Ceramic Coating Technology Background and Objectives

Ceramic coatings have emerged as a promising solution for various applications, offering improved properties such as wear resistance, thermal insulation, and corrosion protection. The development of environmentally friendly and non-toxic ceramic coatings has become a crucial area of research, driven by the growing demand for sustainable and eco-friendly materials.

The evolution of ceramic coatings can be traced back to the early 20th century when they were primarily used for decorative purposes. However, with advancements in materials science and coating technologies, ceramic coatings have found applications in diverse industries including aerospace, automotive, energy, and construction.

The primary objective of this research is to develop ceramic coatings that not only exhibit enhanced properties but also minimize environmental impact and potential health risks. This goal aligns with the global push towards sustainable practices and the increasing regulations surrounding the use of hazardous materials. Key targets for environmentally friendly and non-toxic ceramic coatings include improved wear resistance, thermal barrier properties, corrosion resistance, and chemical stability. Additionally, these coatings should be free from toxic substances such as heavy metals or harmful organic compounds and should be produced through environmentally responsible processes.

The development of such coatings has the potential to revolutionize various industries by providing durable, high-performance solutions while reducing the environmental footprint and promoting a safer working environment for personnel involved in their application and maintenance.

To get detailed scientific explanations of the ceramic coatings, try Patsnap Eureka TechResearch.

Market Demand for Eco-Friendly Ceramic Coatings

The market demand for eco-friendly ceramic coatings has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on the use of hazardous materials. These coatings are widely used in various industries including automotive, aerospace, construction, and consumer goods due to their excellent properties such as durability, corrosion resistance, and thermal stability.

One of the key drivers for the adoption of eco-friendly ceramic coatings is the increasing awareness of the negative impact of traditional coatings on the environment and human health. Traditional coatings often contain toxic substances like heavy metals, volatile organic compounds (VOCs), and hazardous air pollutants (HAPs), which can cause air and water pollution as well as pose risks to human health. In contrast, eco-friendly ceramic coatings are formulated without these harmful substances, making them a safer and more sustainable alternative.

Another factor driving the market demand is the implementation of stringent environmental regulations and standards by governments and industry bodies. Many countries have introduced strict limits on the use of hazardous materials in coatings, forcing manufacturers to explore eco-friendly alternatives. Additionally, industries such as automotive and aerospace have their own stringent requirements for the use of environmentally friendly materials, further fueling the demand for eco-friendly ceramic coatings.

Furthermore, consumer preferences have shifted towards more sustainable and environmentally conscious products, creating a significant market opportunity for eco-friendly ceramic coatings. Consumers are increasingly willing to pay a premium for products that are environmentally friendly and have a lower carbon footprint.

Moreover, industries increasingly adopt eco-friendly ceramic coatings, fueling significant market growth in the coming years. Additionally, the rising demand for sustainable and environmentally friendly products propels this expansion. However, the market also faces challenges such as higher costs associated with the development and production of these coatings, as well as the need for continuous innovation to improve their performance and properties.

Current State and Challenges of Ceramic Coatings

Ceramic coatings have gained significant attention in various industries due to their exceptional properties such as high hardness, wear resistance, and thermal stability. However, the current state of ceramic coatings faces several challenges that hinder their widespread adoption and limit their performance.

One of the primary challenges is the environmental impact associated with the production and application of ceramic coatings. Many traditional ceramic coating processes involve the use of hazardous materials such as hexavalent chromium compounds, which pose significant health and environmental risks. These processes often generate toxic waste streams, contributing to environmental pollution and raising concerns about sustainability.

Another challenge lies in the brittleness and poor adhesion of ceramic coatings to substrates. Ceramic coatings are inherently brittle, making them susceptible to cracking and delamination under mechanical stress or thermal cycling. Poor adhesion to the substrate can lead to premature failure of the coating, limiting its durability and service life.

Furthermore, the high processing temperatures required for many ceramic coating techniques can be energy-intensive and costly. This not only increases the overall production costs but also contributes to a larger carbon footprint, which is a growing concern in the context of environmental sustainability.

