Polyol is a class of organic compounds characterized by multiple hydroxyl (-OH) groups. They serve as key raw materials in manufacturing polymers such as polyurethanes and polyester resins. Polyols vary widely in molecular weight and structure, influencing their physical properties and application scope.

This blog explores polyol materials’ chemical composition, performance characteristics, and material grades. It also covers their extensive applications in industries like coatings, adhesives, cosmetics, and construction. Moreover, we highlight innovation trends shaping polyol development and explain how the PatSnap Eureka AI Agent supports research and competitive intelligence. By leveraging Eureka, companies can accelerate innovation and maintain an edge in this evolving market.

What is Polyol?

Polyols, also known as polyhydric alcohols, contain multiple hydroxyl functional groups. Common types include:

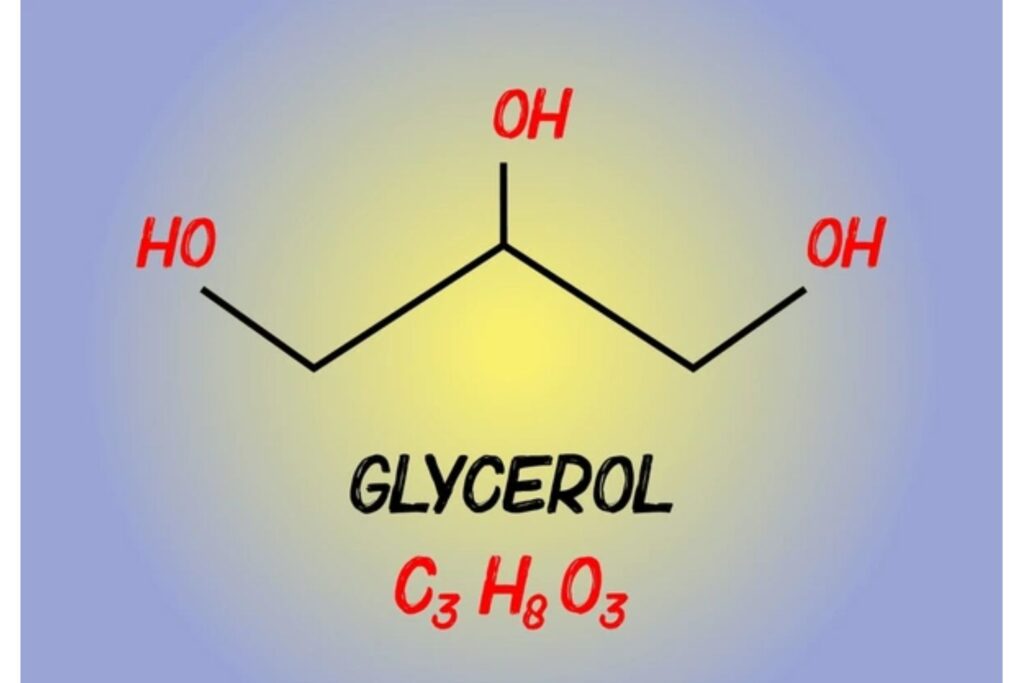

- Glycerol (C3H8O3)

- Sorbitol (C6H14O6)

- Pentaerythritol (C5H12O4)

- Polyether and polyester polyols used in polymer synthesis

These compounds differ in molecular size, functionality, and chemical backbone, which determine their suitability for various industrial processes.

Composition & Properties/Performance

| Property | Typical Values |

|---|---|

| Molecular Formula | Varies (e.g., C3H8O3 for glycerol) |

| CAS Number | Depends on specific polyol (e.g., 56-81-5 for glycerol) |

| Physical State | Generally liquid or solid (powder or crystals) |

| Density | 1.0 – 1.3 g/cm³ (varies by type) |

| Melting Point | Ranges widely (-20°C to 180°C) |

| Viscosity | Low to high, depending on molecular weight |

| pH | Typically neutral to slightly acidic/basic |

Functional Properties:

- Excellent moisture retention and hygroscopicity

- Reactive hydroxyl groups enable cross-linking and polymerization

- Good thermal and chemical stability depending on structure

Material Grades & Designations

Polyols are categorized based on source and polymer type:

| Standard System | Grade/Designation | Use Case |

|---|---|---|

| ASTM | ASTM D 2000 (polyurethanes) | Polyurethane foams, elastomers |

| GB (Chinese) | GB/T 2918 (polyols) | Coatings, adhesives |

| USP | Pharmaceutical Grade | Cosmetic and pharmaceutical use |

Equivalent grade conversions depend on region and industry application.

Application Landscape

Polyols find applications in many industries:

- Polyurethane Foams: Flexible and rigid foams for furniture, insulation, automotive parts

- Coatings & Adhesives: Durable, chemical-resistant finishes and bonding agents

- Cosmetics: Moisturizers, humectants, and emollients in skincare products

- Construction: Sealants and composite materials

- Textiles & Elastomers: Soft, flexible materials with high tensile strength

Example: A leading polyurethane manufacturer uses polyester polyols to improve foam resilience and environmental profile.

