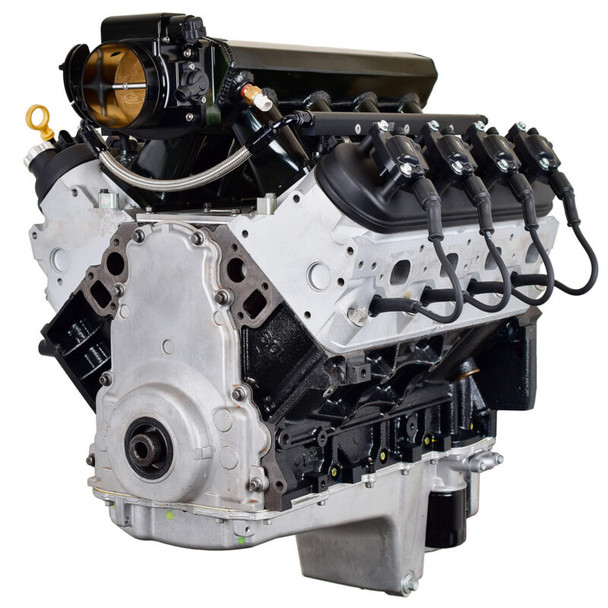

Introduction to the LQ4 Engine

The LQ4 engine is a 6.0L V8 engine from General Motors, part of the Gen III small-block engine family. Initially introduced in 2001, this engine has become popular in both factory applications and the aftermarket scene. Known for its durability, strong performance, and tuning potential, the LQ4 has found its place in a wide range of vehicles, including trucks, SUVs, and custom builds. This article will explore the key features, performance capabilities, and popular modifications of the LQ4 engine, helping you understand why it remains a sought-after powerplant for automotive enthusiasts.

Key Specifications: Horsepower, Torque, and Fuel Efficiency

- Horsepower

The LQ4 is capable of producing up to 464 horsepower in a budget rebuild. This power makes it a strong choice for applications that demand significant performance. - Torque

A standout feature of the LQ4 is its impressive torque. The engine delivers substantial torque, which is essential for tasks like towing and hauling. The torque curve ensures smooth power delivery, even under heavy loads. - Fuel Efficiency

Although the LQ4 is built for power and durability, it still maintains reasonable fuel efficiency. Modifications like a torquey cam can improve fuel mileage by optimizing power delivery and reducing downshifting on inclines. However, some performance upgrades may affect fuel efficiency.

Performance and Applications of the LQ4 Engine

- Performance Specifications:

The LQ4 produces 346 horsepower and delivers 380 lb-ft of torque, making it ideal for heavy-duty applications. Its large bore size enhances power output and overall performance. - Applications:

The LQ4 is versatile and can be used in various applications, from heavy-duty trucks to performance modifications. It is designed for vehicles that need both power and reliability.

Additionally, the LQ4 can be upgraded or modified for better performance. For those seeking more power, the LQ9 version offers enhanced performance.

