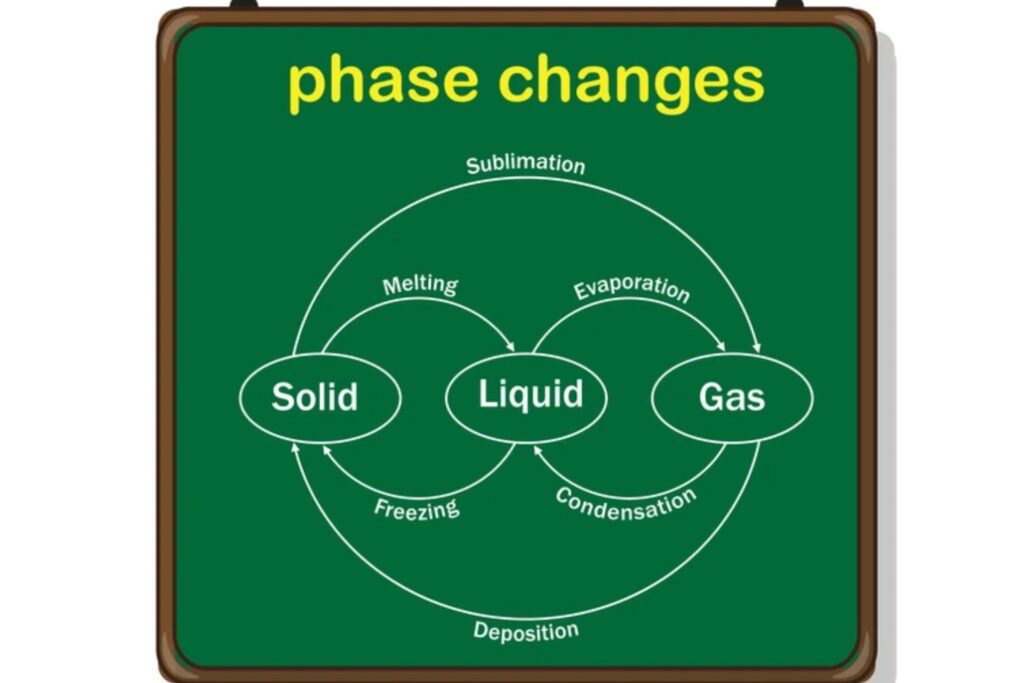

Phase Change Materials (PCMs) are smart thermal storage materials that absorb or release energy during phase transitions, typically between solid and liquid. These transitions enable passive temperature control across diverse industries. This blog introduces PCM classifications, thermal properties, market applications, technical innovations, and sustainability outlooks. We also explore how the PatSnap Eureka AI Agent empowers research teams to detect material trends and technology opportunities in real time.

What are Phase Change Materials?

PCMs utilize latent heat during phase changes to regulate temperature. They absorb heat during melting and release it during solidification, without significant changes in temperature. The three primary categories include:

- Organic PCMs – Paraffins, fatty acids

- Inorganic PCMs – Salt hydrates, metals

- Eutectic PCMs – Engineered blends with defined melting points

Composition & Properties / Performance

Chemical Structure & Identifiers

- Molecular Formula (varies): Common example – CₙH₂ₙ₊₂ (paraffin)

