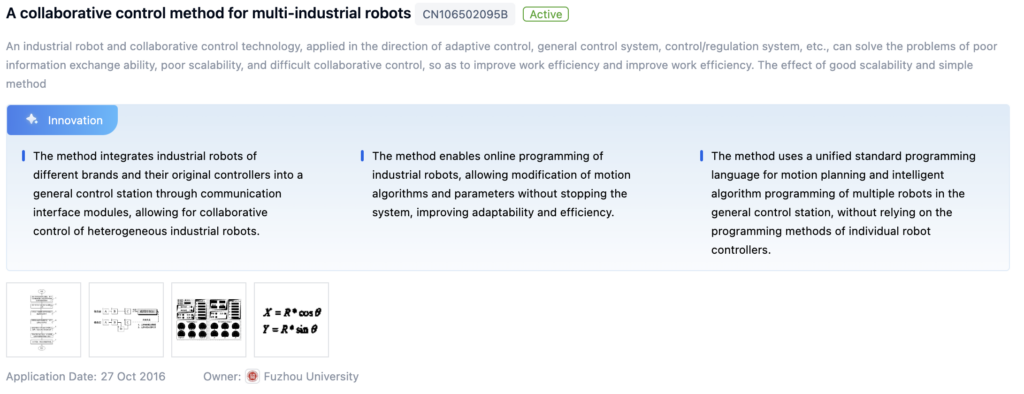

Patent 1: Collaborative Control Method for Multi-Industrial Robots

- Core Invention Points:

- Integrates different brands of robots into a general control station for collaborative control.

- Enables online programming for adaptability and efficiency.

- Uses a unified standard programming language for multiple robots.

Patent 2: Automated Configuration of Monitoring Function for Industrial Robots

- Core Invention Points:

- Synchronizes monitoring function with processing steps in a CAM environment.

- Automates configuration to reduce human errors.

Patent 3: Image Analysis Method for Determining Rotational Position and Classification of Objects

- Core Invention Points:

- Divides binary image regions into sub-regions and evaluates their positions and features.

- Uses centroids, contour lines, and angles for accurate classification.

Possible Research Directions

- Adding New Functionalities to Industrial Robots: Enhancing capabilities with new functions or features.

- Control Systems and Methods for Industrial Robots: Improving control and programming accuracy and flexibility.

- Industrial Robot Systems and Integration: Streamlining and optimizing industrial processes.

- Programming and Adjustment of Industrial Robot Movements: Enhancing precision and ease of programming.

- Energy Efficiency and Performance Analysis: Reducing energy consumption and optimizing performance.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!