Technical Background and Objectives of Rack and Pinion Systems

The rack and pinion steering system is a critical component in modern vehicles, responsible for converting the rotational motion of the steering wheel into linear motion that turns the wheels. Over the years, the system has evolved significantly, driven by the need for improved efficiency, responsiveness, and safety. Early systems were mechanical, relying on direct linkages between the steering wheel and the rack. These systems, while functional, were often heavy and required significant effort to operate, especially at low speeds.

With advancements in automotive technology, power-assisted steering systems revolutionized the driving experience by reducing the effort required to steer and improving vehicle control. Today, the primary objective in developing rack and pinion steering systems is to enhance efficiency and responsiveness while minimizing energy consumption and environmental impact. Innovations in materials, manufacturing processes, and electronic controls, such as electric power steering (EPS), have been instrumental in achieving these goals. Additionally, improving steering feel and responsiveness through advanced control algorithms and sensor integration is a key focus, particularly as vehicles increasingly incorporate advanced driver assistance systems (ADAS) and autonomous driving technologies.

To get detailed scientific explanations of rack and pinion steering, try Patsnap Eureka TechResearch.

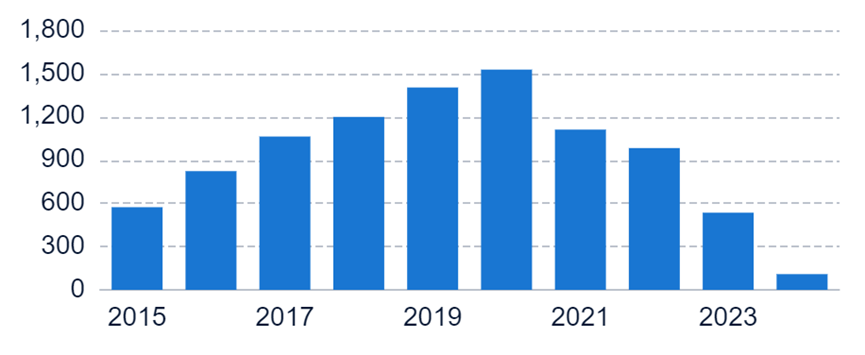

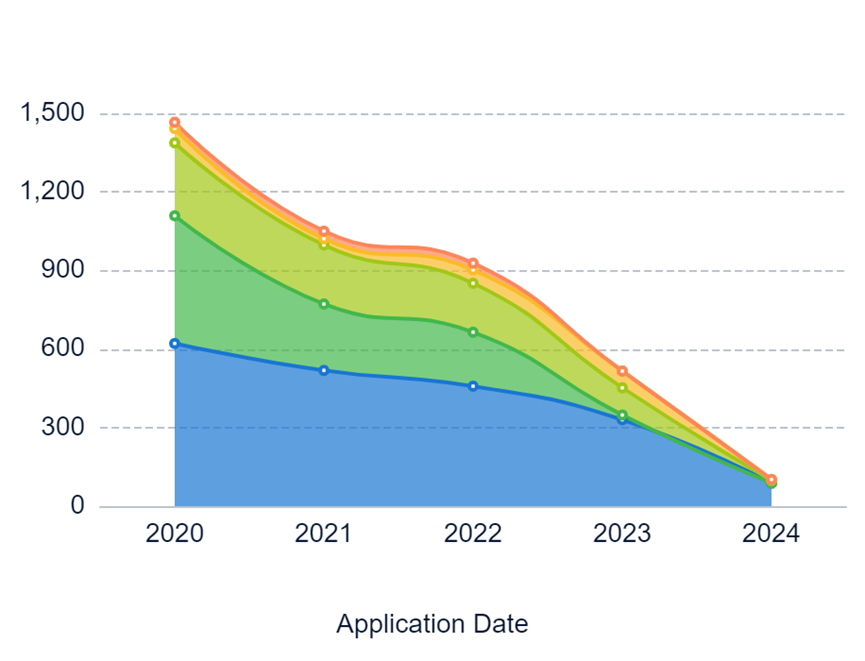

Market Demand for Efficient Steering Systems

The demand for efficient steering systems has grown steadily, driven by the automotive industry’s focus on improving fuel efficiency and reducing emissions.

Impact of Electrification and Autonomous Vehicles

- The increasing popularity of electric and hybrid vehicles has heightened the need for steering systems that are compatible with these powertrain technologies. Electric power steering (EPS) systems, which are more energy-efficient than traditional hydraulic systems, have become more prevalent.