- CAS Numbers: Paraffin wax – 8002-74-2; Sodium sulfate decahydrate – 7727-73-3

- Melting Range: −10°C to 120°C

- Purity Grades: >95% for consistent cycling performance

Key Thermal & Physical Properties

| Property | Typical Value |

|---|---|

| Density | 0.8–1.5 g/cm³ |

| Melting Point | −10°C to 120°C |

| Latent Heat Capacity | 100–250 J/g |

| Thermal Conductivity | 0.2–0.6 W/m·K |

| Specific Heat | 1.5–3.0 J/g·K |

| Stability | >1000 thermal cycles |

Performance Features

- High energy density

- Stable cycling over hundreds of uses

- Available in microencapsulated, solid, or composite forms

- Non-corrosive and non-toxic options

Material Grades & Designations

Common PCM Grades

| Grade | Type | Melting Point | Use Case |

|---|---|---|---|

| RT21 | Paraffin | ~21°C | Smart textiles, HVAC |

| Salt Hydrate SH29 | Inorganic | ~29°C | Solar heating |

| Eutectic Blend | Hybrid | Customizable | Packaging |

| Bio-PCM | Organic | 20–30°C | Green construction |

Industry Standards

- ASTM E1225 – Thermal conductivity

- ISO 15927 – Moisture & thermal behavior

- EN 16359 – PCMs in building materials

Application Landscape

Major Industries

- Buildings – PCM drywall, panels, HVAC dampers

- Electronics – Thermal buffering, micro-device cooling

- Cold Chain Logistics – Vaccine containers, food boxes

- Automotive – Cabin comfort, battery thermal management

- Wearables & Apparel – Temperature-adaptive textiles

Real-World Example

BioPCM® materials are widely used in green-certified buildings in Europe to improve indoor thermal comfort while reducing HVAC energy demand by up to 30%.

Emerging Trends

- Textile-integrated PCMs in sportswear

- Fire-retardant PCMs for data centers

- Bio-sourced PCMs with low VOC emissions

Phase Change Materials vs Other Thermal Materials

| Feature | PCM | Insulation Foam | Gel Pack | Water |

|---|---|---|---|---|

| Energy Storage | High | Low | Medium | Low |

| Passive Control | Yes | No | Yes | No |

| Reusability | High | Low | Medium | Medium |

| Form Factor | Flexible | Rigid | Soft | Rigid |

Advantages of Phase Change Materials

- Store 5–14 times more heat than conventional insulation

- Enable thermal regulation without active power input

- Reduce peak energy loads in smart grids

- Lightweight and highly scalable

- Customizable melting points for specific industries

Innovations & Technology

Recent Developments

- Nano-PCM composites with higher thermal conductivity

- Biodegradable PCMs for eco-sensitive applications

- Shape-stabilized PCMs using polymer matrix supports

- Solar-triggered PCMs for building facades

Eureka Insights

- Hot Keywords: “graphene PCM,” “bio-based PCM,” “encapsulation”

- Leading Assignees: BASF, Honeywell, Rubitherm, Phase Change Energy

- White Spaces: Arctic-grade PCMs, flame-retardant composites, wearables

Sustainability & Environmental Impact

- Energy Savings: Up to 30% HVAC energy reduction

- Eco-friendly Formulations: Fatty-acid-based PCMs

- Reduced Emissions: Less reliance on powered cooling

- Compliance: REACH, RoHS, LEED credits achievable

- Lifecycle: Recyclable and stable over 1000+ cycles

PatSnap Eureka AI Agent Capabilities

- Identify and visualize PCM innovation clusters

- Track patent leaders in encapsulated and nano-PCM tech

- Explore regulatory compliance opportunities by geography

- Detect technology white space in medical-grade PCMs

- Benchmark R&D timelines and competitors’ IP filings

Conclusion

Phase Change Materials are transforming thermal energy storage and control. Their versatility in passive heating and cooling, combined with growing adoption across green buildings, electronics, and health logistics, highlights their strategic value. The integration of PCMs into composites and flexible formats further expands their potential. Tools like PatSnap Eureka offer material scientists and business leaders the insights needed to stay ahead of thermal innovation curves.

FAQs

PCMs range from −20°C to over 100°C depending on type and use.

No. Most commercial PCMs are non-toxic and safe for indoor use when properly encapsulated.

Yes, many PCMs can cycle thousands of times with minimal degradation.

Yes. Bio-based PCMs from fatty acids or plant oils are now widely available.

Yes. Encapsulation improves safety, performance, and longevity in practical use.

For more scientific explanations of PCMs , try PatSnap Eureka AI Agent.