Prusa MK4 isn’t just an upgrade—it’s a reinvention of 3D printing accessibility and performance. As the successor to the legendary MK3, this machine redefines what a consumer – grade 3D printer can do. With a 90% overhaul of components, it packs cutting – edge tech like input shaping and pressure advance for silent, high – speed prints. The Nextruder system automates precision, from first – layer leveling to nozzle swaps, while smart connectivity and material versatility (plus MMU3 compatibility) make it a Swiss Army knife for creators. Whether you’re a hobbyist chasing speed or a pro demanding reliability, the MK4 bridges innovation and ease—proving Prusa’s open – source legacy still leads the 3D printing revolution.

Looking into Prusa’s rapid iteration and innovation cycle, PatSnap Eureka AI Agent provides deep technical insights into patented printhead designs, material compatibility, and hardware-software synergies—empowering professionals to decode the competitive edge behind the MK4.

What is the Prusa MK4?

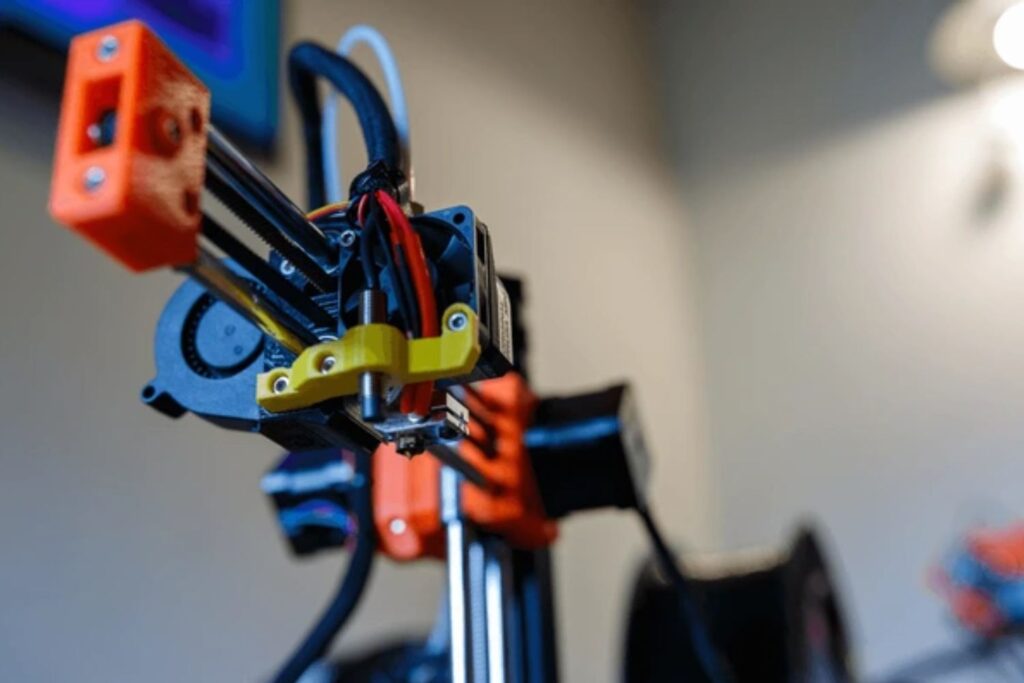

The Prusa MK4 is the successor to the acclaimed MK3S+, designed and manufactured by Prusa Research, a leading name in consumer and professional 3D printing. It’s built on a new 32-bit architecture with advanced motion control systems, a redesigned extruder (Nextruder), and a host of usability features that elevate it beyond traditional desktop printers.

With roots in open-source engineering and a vast user community, the MK4 is both a plug-and-play solution and a platform for deep customization.