Geographical distribution of ceramic coating technologies also presents challenges. While advanced ceramic coating technologies are primarily concentrated in developed regions such as North America, Europe, and parts of Asia, access to these technologies may be limited in other parts of the world, hindering their widespread adoption and application.

Additionally, the complexity of ceramic coating processes and the need for specialized equipment and expertise can pose barriers to entry for smaller companies or emerging markets, limiting the dissemination of these technologies.

Addressing these challenges is crucial for the widespread adoption and sustainable development of ceramic coatings. Efforts are underway to develop environmentally friendly and non-toxic ceramic coating processes, improve adhesion and toughness properties, reduce processing temperatures, and facilitate technology transfer to enable global access to these advanced materials.

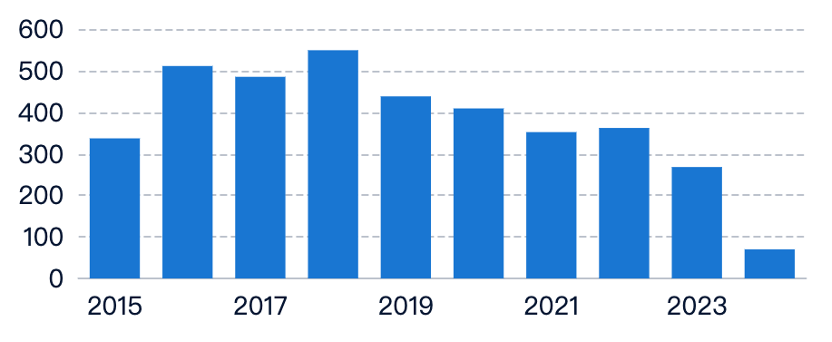

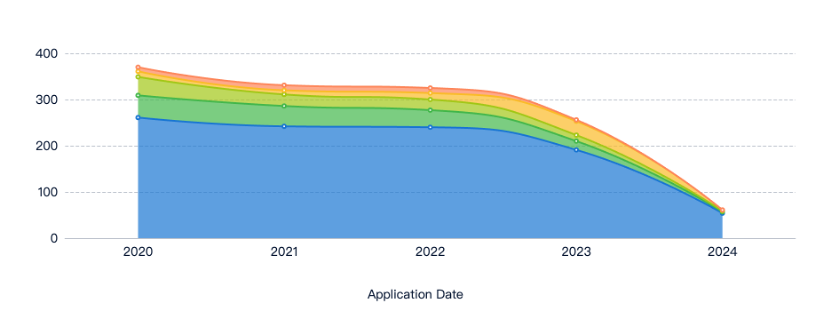

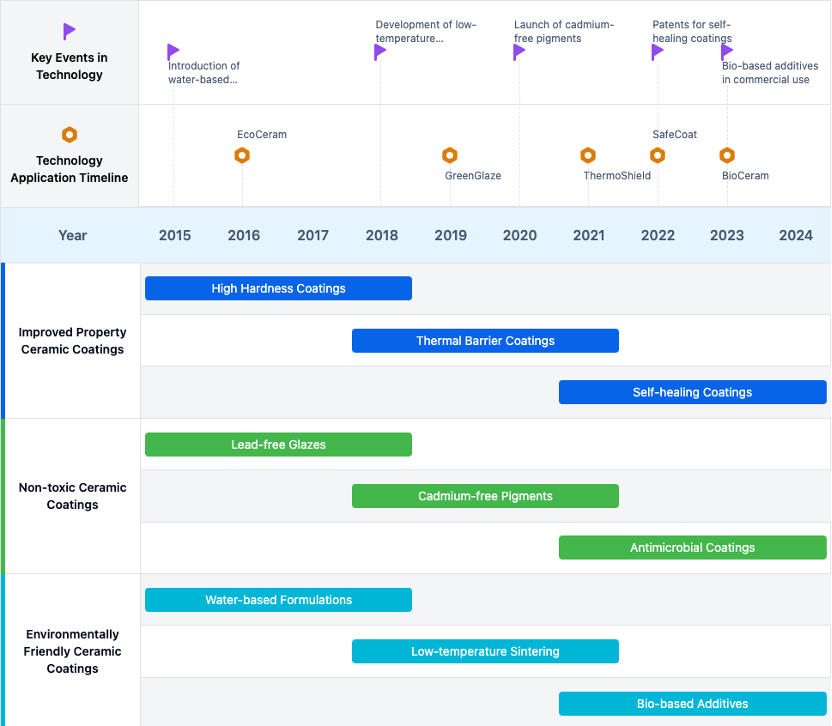

Evolution of Ceramic Coating Technologies

Existing Solutions for Non-Toxic Ceramic Coatings

Non-Toxic and Environmentally Friendly Coatings

Manufacturers formulate these coatings with non-toxic, eco-friendly materials, ensuring safety and reducing environmental impact. Additionally, they often use water-based or natural ingredients, avoiding harmful chemicals and solvents.

Water-Based Non-Toxic and Environmentally Friendly Coatings

Moreover, these coatings use water-based formulations without toxic or harmful solvents. Additionally, designers make them environmentally friendly and non-toxic, suitable for various indoor and outdoor surfaces.

Non-Toxic and Environmentally Friendly Coatings for Specific Applications

Manufacturers tailor these coatings for specific uses like automotive, wood, or flame-retardant applications while maintaining non-toxic and eco-friendly properties. Additionally, they design coatings to meet specific application needs, effectively minimizing environmental impact.

Non-Toxic and Environmentally Friendly Coatings with Additional Properties

