What is a Naturally Aspirated Engine?

A naturally aspirated engine is a classic powerhouse known for its simplicity and reliability. Unlike turbocharged or supercharged engines, it relies solely on atmospheric pressure to draw air into the combustion chamber, delivering a linear and responsive driving experience. In this article, we’ll explore how naturally aspirated engines work, their unique benefits, and why they continue to appeal to automotive enthusiasts around the world.

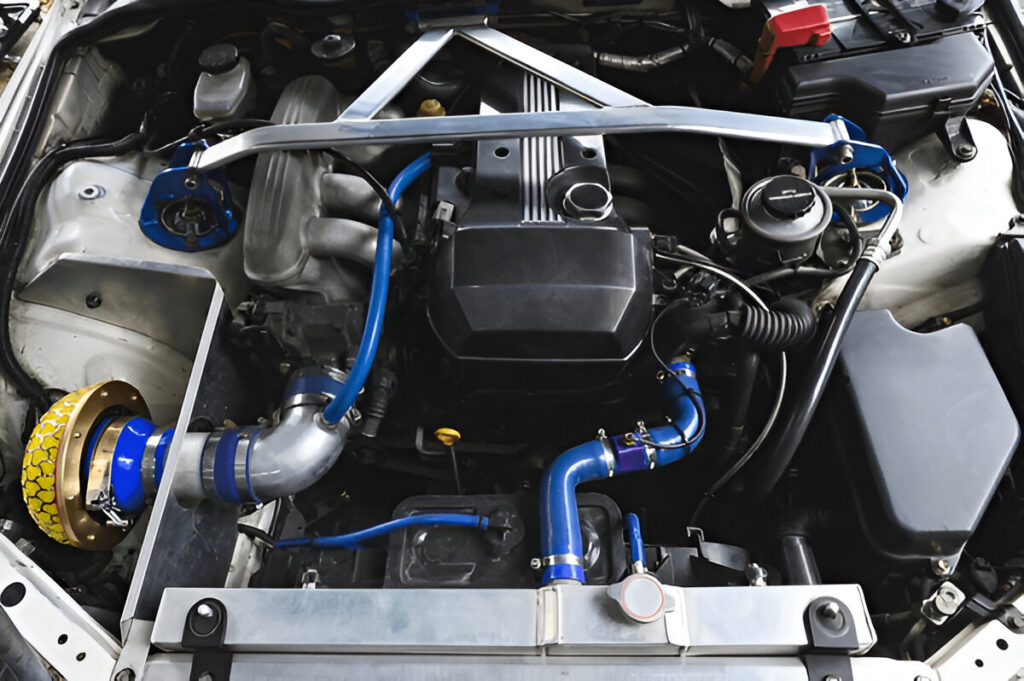

Key Components Involved

- Intake Manifold: This component directs the atmospheric air into the engine’s cylinders. The design of the intake manifold can significantly affect the engine’s performance by optimizing the air flow and reducing resistance.

- Pistons and Cylinders: The pistons move up and down within the cylinders, creating the necessary vacuum for air intake and compressing the air-fuel mixture. The efficiency of this process is measured by the volumetric efficiency, which is the ratio of the actual volume of air drawn into the cylinder to the theoretical volume.

- Spark Plugs: These are critical for igniting the air-fuel mixture at the right moment, ensuring efficient combustion and power generation.

- Exhaust System: The exhaust system, including the exhaust manifold and pipes, expels the burnt gases from the engine. In some high-efficiency designs, exhaust scavenging is used to create a vacuum that helps draw out the exhaust gases more effectively.

How Does a Naturally Aspirated Engine Work?

A naturally aspirated engine operates by drawing air into the combustion chamber through atmospheric pressure without the aid of forced induction devices like turbochargers or superchargers. The fundamental working principle involves several key steps:

- Intake Stroke: During the intake stroke, the downward movement of the piston creates a vacuum within the cylinder. This vacuum allows atmospheric air to be drawn into the cylinder through the open intake valve. The air-fuel mixture is then formed in the combustion chamber.

- Compression Stroke: The intake valve closes, and the piston moves upward, compressing the air-fuel mixture. This compression increases the mixture’s temperature and pressure, preparing it for ignition.

- Power Stroke: At the top of the compression stroke, the spark plug ignites the compressed air-fuel mixture. The resulting explosion forces the piston downward, generating mechanical power that is transferred to the crankshaft.

- Exhaust Stroke: The exhaust valve opens, and the upward movement of the piston expels the burnt gases from the combustion chamber through the exhaust manifold, completing the cycle.

Advantages of Naturally Aspirated Engines

Simplicity and Reliability

Naturally aspirated (NA) engines are known for their simpler design compared to forced induction engines like turbocharged or supercharged engines. This simplicity translates to fewer components that can fail, leading to increased reliability and lower maintenance costs. The absence of a turbocharger or supercharger means there are no additional parts such as intercoolers, wastegates, or blow-off valves, which can be potential points of failure.

Linear Power Delivery

NA engines provide a more linear and predictable power delivery. This is because the engine’s power output is directly related to the throttle position and engine speed, without the lag associated with turbochargers. This characteristic makes NA engines particularly suitable for applications where smooth and immediate throttle response is crucial, such as in sports cars and high-performance vehicles.

Lower Weight and Complexity

Without the need for additional components like turbochargers, intercoolers, and associated piping, NA engines are generally lighter and less complex. This reduction in weight can improve the overall vehicle dynamics, including handling and braking performance. Additionally, the simpler design can lead to easier and more cost-effective manufacturing processes.