Key Specifications of the Prusa MK4

| Feature | Specification |

|---|---|

| Build Volume | 250 × 210 × 220 mm |

| Printing Technology | Fused Deposition Modeling (FDM) |

| Nozzle Type | Custom Nextruder with Load Cell |

| Layer Resolution | 0.05–0.3 mm |

| Maximum Print Speed | Up to 250 mm/s |

| Firmware | Prusa Input Shaper (32-bit STM32 board) |

| Material Compatibility | PLA, PETG, ABS, ASA, PC Blend, etc. |

| Connectivity | USB, LAN, Wi-Fi |

| Automatic Bed Leveling | Yes (Load Cell-based) |

| Power Recovery & Filament Sensor | Yes |

Real-World Applications & Use Scenarios

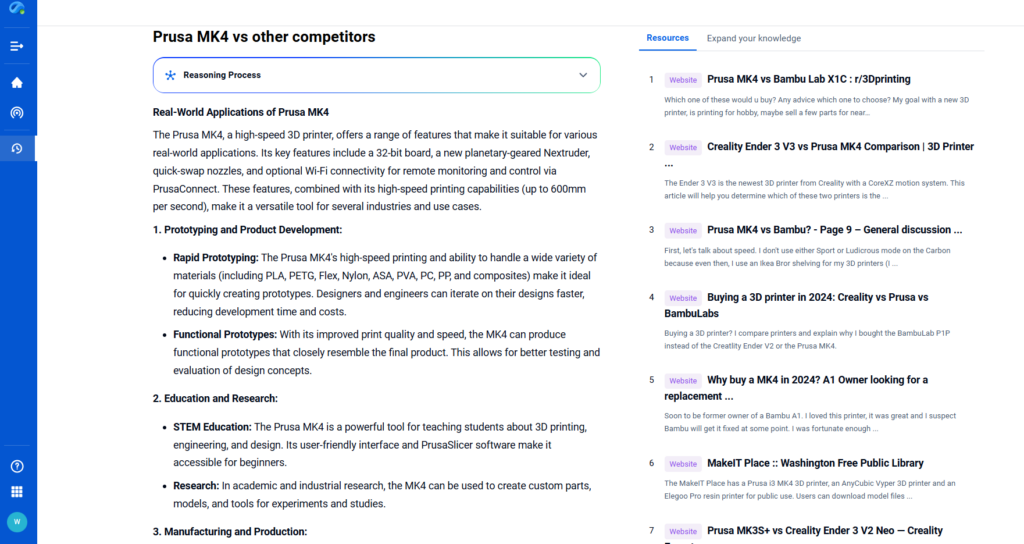

The Prusa MK4, a high-speed 3D printer, offers a range of features that make it suitable for various real-world applications. Its key features include a 32-bit board, a new planetary-geared Nextruder, quick-swap nozzles, and optional Wi-Fi connectivity for remote monitoring and control via PrusaConnect. These features, combined with its high-speed printing capabilities (up to 600mm per second), make it a versatile tool for several industries and use cases.

1. Prototyping and Product Development

- Rapid Prototyping: The Prusa MK4’s high-speed printing and ability to handle a wide variety of materials (including PLA, PETG, Flex, Nylon, ASA, PVA, PC, PP, and composites) make it ideal for quickly creating prototypes. Designers and engineers can iterate on their designs faster, reducing development time and costs.

- Functional Prototypes: With its improved print quality and speed, the MK4 can produce functional prototypes that closely resemble the final product. This allows for better testing and evaluation of design concepts.

2. Education and Research

- STEM Education: The Prusa MK4 is a powerful tool for teaching students about 3D printing, engineering, and design. Its user-friendly interface and PrusaSlicer software make it accessible for beginners.

- Research: In academic and industrial research, the MK4 can be used to create custom parts, models, and tools for experiments and studies.

3. Manufacturing and Production

- Small-Batch Production: The MK4’s speed and reliability make it suitable for small-scale manufacturing of end-use parts. It can produce high-quality parts with consistent results.

- Custom Manufacturing: The ability to print with a variety of materials and colors (using the MMU3 for multicolor printing) allows for the creation of customized products on demand.

