Piezoelectric sensors are among the most versatile and high-performance sensing technologies available today. They function by converting mechanical stress into electrical signals, enabling precise measurement of force, pressure, acceleration, and vibration. These sensors are widely used across aerospace, healthcare, industrial automation, and consumer electronics. Their ability to deliver reliable and real-time data in dynamic environments makes them critical to smart devices and intelligent systems.

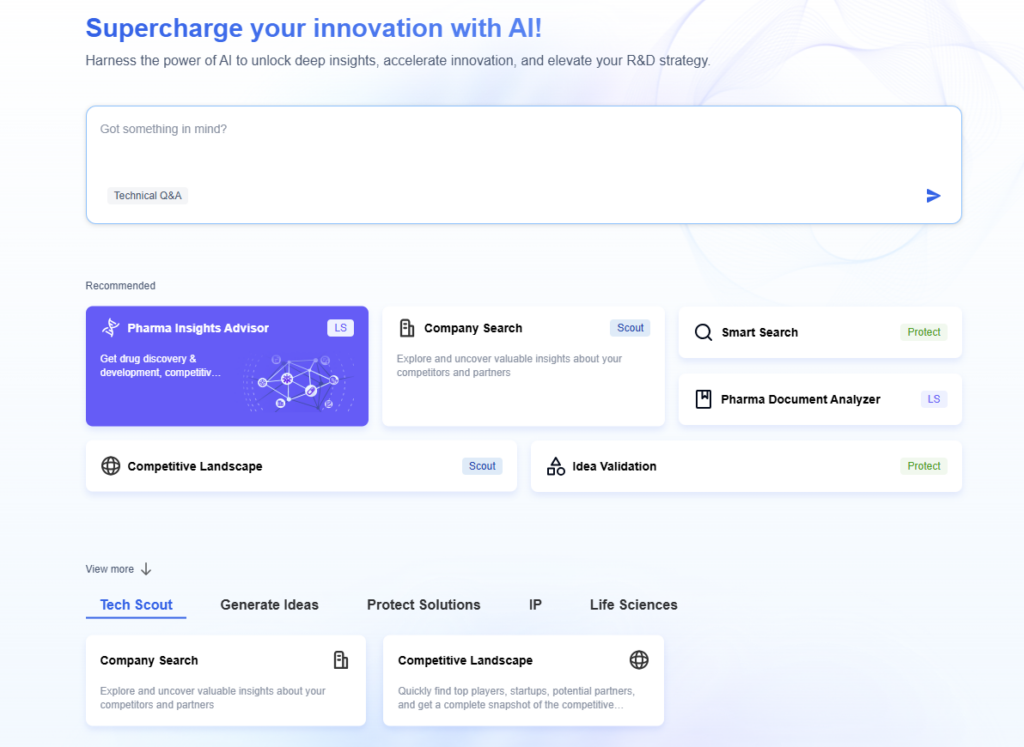

By integrating PatSnap Eureka AI Agent into the innovation process, companies and researchers can gain actionable intelligence on emerging materials, technology trends, patent filings, and competitive landscapes—turning data into strategic advantage in the fast-evolving piezoelectric sensor industry.

What is a Piezoelectric Sensor?

A piezoelectric sensor is a type of transducer that operates based on the piezoelectric effect. When certain crystalline materials—such as quartz, lithium niobate, or synthetic ceramics like PZT (lead zirconate titanate)—are subjected to mechanical stress or deformation, they produce a corresponding electric charge. This electrical output is proportional to the applied mechanical force.

Unlike resistive or capacitive sensors, piezoelectric sensors are particularly well-suited to measuring dynamic events. They are widely used in situations where high sensitivity, rapid response, and compact design are essential. These include detecting high-speed impacts, vibration monitoring, and real-time diagnostics in complex mechanical systems.

Key Characteristics of Piezoelectric Sensors

- High Sensitivity: Piezoelectric materials respond to even minute changes in mechanical stress, allowing the sensor to detect very subtle vibrations, pressure changes, or accelerations.

- Fast Dynamic Response: These sensors have a high natural frequency and fast rise time, making them ideal for high-speed measurements and transient signals.

- Wide Operating Temperature Range: Many piezoelectric sensors can operate in environments from -50°C to over 250°C, depending on material choice and design.

