Graphene Oxide Development and Goals

Graphene oxide (GO) is a derivative of graphene, known for its high specific surface area, excellent mechanical strength, and versatile chemical functionality. The pursuit of a large specific surface area in GO is driven by applications in energy storage, catalysis, and environmental remediation. A higher surface area enhances chemical reactions, adsorption capacity, and charge storage capabilities.

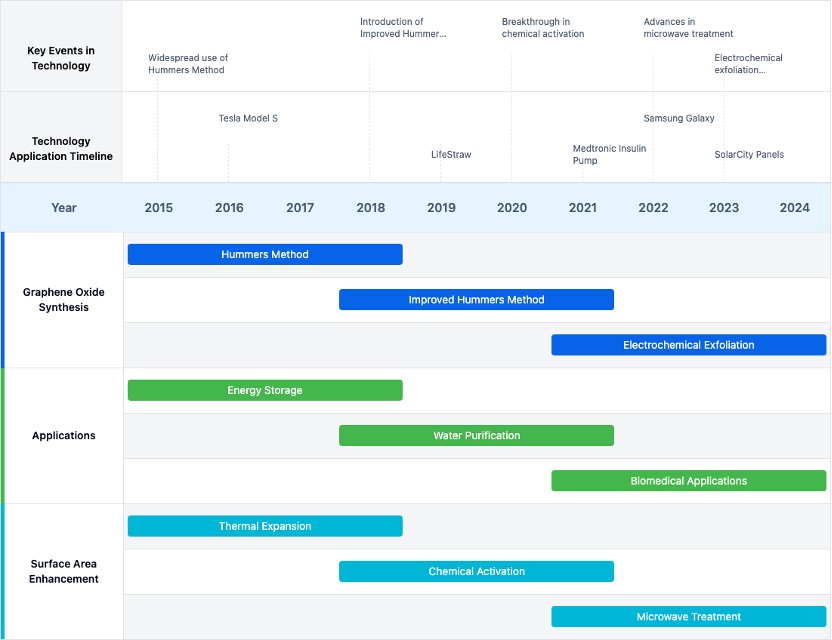

Development has progressed from early mechanical and chemical exfoliation methods to advanced techniques like chemical vapor deposition (CVD) and electrochemical exfoliation, resulting in GO with fewer defects and higher surface areas. Ongoing research focuses on optimizing synthesis, preventing restacking, and integrating GO with other nanomaterials to enhance surface area and functionality.

To get a detailed scientific explanations of Graphene Oxide, try Eureka.

Market Demand for Graphene Oxide Applications

GO’s unique properties drive its market demand across various industries:

- Energy Storage: GO improves electrode performance in lithium-ion batteries and supercapacitors.

- Water Treatment: Effective adsorbent for pollutants and excellent membrane material for purification.

- Biomedical: Used in drug delivery systems, biosensors, and tissue engineering due to its biocompatibility.

- Electronics and Optoelectronics: Ideal for transparent conductive films, flexible displays, and high-performance devices.

The market demand for GO is expected to grow with ongoing research and cost-effective production methods.

Current State and Challenges of Graphene Oxide

GO technology faces several challenges:

- Standardized Production: Lack of consistent, scalable methods for high-quality GO.

- Surface Area Control: Reducing restacking and optimizing surface area.

- Stability and Dispersion: Preventing aggregation in various solvents and matrices.

- Regional Disparities: Research and commercialization vary globally, with leaders in North America, Europe, and Asia.

Research focuses on new synthesis methods, surface modification, and innovative processing strategies to overcome these challenges.

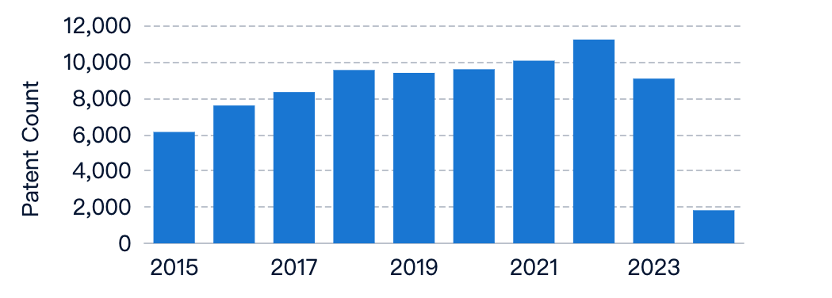

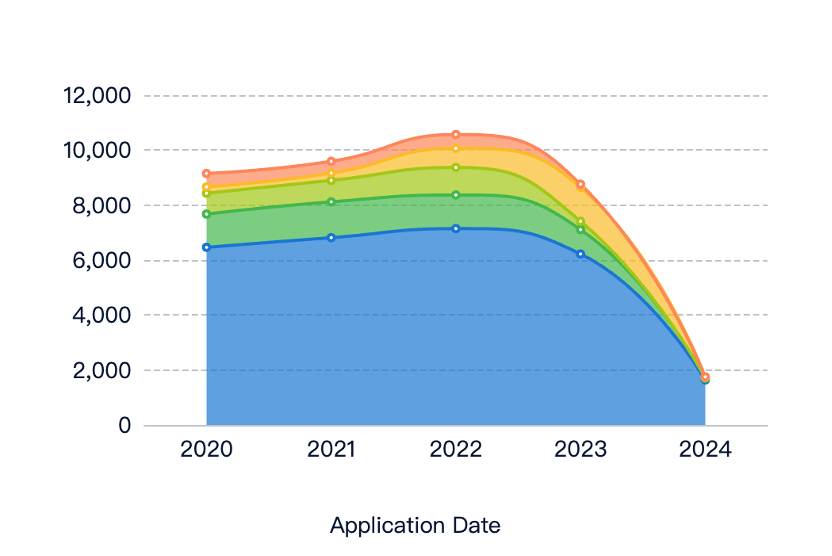

Evolution of Graphene Oxide Technologies

A detailed study of the historical progress and new advancements in techniques to enhance the specific surface area of GO.