4. Hobbyist and Maker Projects

- Home Projects: Hobbyists can use the Prusa MK4 to create a wide range of items, from household gadgets and toys to decorative objects and jewelry.

- DIY Repairs: The MK4 can be used to print replacement parts for broken items, saving time and money.

5. Architecture and Construction

- Architectural Models: The MK4 can produce detailed and accurate architectural models, helping architects and designers visualize their projects.

- Construction Components: In the construction industry, the MK4 can be used to create custom components, molds, and tools.

6. Healthcare and Medical Applications

- Medical Models: The MK4 can produce highly detailed anatomical models for medical training and education.

- Prosthetics and Orthotics: With its ability to print with flexible materials, the MK4 can be used to create custom prosthetics and orthotics.

- Dental Applications: The MK4 can print dental models, aligners, and other dental appliances.

7. Automotive and Aerospace

- Prototyping Parts: In the automotive and aerospace industries, the MK4 can be used to prototype and test new parts and components.

- Tooling and Fixtures: The MK4 can create custom tools, jigs, and fixtures for manufacturing and assembly processes.

8. Art and Design

- Sculptures and Art Installations: Artists can use the MK4 to create intricate sculptures and art installations.

- Jewelry and Fashion: The MK4 can print detailed jewelry pieces and fashion accessories.

Innovation & Technology of Prusa MK4

Mechanical Innovations

- Frame Design: The Prusa MK4 features a new aluminum composite injection-molded frame, replacing the sheet metal frame of the MK3. This change provides greater rigidity, which is crucial for maintaining accuracy at high printing speeds. The frame is thicker, adding stability needed for the increased acceleration of the new machine.

- Extruder System: The Prusa MK4 introduces the “Nextruder,” a high-speed extruder based on the design first seen on the Prusa XL. This extruder uses a dual-gear system to control filament flow, offering greater control, especially with flexible filaments like TPU. The Nextruder also features quick-swap nozzles, allowing for easy changes between different nozzle sizes without tools. The planetary-geared Nextruder has a larger surface area touching the filament, enabling better control over filament movement.

- Bed Levelling and Calibration: The MK4 includes a Load Cell sensor for fully automatic first-layer calibration. This sensor allows for precise adjustment of the first layer height, even when using different nozzles, eliminating the need for manual Z-axis adjustment. The auto-bed leveling system is one of the key features that set the MK4 apart from its predecessor.

Print Quality Enhancements

- Printing Speed: The MK4 is designed for high-speed printing, with a maximum print speed of 600mm per second. The new extruder and frame design contribute to this increased speed while maintaining high print quality.

- Filament Compatibility: The MK4 supports a wide variety of 1.75mm filament types, including PLA, PETG, Flex, Nylon, ASA, PVA, PC, PP, and composites.

- Print Bed: The MK4 features a new print bed with an improved surface texture, providing better adhesion and eliminating the need for adhesives or other surface treatments.

User Experience Improvements

- Connectivity: The MK4 offers upgraded connection options, including Ethernet and Wi-Fi, allowing for remote printing and easier file transfers. An optional ESP Wi-Fi board is available for remote monitoring and control via PrusaConnect.

- User Interface: The MK4 has a 3.5-inch color LCD screen, making it easy to navigate the user interface and control the printer locally. A new graphic LCD interface has also been added, replacing the old segmented LCD of previous models. This color LCD screen can support G-code thumbnails, longer texts, graphics, and QR codes. An RGB status bar has been added below the LCD screen, with a programmable set of RGB LEDs using various colors to indicate the current state of the printer. A USB-A port has also been added next to the display, allowing the user to use a USB flash drive to store G-Codes.

- Filament Sensor: The MK4 has a new filament sensor that detects when the filament runs out and automatically pauses the print, allowing users to easily swap out filaments without starting the print job all over again.

- Safety Features: The MK4 has new safety shutdown features that can be triggered by the printer if it detects an issue.

Open-Source Aspects

- Firmware: The MK4 includes Klipper-inspired custom firmware.