Cost Efficiency

The production and maintenance costs of NA engines are typically lower than those of forced induction engines. The absence of forced induction components reduces the initial manufacturing costs and the long-term maintenance expenses. This cost efficiency makes NA engines an attractive option for budget-conscious consumers and manufacturers.

Fuel Efficiency at Low Loads

NA engines can be more fuel-efficient at low loads and during steady-state cruising. This is because they do not suffer from the pumping losses associated with forced induction systems, which can negatively impact fuel economy. For example, an NA engine can achieve better fuel efficiency in city driving conditions where the engine operates at lower speeds and loads.

Emissions and Environmental Impact

NA engines can have lower emissions compared to turbocharged engines, particularly in terms of particulate matter (PM) and nitrogen oxides (NOx). The absence of forced induction means that NA engines can operate with a more homogeneous air-fuel mixture, reducing the formation of PM and NOx. Engines powered by compressed natural gas (CNG) produce extremely low PM emissions. This is due to the uniformity of the air-gas mixture and the absence of large hydrocarbon chains and aromatics in the fuel, making CNG a cleaner and more environmentally friendly option.

Durability and Longevity

NA engines often have a longer lifespan compared to their forced induction counterparts. The lower operating temperatures and pressures in NA engines reduce the stress on engine components, leading to increased durability and longevity. This makes NA engines a preferred choice for applications where long-term reliability is essential, such as in commercial vehicles and heavy-duty machinery.

Performance Consistency

NA engines maintain consistent performance across a wide range of operating conditions. Unlike turbocharged engines, which can suffer from heat soak and reduced efficiency at high temperatures, NA engines are less affected by ambient temperature variations. This consistency ensures reliable performance in various environmental conditions.

Enhanced Driving Experience

The driving experience provided by NA engines is often preferred by enthusiasts due to the immediate throttle response and the linear power delivery. The absence of turbo lag and the direct connection between the throttle and engine response contribute to a more engaging and enjoyable driving experience.

Disadvantages of Naturally Aspirated Engines

Higher Emissions

These engines tend to produce higher levels of hazardous emissions, such as nitrous oxides (NOx) and carbon monoxide (CO), which can be detrimental to the environment.

Bulky Size

Despite being lighter, naturally aspirated engines can be bulkier in size compared to turbocharged engines, which can affect the design and packaging of the vehicle.

Inflexibility with Fuel Types

Conventional naturally aspirated engines are typically designed to run on a single type of fuel, making them less flexible compared to engines that can operate on multiple fuel types.

Maintenance Tips for Naturally Aspirated Engine

Timing Belt Replacement:

- Frequency: Every 60,000 to 100,000 miles.

- Procedure: Replace the timing belt and inspect related components like the water pump and tensioners.

Valve Adjustment

- Frequency: Every 30,000 to 60,000 miles, depending on the engine design.

- Procedure: Adjust the valve clearance to manufacturer specifications to ensure optimal engine performance.

Battery Maintenance

- Frequency: Check every 6 months.

- Procedure: Clean terminals, check electrolyte levels, and test the battery’s charge.

Applications of Naturally Aspirated Engine

Naturally aspirated engines (NAEs) power a wide range of applications thanks to their robustness and reliability. Automotive manufacturers use them extensively in passenger cars, motorcycles, and light trucks. In motorsports, NAEs dominate due to their precise tuning capabilities and performance optimization. Industries and agriculture also rely on these engines for machinery, valuing their simple design and long-lasting durability.

Application Cases

Automotive Industry: Naturally aspirated (NA) engines are a staple in light-duty vehicles due to their simple design, eliminating the need for complex turbocharging systems. This simplicity reduces manufacturing and maintenance costs. Studies show that while NA engines produce higher smoke emissions with biodiesel compared to diesel, they emit lower nitric oxide, offering optimization potential for specific fuel types.

Performance and Fuel Economy: NA engines perform efficiently across a wide range of operating conditions. Research shows they can compete with turbocharged engines in fuel economy on an equal brake mean effective pressure basis, particularly in consistent performance applications.

Alternative Fuels: NA engines are compatible with alternative fuels like methanol, demonstrating improved thermal efficiency and energy conservation potential, despite slight power declines when using renewable fuels.

Design Innovations: Innovative designs, such as integrated exhaust manifolds within cylinder heads, optimize exhaust flow, enhancing efficiency and performance in NA engines.

Latest Technical Innovations in Naturally Aspirated Engine

Advanced Valve Timing

Advanced valve timing systems, featuring camshaft phase adjusters and sensors, optimize intake and exhaust valve timing. This improves power, torque, fuel efficiency, and reduces emissions.

Gas Exchange Optimization

To meet emission standards like EU7, Gasoline Particulate Filters (GPFs) reduce particulate emissions but increase back pressure. Coupled simulation tools and rapid prototyping address these challenges, enhancing intake and exhaust dynamics for better performance.

Materials and Manufacturing

Lightweight materials improve engine efficiency by reducing vehicle weight, while rapid prototyping accelerates design and testing of innovative engine components.

Hybrid Integration

Hybrid technologies now complement naturally aspirated engines, allowing turbocharged systems to switch to naturally aspirated modes for improved efficiency at different speeds.

Small Displacement Engines

High-efficiency, low-displacement engines (as small as 1.3L) are being developed to balance fuel economy, emissions, and sufficient power output, meeting modern regulatory demands.

Enhanced Cooling Systems

Advanced cooling systems with improved radiators and pumps ensure optimal engine temperatures, boosting efficiency and reliability.

Emission Controls

Modern emission technologies like catalytic converters, EGR systems, and particulate filters minimize harmful emissions, making naturally aspirated engines more eco-friendly.

To get detailed scientific explanations of Naturally Aspirated Engine, try Patsnap Eureka.