Existing Solutions for Graphene Oxide Synthesis

Preparation Methods

- Microwave-Assisted: Rapid preparation using microwave radiation for high surface area.

- Low-Temperature Thermal Expansion: Produces highly porous graphene through thermal treatment.

- Aerogel-Based: Sol-gel processes followed by drying to preserve porous structure.

- Template-Assisted: Using sacrificial materials to create porous graphene.

- Large-Area Synthesis: Techniques like CVD for large-area films and sheets.

Synthesis Techniques

- Chemical Oxidation: Produces GO with high specific surface area.

- Electrochemical Methods: Controlled synthesis for high surface area.

- Template Methods: Creating porous structures with high surface area.

Composites

- With Metal Oxides: Enhanced adsorption and catalytic activity.

- With Polymers: Improved mechanical and thermal properties.

- With Carbon Materials: Enhanced electrical conductivity and thermal stability.

Surface Modification

- Chemical Reactions: Introducing functional groups to enhance properties.

- Coatings: Adding protective or functional layers.

- Nanoparticles: Incorporating nanoparticles for specific applications.

Characterization Techniques

- BET Surface Area Analysis: Measuring specific surface area.

- Spectroscopy and Microscopy: Analyzing functional groups and structural features.

Key Players in Graphene Oxide Industry

Chinese Academy of Sciences

Focus on environmental remediation, gas sensing, and energy storage.

Semiconductor Energy Laboratory Co. Ltd.

Specializes in electronic devices and energy storage systems.

Samsung Electronics Co. Ltd.

Research on electronic components and energy storage devices.

Contemporary Amperex Technology Co. Ltd.

Emphasizes high-performance lithium-ion batteries.

University of Jinan

Research on biosensing, environmental remediation, and energy storage.

Core Innovations in Graphene Oxide Research

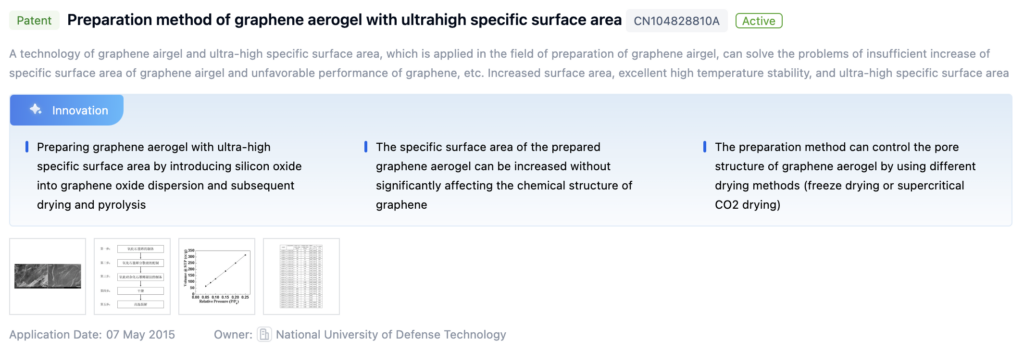

Patent 1: Preparation Method of Graphene Aerogel with Ultrahigh Specific Surface Area

- Core Invention Points:

- Introduces silicon oxide into GO dispersion.

- Controls pore structure through different drying methods.

Patent 2: High Specific Surface Area of Silicon Oxide Hybridized Graphene Aerogel

- Core Invention Points:

- Combines GO and siloxane for high surface area.

- Controls pore size distribution using liquid mixing.

Paper 1: Measuring the Specific Surface Area of Monolayer Graphene Oxide in Water

- Core Invention Points:

- Rheology-based method to measure specific surface area.

- Achieves a value close to theoretical predictions.

Paper 2: On the Chemical Reduced Large Specific Surface Area Graphene Oxide

- Core Invention Points:

- Prepares graphene sheets with high capacity and good cycling stability for lithium-ion batteries.

Potential Breakthroughs in Graphene Oxide Applications

Preparation Methods

- Large-Area Films: Techniques like esterification reactions and roll-to-roll synthesis.

- High Specific Surface Area Materials: Chemical oxidation and electrochemical methods.

- Enhanced Properties Composites: Combining GO with metal oxides, carbon nanotubes, or polymers.

Surface Modification

- Chemical Functionalization: Adding functional groups or nanoparticles.

- Purification and Reduction: Obtaining high-quality GO and reduced GO (rGO).

Environmental Impact of Graphene Oxide Production

GO production involves strong oxidizing agents, creating hazardous waste. Environmental impact includes:

- Hazardous Waste: Containing heavy metals and acidic compounds.

- Safety Hazards: For workers handling strong oxidizing agents.

- Environmental Release: Potential impact on ecosystems.

Mitigation strategies include using environmentally friendly oxidizing agents, effective waste treatment, solvent recycling, and closed-loop systems.

Regulatory Landscape for Graphene Oxide Usage

The regulatory framework for GO is evolving, with guidelines varying by region:

- United States (EPA and OSHA): Regulates nanomaterials under TSCA and workplace exposure.

- European Union (REACH): Requires registration and safety data sheets.

- Other Regions: Canada, Australia, and Japan have their own regulatory frameworks.

Staying informed and complying with relevant regulations is crucial for safe and responsible development and use of GO.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!