- Self-Generating Signal: No external excitation voltage is needed for signal generation. This simplifies integration and reduces power consumption.

- Durability and Ruggedness: With no moving parts, piezoelectric sensors are inherently durable. They perform well in harsh conditions, including those involving high pressure, high vibration, or corrosive environments.

- Compact and Lightweight: The sensor elements are small and light, allowing for easy integration into modern miniaturized electronics and embedded systems.

Types of Piezoelectric Sensors

Piezoelectric Accelerometers

Designed to measure vibration or acceleration in rotating machinery, engines, or structural components. They are widely used in aerospace, automotive, and civil engineering applications.

Piezoelectric Pressure Sensors

These sensors detect dynamic pressure changes in fluids or gases. They are essential in combustion engines, gas turbines, and hydraulic systems for real-time monitoring and control.

Piezoelectric Force Sensors

Used to measure applied force, torque, or load, especially in robotic arms, manufacturing machines, and surgical instruments. They offer precise and repeatable output under varying force conditions.

Piezoelectric Microphones and Speakers

Capable of converting sound into electrical signals (and vice versa), these components are found in communication devices, hearing aids, and embedded audio systems.

Piezoelectric Film Sensors

Flexible and thin, these are used in wearable electronics, smart textiles, and touch-sensitive applications. Their flexibility allows integration into curved or deformable surfaces.

Market Relevance and Competitive Positioning

The global market for piezoelectric sensors is experiencing sustained growth, driven by trends such as smart manufacturing, electrification of vehicles, and the proliferation of IoT devices. Asia-Pacific leads the market in production, while North America and Europe continue to dominate in R&D and high-end applications.

Key industry players include TE Connectivity, Honeywell International, Murata Manufacturing, Meggitt Sensing Systems, and PCB Piezotronics. These companies invest heavily in materials innovation, system integration, and MEMS-based piezoelectric devices.

Innovation and Technology

1. Material Innovations

Lead-Free Piezoelectrics

Researchers are actively developing lead-free alternatives to traditional PZT ceramics. These efforts respond to the growing need for environmentally friendly materials. Potassium sodium niobate (KNN)-based ceramics and molecular ferroelectrics are two promising candidates. These new materials often match or even exceed the performance of PZT. At the same time, they offer safer and more sustainable profiles.

One innovation involves a composite hydrogel with both piezoresistive and piezoelectric sensing abilities. It shows improved sensitivity and responds well across a broad frequency range. This makes it ideal for smart wearable strain sensors. In another study, scientists added MnFe₂O₄ nanoparticles to bacterial cellulose films. This boosted the films’ piezoelectric properties significantly.

Polymer-Based Piezoelectrics

Polyvinylidene fluoride (PVDF) and its copolymers are widely used. These materials are flexible, transparent, and electroactive. PVDF stands out for its high dielectric constant, excellent piezoelectric voltage output, and low acoustic impedance. It also offers strong mechanical strength, chemical stability, and moisture resistance. These properties make PVDF ideal for high-frequency and high-pressure environments.

However, PVDF comes with drawbacks. It is expensive, non-biodegradable, and lacks sustainability. To address these issues, researchers are studying renewable alternatives. One example is bacterial cellulose (BC) films. These bio-based materials show piezoelectric responses ranging from 5 to 15 pC/N.

Composite Materials

Engineers often combine ceramics and polymers to create piezoelectric composites. These materials balance flexibility with durability. For instance, composite hydrogels now integrate both piezoresistive and piezoelectric functions. They are already being used in wearable and stretchable strain sensors.

Another example is the piezoelectric composite (PEC) gas sensor. It combines advanced material design with integrated systems. As a result, PEC sensors are progressing rapidly in both performance and application range.

2. Design and Fabrication Innovations

Miniaturization

New microfabrication techniques have made it easier to build tiny piezoelectric sensors. Engineers can now embed these sensors into small devices. This is especially useful for wearables, smartphones, and IoT gadgets. The sensors remain compact while maintaining high sensitivity and accuracy.

MEMS Technology

Microelectromechanical systems (MEMS) play a key role in modern sensor design. MEMS allows manufacturers to create precise, highly sensitive piezoelectric devices. These sensors support a wide range of tasks, including force detection, vibration monitoring, and energy harvesting.

