Polyethylene terephthalate, commonly known as PET or PETE, is one of the most important and widely used thermoplastic polymers in the world. From beverage bottles and food containers to synthetic fibers and industrial films, PET plays an essential role in modern packaging, textiles, and consumer products.

Its popularity comes from its excellent mechanical properties, chemical resistance, lightweight nature, and high recyclability. In today’s sustainability-driven world, PET is not only valuable for its versatility but also for its role in the circular economy through advanced recycling processes.

Curious about Polyethylene Terephthalate (PET)? Eureka Technical Q&A explains PET’s key properties—strength, clarity, and recyclability—and helps you understand why industries widely use it in packaging, textiles, and sustainable product solutions.

This article explores everything you need to know about PET — its chemical structure, key properties, diverse applications, and how PET recycling is reshaping waste management and sustainable materials.

What Is Polyethylene Terephthalate (PET)?

Polyethylene terephthalate (PET) is a thermoplastic polymer resin belonging to the polyester family. Manufacturers produce it by polymerizing ethylene glycol with terephthalic acid or dimethyl terephthalate.

Chemists form PET by linking ethylene glycol and terephthalate monomers into a repeating long-chain polymer. Its molecular structure provides excellent strength, clarity, and barrier properties — making it ideal for both packaging and textile applications.

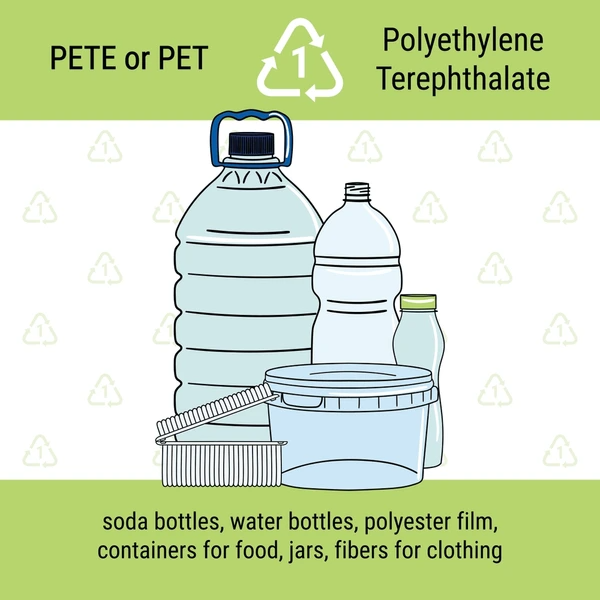

Recycling facilities identify PET by assigning it the number 1 within the universal recycling triangle symbol.

Key Properties of PET Material

Polyethylene terephthalate (PET) is a widely used thermoplastic polymer known for its excellent combination of properties, which make it suitable for a variety of applications. Here are some of the key properties of PET:

Nanocomposites of PET can provide superior performance in terms of strength and stability.

Mechanical Properties

- PET is known for its high strength and toughness, making it suitable for applications requiring durable materials.

- It has a high glass transition temperature (Tg) and melting point, which contribute to its thermal stability and resistance to deformation at high temperatures.

- PET exhibits good mechanical strength, including high tensile strength and impact resistance, which are essential for packaging and engineering applications.

Chemical Resistance

- PET has excellent chemical resistance, making it suitable for applications involving contact with various chemicals.

- It is resistant to moisture, alcohols, and solvents, which enhances its durability in different environmental conditions.

Optical Properties

- PET is known for its good optical clarity and transparency, which are important for packaging and food applications.

- It has high light transmission, making it suitable for optoelectronic applications.

Thermal Properties

- PET has good thermal stability, allowing it to withstand a wide range of temperatures without significant degradation.

- It has a high heat distortion temperature (HDT), which indicates its resistance to deformation under heat.

Recyclability

- PET is highly recyclable, which is one of its major advantages in the packaging industry.

- It can be recycled multiple times without losing its properties, which contributes to its sustainability.

Barrier Properties

- Manufacturers use PET in packaging because it provides good gas barrier properties and minimizes moisture and gas transmission.

- It provides an effective barrier against oxygen, nitrogen, and carbon dioxide.

Processing Properties

- PET can be easily processed using various techniques such as injection molding, extrusion, and blow molding.

- It has good flow properties, which make it suitable for mass production.

Nanocomposite Properties

When combined with nanomaterials like graphene, PET can exhibit enhanced mechanical, thermal, and gas barrier properties.

Applications and Uses of PET

PET is incredibly versatile and used across multiple industries for packaging, textiles, and engineering purposes.