LQ4 Engine vs. LQ9: Key Differences and Similarities

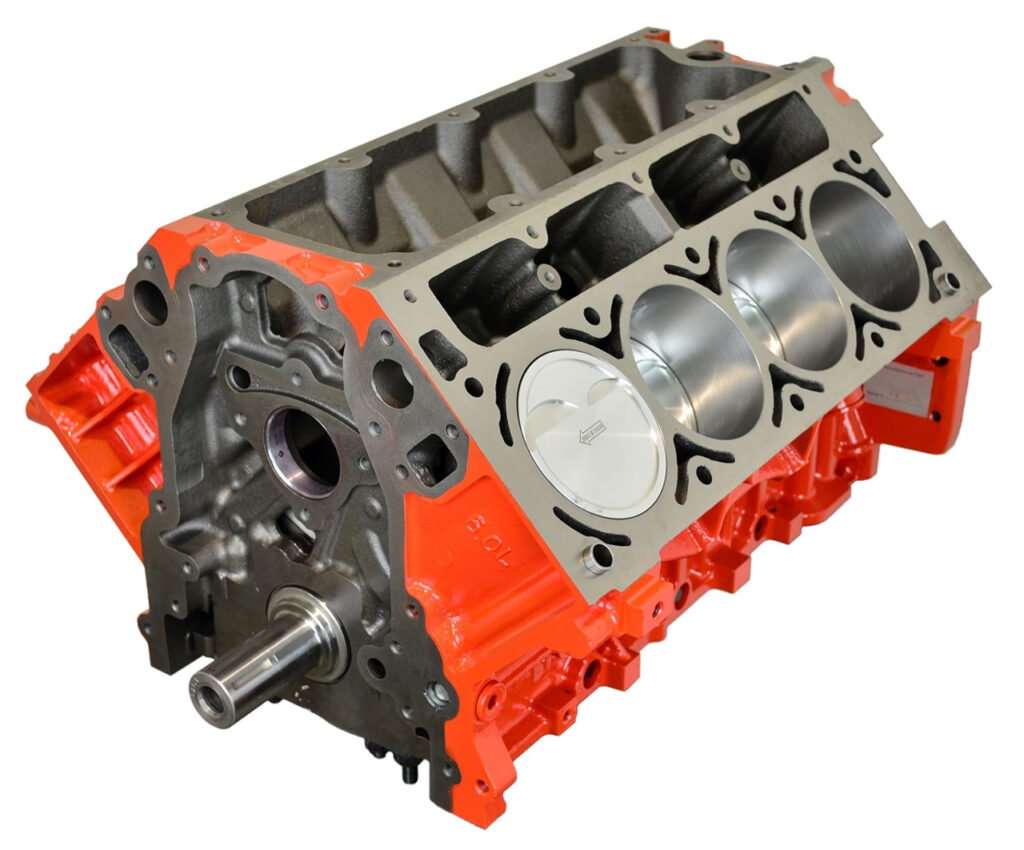

- Block Design

The LQ4 and LQ9 engines differ mainly in their pistons and camshaft designs. The LQ9 uses flat-top pistons, which offer higher compression than the dished pistons in the LQ4. This design difference contributes to the LQ9’s slight increase in horsepower and torque. - Performance

The LQ9 typically delivers about 10 more horsepower and 10 lb-ft of torque than the LQ4. This is due to its higher compression ratio and improved airflow characteristics. As a result, the LQ9 is a popular choice for those seeking a performance boost. - Compression Ratio

The LQ9’s flat-top pistons provide a higher compression ratio, enhancing fuel efficiency and performance, especially under load. In contrast, the LQ4’s dished pistons result in a lower compression ratio, which can affect performance at higher RPMs. - ECU and Wiring

Differences in the Engine Control Module (ECM) tuning and wiring harness between the LQ4 and LQ9 can impact engine management. These variations can affect the engine’s performance and drivability. - Sound

Some users note that the LQ9 engine produces a different sound compared to the LQ4. However, this is subjective and can depend on factors like exhaust systems and modifications. - Applications

Both engines are commonly used in trucks and SUVs. The LQ9 is typically found in higher trim levels or performance-oriented models, while the LQ4 is often used in base models.

Popular Upgrades and Modifications for the LQ4 Engine

LS3 Heads and Intake Installation

Installing LS3 heads and intake is a popular upgrade for LQ4 and LQ9 engines. These components, compatible with any LS block with a minimum 4.000 in. bore, can boost performance. They improve airflow and combustion efficiency, leading to increased power output.

Camshaft and Injector Upgrades

Upgrading the camshaft and injectors can enhance engine performance significantly. For instance, using 42 lbs injectors and a camshaft like the T70 can improve torque and quick spool-up. However, at higher RPMs, the performance may start to taper off.

Internal Improvements and Power Adders

Consider both internal upgrades and power adders to take your engine to the next level. Basic bolt-ons are a good start, but turbocharging or supercharging can drastically boost power and performance.

Rebuilding for Performance

A rebuild focused on performance can yield impressive results. Using flat-top pistons for better compression, along with a careful selection of components, can push the engine to around 464 horsepower. Proper tuning ensures that the engine performs optimally.

Maintenance and Longevity Tips for the LQ4 Engine

- Regular Oil Changes

Follow the manufacturer’s recommended oil change schedule. Using high-quality oil and filters reduces engine wear and helps maintain smooth performance. - Coolant Maintenance

Check and replace coolant regularly to prevent overheating and corrosion. A well-maintained cooling system is essential for engine longevity. - Air Filter Replacement

Replace the air filter regularly to ensure a clean air supply. This improves engine performance and fuel efficiency. - Spark Plug Maintenance

Replace spark plugs as per the recommended interval. This ensures proper ignition and prevents misfires, helping the engine run smoothly. - Fuel System Care

Keep the fuel system clean by using additives and replacing the fuel filter when needed. This prevents injector clogging and ensures efficient combustion.

To get detailed scientific explanations of LQ4 Engine, try Patsnap Eureka.