These coatings not only possess non-toxic and environmentally friendly characteristics but also offer additional properties such as self-cleaning, water resistance, or fire resistance. They are designed to provide multiple benefits while maintaining their environmentally friendly and non-toxic nature.

Non-Toxic and Environmentally Friendly Ceramic Coatings

These coatings are specifically designed for use on ceramic surfaces, providing protection and enhancing the properties of the ceramic material while being non-toxic and environmentally friendly. They may offer features such as self-cleaning, wear resistance, or improved thermal barrier properties.

Key Players in Ceramic Coating Industry

The Research Foundation of The State University of New York

Actively researching non-toxic ceramic coatings with improved properties. Their approach involves the use of novel chemical formulations and environmentally friendly processes to enhance the performance and safety of ceramic coatings.

NDSU Research Foundation

Working on developing ceramic coatings that are both environmentally friendly and non-toxic. Their research focuses on improving the mechanical properties and longevity of these coatings through the use of sustainable materials and advanced manufacturing techniques.

NGK Insulators Ltd.

Developed a range of environmentally friendly ceramic coatings that are non-toxic and exhibit enhanced properties such as increased durability and resistance to high temperatures. Their technology focuses on using advanced materials and innovative processes to achieve these improvements.

Guangdong Carpoly Chemical Co. Ltd.

Developing non-toxic ceramic coatings with improved properties. Their technology emphasizes the use of eco-friendly raw materials and innovative chemical processes to achieve enhanced durability and performance.

Shenzhen Qianhai Graphene Industry Co. Ltd.

Introduced a new line of ceramic coatings that incorporate graphene to enhance their properties. These coatings are designed to be non-toxic and environmentally friendly, offering superior strength and thermal conductivity.