1. Packaging Industry

- Beverage bottles (water, soda, juice)

- Food containers and trays

- Salad and fruit packaging

- Cooking oil bottles

- Cosmetic and pharmaceutical containers

2. Textile Industry

- Polyester fibers for clothing

- Carpets and upholstery fabrics

- Industrial yarns and ropes

- Home furnishing textiles

3. Engineering Plastics

- PET films for flexible packaging

- Electrical insulation

- 3D printing filaments

- Automotive components

4. Industrial Applications

- Strapping materials for shipping

- Blister packaging

- Photo and X-ray films

PET’s broad utility arises from its combination of strength, transparency, and chemical resistance.

Advantages of Using PET Material

| Advantages | Benefits in Application |

|---|---|

| High strength-to-weight ratio | Light but durable packaging |

| Excellent clarity | Ideal for transparent containers |

| Good barrier properties | Prolongs product shelf life |

| Chemical resistance | Suitable for food and beverages |

| Lightweight | Reduces shipping costs |

| Fully recyclable | Supports circular economy goals |

Environmental Impact and Recycling of PET

PET’s recyclability is one of its most significant environmental advantages, reducing plastic waste and conserving resources. Recycled PET is often referred to as rPET.

PET Recycling Process

- Collection of used PET products

- Sorting and cleaning

- Grinding into flakes

- Washing and decontaminating

- Melting and reprocessing into new products

rPET is used to manufacture:

- New bottles and containers

- Polyester fibers for textiles

- Food packaging

- Carpets and construction materials

Benefits of PET Recycling

- Reduces landfill waste

- Lowers greenhouse gas emissions

- Conserves energy compared to producing virgin PET

- Reduces demand for raw petroleum resources

- Enables closed-loop recycling systems

Challenges in PET Recycling

Despite its recyclability, PET recycling faces several challenges:

- Contamination from food residues or other plastics

- Sorting inefficiencies in waste management

- Downcycling into lower-grade products in some cases

- Market fluctuations in rPET demand and prices

However, advancements in chemical recycling and better waste sorting technologies are helping to overcome these limitations.

PET vs. Other Plastics

- Polyethylene (PE): PE is more flexible and has better barrier properties against moisture and oxygen compared to PET. However, it is less durable and has lower chemical resistance.

- Polypropylene (PP): PP is similar to PE in terms of flexibility and barrier properties. However, it has lower chemical resistance compared to PET.

- Polyvinyl chloride (PVC): PVC has better barrier properties and chemical resistance compared to PET. However, it is less durable and has higher environmental impact if not properly recycled.

- Polybutylene terephthalate (PBT): PBT has similar properties to PET but with better impact resistance and higher heat distortion temperature. However, it is more expensive and has limited recycling options.

| Material | Key Feature | Limitation |

|---|---|---|

| PET | Lightweight, strong, recyclable | Sensitive to high heat over 250°C |

| HDPE | Excellent chemical resistance | Less transparent |

| PVC | Flexible, versatile | Contains chlorine, environmental concerns |

| PP | Heat resistant | Less transparent |

| PS | Lightweight, rigid | Brittle, poor recycling rate |

Future of PET in Sustainable Packaging

The future of PET is closely tied to sustainability trends and technological advancements in recycling. Leading packaging companies are focusing on:

- Increasing rPET content in new bottles

- Developing fully recyclable PET packaging

- Improving chemical recycling techniques to break PET down to its monomers for reuse

- Designing bottles for better recyclability (e.g., removing colored PET or labels that interfere with recycling)

PET’s role in the circular economy is expected to grow as industries prioritize reducing plastic waste and improving resource efficiency.

Conclusion

Polyethylene terephthalate (PET) has become a crucial material in the modern world due to its excellent strength, clarity, lightweight nature, and recyclability. Used extensively in packaging, textiles, and industrial products, PET offers an effective balance between performance and sustainability.

As recycling technologies advance and consumer demand for sustainable packaging increases, PET — particularly recycled PET (rPET) — will continue to play a vital role in reducing plastic waste and supporting the future of circular materials.

FAQs

Yes, PET is approved by health and safety agencies worldwide for food and beverage packaging.

rPET stands for recycled polyethylene terephthalate — PET material that has been recovered and processed for reuse.

Chemical recycling technologies break down and rebuild PET almost indefinitely, although mechanical recycling still has its limits.

Look for the recycling symbol with the number 1 on the product.

Manufacturers still derive PET from petroleum, but its high recyclability makes it more sustainable than many other plastics, especially in closed-loop recycling systems.

To get detailed scientific explanations of Polyethylene Terephthalate (PET), try Patsnap Eureka.