3D Printing and Additive Manufacturing

These technologies offer freedom in design. Engineers can build custom piezoelectric structures with complex shapes and functions. This opens new opportunities in medical devices, soft robotics, and energy systems. It also improves performance by matching sensor geometry to specific use cases.

Flexible and Stretchable Sensors

Researchers are pushing boundaries with soft, stretchable materials. These piezoelectric sensors can bend, flex, and stretch. They fit easily onto human skin or soft robotic surfaces. This capability makes them perfect for health monitoring, motion tracking, and responsive systems. Some versions even generate their own power, offering great potential in the IoT space.

3. Integration with Other Technologies

Energy Harvesting

Piezoelectric materials can turn motion into energy. When placed on machines, roads, or people, they capture mechanical vibrations. These vibrations become usable electricity. Thanks to material and structural improvements, today’s piezoelectric energy harvesters are more efficient and durable. They now power remote sensors, wireless nodes, and low-power devices.

Wireless Communication

Modern piezoelectric systems often include wireless features. This makes remote monitoring easier. For example, engineers use them in smart buildings, agriculture, and wearable tech. The sensor collects data, then transmits it wirelessly for analysis.

Artificial Intelligence and Machine Learning

Combining piezoelectric sensors with AI unlocks smarter systems. These sensors collect real-time physical data. AI algorithms then process the data, find patterns, and make decisions. This synergy boosts system adaptability and efficiency, especially in health and industrial monitoring.

Internet of Things (IoT)

Piezoelectric sensors are essential in connected environments. They continuously track pressure, motion, or force. Then, they send this data to a central platform or cloud. The result is a responsive, intelligent system that reacts to real-world changes instantly. IoT applications include smart homes, precision farming, and industrial automation.

Advantages of Piezoelectric Sensors

1. High Sensitivity and Resolution

Mechanical to Electrical Conversion

Piezoelectric sensors convert pressure, vibration, or force into electrical energy. This conversion is fast and highly sensitive. Materials like quartz, lithium niobate, and ceramics such as PZT and BaTiO₃ enable this effect. PZT stands out for its strong piezoelectric performance. Its voltage coefficient (g₃₃) typically ranges from 20–40 × 10⁻³ Vm/N. In contrast, PVDF polymer reaches 286.7 × 10⁻³ Vm/N. Despite its lower charge constant (d₃₃ ≈ 33 pC/N), PVDF has a low dielectric constant, which boosts its voltage output.

Wide Dynamic Range

These sensors handle a wide range of inputs. They detect tiny mechanical changes and withstand large forces. Their signal remains linear across that entire range. This feature ensures accuracy under varying loads.

Low Detection Limits

Even the smallest changes get detected. That’s why engineers use them in precision applications. You’ll find them in process monitoring, automotive systems, production technology, and non-destructive testing. They also appear in medical and consumer electronics.

2. Fast Response Time

Immediate Response

Piezoelectric sensors react instantly to force or pressure changes. This makes them ideal for measuring dynamic events. They respond quickly across different temperatures and environmental conditions.

High-Frequency Measurements

These sensors capture fast vibrations and oscillations accurately. Their ultrahigh frequency response gives them an edge over other types. Engineers use them for condition monitoring in bridges, machines, and engines. This helps prevent failure before it occurs.

3. Compact and Lightweight Design

Small Size

Piezoelectric sensors are small. You can easily integrate them into medical tools, electronics, or industrial devices. Despite their size, they offer speed, linearity, and strength.

Portability

Their low weight adds to their portability. These sensors support future tech like battery-free devices. They convert mechanical movements—like touch, flow, or motion—into readable signals. Applications include finger tracking, chemical sensing, and environmental monitoring.

4. Durable and Reliable

Long Operational Lifespan

These sensors last a long time. Their rugged design supports extended use, especially in energy-harvesting systems. They handle temperature extremes, chemicals, and vibrations without failure.

Minimal Maintenance

They have no moving parts. That means fewer breakdowns and less maintenance. A well-designed piezoelectric sensor often works for years without servicing. That reduces long-term system costs.

5. Versatility and Broad Applicability

Various Applications

These sensors are everywhere. In cars, they detect engine knock, pressure, or vibrations. In buildings, they support alarms and noise reduction systems. You’ll also find them in electric windows, mirrors, and seats. Medical tools, telecom devices, and diagnostic tools also rely on them. Beyond sensing, piezoelectric materials work in actuators, capacitors, and energy harvesters.