- Upgrades and Accessories: Prusa has announced the new Multi-Material Upgrade 3 (MMU3), which is compatible with both MK3S+ and MK4 models. This optional add-on allows the single extruder printer to print with up to 5 colors at a time, with the MMU3 offering improved reliability and easier controls than previous versions. Moreover, the MK4 is also compatible with the MMU3 for multicolor printing using up to five filament colors. Various accessories, including an enclosure and the MMU3, are available, but sold separately. And upgrade packages for existing MK3S+ models, including MK3.5, MK3.9, and MK4 upgrade options, are also available. The MK4->MK4S Upgrade Kit contains everything needed to fully upgrade a stock MK4 3D printer to the new MK4S.

Other Notable Features

- Build Volume: The MK4 has a build volume of 9.84 x 8.3 x 8.6 inches.

- Dimensions: The MK4 has dimensions of 500 × 550 × 400 mm. The height of the MK4 is 10mm bigger than the MK3.

- Weight: The MK4 weighs 16 kg.

- Power Requirements: The MK4 requires a power supply of 24V DC.

- Noise Level: The MK4 has a noise level of 50 dB.

- Warranty: The MK4 comes with a 1-year warranty.

- Price: The MK4 is available as a kit for $799 and as a fully assembled printer for $1099. The MK4S is available for $1,099. The MK4 is considered a pricey printer.

Prusa MK4 vs. Other 3D Printers

| Feature | Prusa MK4 | Prusa MK4S |

|---|---|---|

| Print Speed | Fast, up to 600 mm/s | Even faster and more consistent at high speeds |

| Accuracy | High precision | Improved accuracy via planetary-geared Nextruder |

| Extruder | Standard high-speed Nextruder | Upgraded with more grip/control over filament |

| Bed Leveling | Fully automatic via Load Cell | Same Load Cell system with consistent performance |

| Connectivity | Ethernet + Wi-Fi (optional ESP board available) | Same, supports remote control via PrusaConnect |

| Filament Sensor | Yes, with auto-pause on filament run-out | Identical functionality |

| Price | Starts at $799 (kit) / $1,099 (assembled) | Slightly higher; $1,099 baseline for MK4S |

Summary:

MK4S builds on the MK4 with enhanced extruder control and better performance at higher speeds, making it ideal for advanced users or production workflows. For most users, the MK4 already delivers excellent speed, accuracy, and reliability at a more competitive price point.

And want to compare the mechanical upgrades in detail? Use PatSnap Eureka AI Agent to analyze patented Nextruder innovations and motion-control enhancements between MK4 and MK4S.

Conclusion

The Prusa MK4 marks a thoughtful evolution in the FDM printing world—blending reliability, speed, and innovation. Its appeal spans casual users to professionals, offering open-source flexibility backed by refined hardware. With embedded sensor technologies, smarter firmware, and ecosystem enhancements, MK4 defines the next generation of desktop 3D printing.

For companies exploring additive manufacturing technologies or monitoring competitors like Prusa, PatSnap Eureka delivers a unique advantage—translating technical documents, patents, and product insights into actionable R&D intelligence.

FAQs

Absolutely. The auto-calibration, intuitive touchscreen UI, and robust print profiles make it ideal for new users.

MK4 has faster print speeds, better first-layer automation, a 32-bit board, and advanced motion control. It’s an across-the-board upgrade.

Yes, the MK4 supports LAN and Wi-Fi control via PrusaConnect.

It depends. PrusaSlicer excels for Prusa printers (optimized, seamless integration). Cura is more flexible, supports wider hardware, and has a huge plugin ecosystem. Pick based on your printer (Prusa? → PrusaSlicer; diverse setups? → Cura).

Yes. The MK4S uses a “bed slinger” design—print bed moves (Y – axis), while the print head stays stationary (X – axis). Common in many consumer 3D printers for simplicity/cost – efficiency.

To get more detailed scientific explanations of the Prusa MK4, try PatSnap Eureka AI Agent.