Core Innovations in Ceramic Coating Technologies

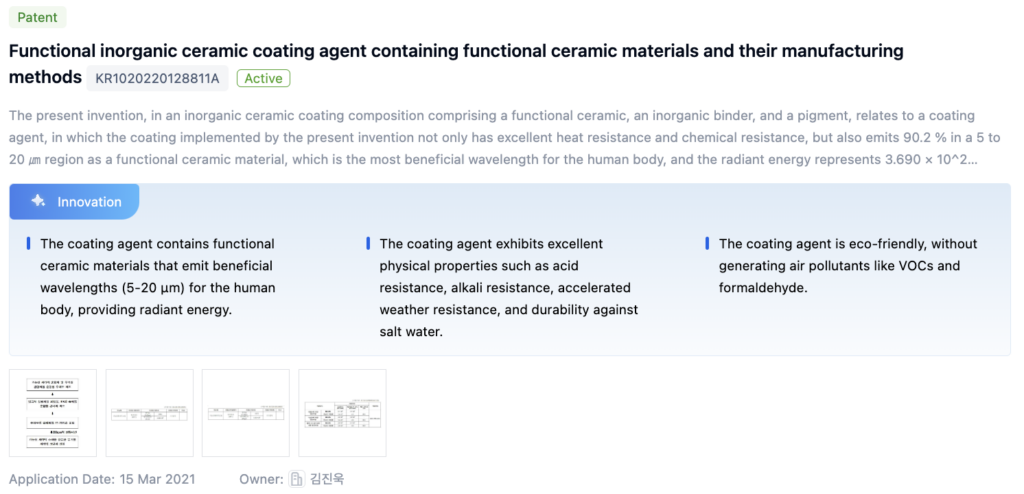

Patent 1: Functional Inorganic Ceramic Coating Agent

- Core Points:

- Emission of Beneficial Wavelengths: Contains functional ceramic materials that emit beneficial wavelengths (5-20 μm) for the human body, providing radiant energy.

- Excellent Physical Properties: Exhibits acid resistance, alkali resistance, accelerated weather resistance, and durability against salt water.

- Eco-Friendly: Does not generate air pollutants like VOCs and formaldehyde.

Patent 2: Long-Acting Anti-Aging Cathode Electrophoretic Paint

- Core Points:

- Combination of Resins: Utilizes epoxy resin and acrylic resin for long-term aging resistance and corrosion resistance.

- Enhanced Aging Resistance: The addition of black paste improves the aging resistance of the coating.

- Stable Formula: Uses an emulsifier and pH adjuster to ensure long-term stability and reliability of the emulsion.

Paper 1: Study Advance of Ceramic Coatings

- Core Points:

- Low-VOC Environment-Friendly Coating: Summarizes recent research advances in ceramic coatings, highlighting non-toxic properties and other eco-friendly benefits.

Paper 2: O-DE COAT G ECO

- Core Points:

- Advantages of Environmentally Friendly Coatings: Discusses low VOC emissions, non-toxicity, and other eco-friendly properties compared to traditional coatings.

Potential Breakthroughs in Eco-Friendly Ceramic Coatings

Non-Toxic and Environmentally Friendly Ceramic Coatings

Formulated using non-toxic and eco-friendly materials, these coatings are safe for both humans and the environment. They provide protection and functionality without compromising sustainability.

Water-Based and Biodegradable Ceramic Coatings

These ceramic coatings

are water-based and biodegradable, reducing their environmental impact. They are formulated using natural and renewable materials, making them an eco-friendly alternative to traditional coatings.

Self-Cleaning and Wear-Resistant Ceramic Coatings

These ceramic coatings possess self-cleaning and wear-resistant properties, enhancing their durability and reducing the need for frequent maintenance or replacement, thereby minimizing waste and environmental impact.

Ceramic Coatings for Specific Applications

These ceramic coatings are designed for specific applications, such as automotive, construction, or sports equipment, while maintaining their non-toxic and environmentally friendly properties.

Regulatory Landscape for Ceramic Coatings

Regulations on ceramic coatings are tightening to address environmental and health concerns. Many countries limit or ban harmful substances like heavy metals and VOCs in these coatings. Rules also push manufacturers to reduce emissions, waste, and energy use during production.

There’s a growing focus on eco-friendly and non-toxic coatings, with encouragement for using sustainable materials. Companies must keep up with these regulations to avoid penalties, and many are adopting compliance programs to demonstrate their commitment to safety and sustainability.

Environmental Impact of Ceramic Coating Technologies

While ceramic coatings are valued for their durability, their production can harm the environment. Traditional methods use hazardous materials and are energy-intensive, leading to pollution and higher energy consumption.

To reduce these impacts, more eco-friendly alternatives like sol-gel coatings and bio-based materials are being developed. Better waste management and recycling practices can also help. Considering the entire life cycle of these coatings is important for creating more sustainable solutions. Regulations play a key role in promoting greener practices and protecting the environment.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!