Different Materials

You can choose from quartz, ceramics, and polymers. Each offers unique benefits. Flexible polymers like PVDF combine with ceramic fillers to boost sensitivity. This hybrid design improves output and reliability. One promising lead-free material is 0.5BZT–0.5BCT. It matches the performance of PZT without using toxic lead.

6. Energy Harvesting Capability

Self-Powering

Piezoelectric sensors work without batteries. They collect ambient vibrations and convert them into usable energy. This makes them perfect for powering remote sensors and low-power electronics. Engineers already use them in wireless networks, industrial monitoring, and IoT systems.

Efficient and Durable

Recent designs improve energy output and lifetime. Harvesters last longer and withstand harsh environments. They provide clean, continuous power where battery use is limited or impractical.

7. Insensitivity to Electromagnetic Interference (EMI)

Resistance to EMI

These sensors resist electromagnetic noise. They remain accurate in environments with strong interference. That includes factories, power plants, and vehicles. This reliability ensures stable data under extreme conditions.

Limitations of Piezoelectric Sensors

- Inability to measure static or slowly changing signals due to signal decay.

- Low signal output often necessitates amplification circuits for processing.

- Performance can be affected by temperature variation and humidity.

- Certain commonly used materials, such as PZT, contain toxic lead components.

- Long-term performance may degrade under continuous high loads or exposure to corrosive environments.

Real-World Applications and Use Scenarios

Aerospace and Defense

Piezoelectric sensors are used for structural health monitoring, vibration analysis of engines and wings, and detecting impact forces on aircraft surfaces. In missile systems, they provide critical data for inertial navigation and shock monitoring.

Healthcare and Medical Devices

They play a key role in non-invasive medical diagnostics such as ultrasound imaging. Wearable health monitors also use piezoelectric films to track pulse rate, breathing patterns, and muscular movements.

Consumer Electronics

Devices like smartphones, game controllers, and smartwatches rely on these sensors for motion detection, gesture recognition, and haptic feedback. Touch-sensitive interfaces often incorporate thin piezoelectric layers.

Industrial Automation

Factories use them for machine condition monitoring, fault detection in rotating machinery, and quality control during manufacturing processes. Their high sensitivity to vibration and force enables predictive maintenance.

Automotive Systems

Modern vehicles use piezoelectric sensors in knock detection, tire pressure monitoring, and engine diagnostics. They help improve fuel efficiency, safety, and emissions control.

Energy Harvesting

Piezoelectric materials are capable of converting mechanical vibrations into usable electrical energy. This enables battery-less wireless sensor networks in remote or hard-to-reach locations.

PatSnap Eureka AI Agent Capabilities

The PatSnap Eureka AI Agent supports deep exploration of the piezoelectric sensor space by providing:

- Real-time patent mapping to track innovation in materials and sensor design.

- Cross-sector technology trend identification, linking piezoelectric developments with adjacent fields like MEMS and energy harvesting.

- Competitor benchmarking through portfolio analysis and IP strengths.

- Identification of white space opportunities and emerging tech leaders.

- Market activity heatmaps to prioritize R&D investments and partnerships.

With PatSnap Eureka, companies can translate complex IP data into concrete innovation strategies—ensuring they stay competitive in fast-paced sensor markets.

Conclusion

Piezoelectric sensors play a foundational role in enabling smarter, faster, and more responsive systems across industries. Their high sensitivity, versatility, and compatibility with miniaturized electronics make them essential in today’s interconnected world.

For organizations striving to lead in sensor innovation, PatSnap Eureka AI Agent serves as a strategic ally—offering advanced analytics, patent intelligence, and technology foresight to guide decision-making and accelerate breakthroughs.

FAQs

It converts mechanical stress (like pressure or vibration) into an electrical signal using piezoelectric materials.

They’re used in medical devices, automotive systems, industrial equipment, consumer electronics, and energy harvesting.

They generate an AC signal in response to dynamic mechanical changes.

Because they are highly sensitive, fast, compact, durable, and ideal for detecting dynamic forces with minimal power.

It refers to the ability of certain materials to generate an electric charge in response to applied mechanical stress.

No, they are designed for dynamic measurements. Static forces cause the signal to decay over time due to internal charge leakage.

For more scientific explanations of piezoelectric sensors, try PatSnap Eureka AI Agent.