Trends:

- Increasing use of bio-based polyols from renewable feedstocks

- Developing low-VOC and non-toxic formulations due to regulatory pressures

- Enhanced polyols with improved thermal and mechanical properties for advanced composites

Polyol vs Other Similar Materials

| Feature | Polyols | Glycols | Polyesters |

|---|---|---|---|

| Functionality | Multiple -OH groups | Typically 2 -OH groups | Polymer chains |

| Application | Polymer precursors, humectants | Solvents, antifreeze | Fibers, resins |

| Biodegradability | Varies, many bio-based | Usually low | Varies by polymer type |

| Reactivity | High, for crosslinking | Moderate | Low to moderate |

Advantages of Polyols

- Wide chemical versatility enabling diverse applications

- Compatibility with various polymerization chemistries

- Renewable feedstock availability for bio-based variants

- Enhanced physical and chemical stability in formulations

- Support for sustainable product development goals

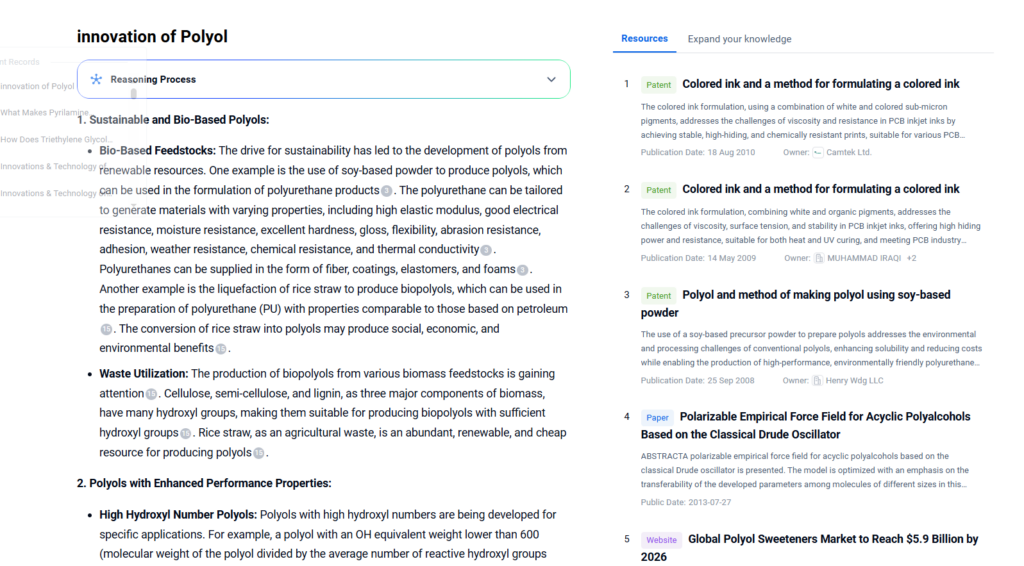

Innovations & Technology

- Bio-Based Polyols: Use of vegetable oils, lignin, and sugar derivatives to replace petrochemical polyols

- High-Functionality Polyols: Tailored for improved crosslink density and mechanical properties

- Nanocomposite Polyols: Incorporation of nanoparticles to enhance durability and flame retardancy

- Green Synthesis Processes: Reducing energy use and hazardous chemicals in production

- AI-Driven R&D: PatSnap Eureka AI Agent identifies emerging patents and innovation trends, guiding faster product development

Sustainability & Environmental Impact

- Growing shift towards renewable polyols reduces carbon footprint

- Biodegradability and non-toxicity are key development targets

- Compliance with REACH, RoHS, and other eco-regulations

- Efforts to minimize VOC emissions in formulations using polyols

PatSnap Eureka AI Agent Capabilities

- Real-time patent landscape mapping for polyol technologies

- Competitive intelligence on emerging bio-based and specialty polyols

- Innovation trend forecasting and IP risk management

- Insights into regulatory changes affecting materials development

Conclusion

Polyols are versatile, functional materials integral to many industries. Their chemical diversity and reactive hydroxyl groups make them essential in polymers, coatings, cosmetics, and more. Innovation focuses on bio-based sources, enhanced performance, and environmental compliance.

Using PatSnap Eureka AI Agent, companies can unlock deep insights to accelerate polyol research and stay competitive. With sustainability and advanced technology at the forefront, polyols will continue to drive material innovation in the future.

FAQs

Polyols are organic compounds with multiple hydroxyl groups used mainly as polymer precursors.

Polyurethane foams, cosmetics, coatings, adhesives, and construction.

They derive from renewable resources and offer environmental benefits.

Many bio-based polyols are biodegradable, but it depends on the chemical structure.

For more scientific explanations of Polyols , try PatSnap Eureka AI Agent.