Advanced Driver Assistance Systems (ADAS)

- The rise of ADAS and autonomous driving technologies underscores the importance of precise and responsive steering systems. As these technologies evolve, steering systems must meet higher standards of accuracy and reliability.

Other Sectors and Market Growth

- Beyond the automotive sector, the construction and agricultural equipment industries also demand efficient steering systems to improve maneuverability, reduce operator fatigue, and increase productivity. Market analysts predict continued growth in the global market for efficient steering systems, driven by stricter emissions regulations and the increasing adoption of electric and autonomous vehicles.

Current State and Challenges in Rack and Pinion Technology

Rack and pinion steering systems are widely adopted for their compact design, precise control, and relatively low manufacturing costs. However, as vehicles grow larger and heavier, these systems face challenges that can affect efficiency and safety.

Friction and System Efficiency

- One of the primary challenges is reducing friction within the system, which arises from various sources such as the sliding contact between gears, seals, and bearings. Excessive friction can reduce efficiency and lead to premature wear, compromising the system’s reliability.

Balancing Efficiency with Responsiveness

- Improving efficiency often involves reducing friction, but this can negatively impact steering responsiveness and feel, which are critical for driver control.

Impact of Electrification and Environmental Factors

- The integration of electric power steering (EPS) systems introduces additional complexities, as their efficiency depends on the seamless integration of electrical and mechanical components. Environmental conditions, such as extreme temperatures, can also affect the performance and durability of the system’s components, posing further challenges.

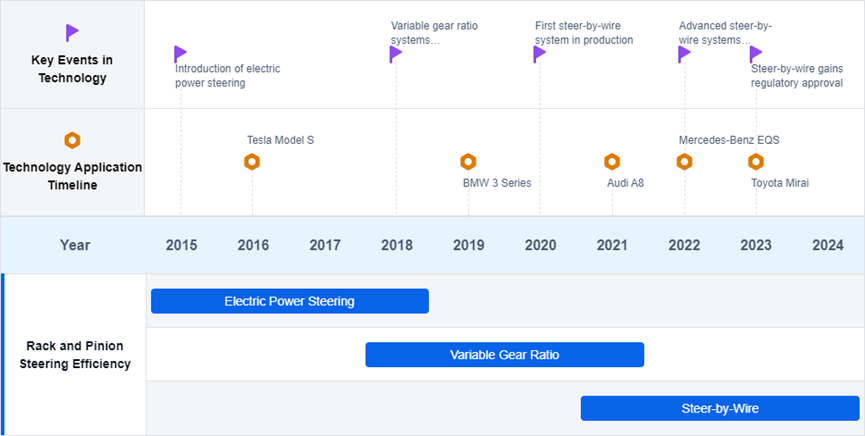

Evolution Path of Steering Mechanisms

Current Solutions for Rack and Pinion Efficiency

Rack and Pinion Steering Gear Design

The design of rack and pinion steering gears has seen various improvements, including variable ratio designs, power-assisted designs, and those aimed at reducing friction and improving efficiency.

Optimized Gear Ratios and Lightweight Materials

By optimizing gear ratios, reducing friction, and using lightweight materials, the efficiency of these systems can be significantly enhanced. Techniques such as variable gear ratios and advanced bearing designs contribute to increased efficiency and durability.

Enhanced Steering Feel and Compact Design

Efforts to improve steering feel and responsiveness involve optimizing gear geometry, reducing backlash, and incorporating feedback mechanisms. Compact and lightweight designs further enhance vehicle efficiency and handling.

Key Players in Steering System Industry

The competitive landscape for improving the efficiency of rack and pinion steering systems includes leading companies and emerging players making significant advancements.

ZF Automotive Germany GmbH

ZF Automotive Germany GmbH has developed an advanced rack and pinion steering system that incorporates electric power assistance. This system enhances steering precision and reduces driver effort, especially at low speeds, with real-time adjustments improving vehicle handling and safety.

Steering Solutions IP Holding Corp.

Steering Solutions IP Holding Corp. offers a hydraulic-assisted rack and pinion steering system that provides robust performance and reliability, particularly in heavy-duty applications. The hydraulic assistance ensures consistent steering effort across various driving conditions.

Hyundai Mobis Co. Ltd.

Hyundai Mobis Co. Ltd. has introduced a hybrid rack and pinion steering system combining electric and hydraulic assistance. This hybrid approach enhances steering feel and reduces energy consumption, optimizing performance based on driving conditions.

JTEKT Corp.

JTEKT Corp. offers an electric power-assisted rack and pinion steering system focused on energy efficiency and lightweight design. The system uses a compact electric motor to provide steering assistance, reducing overall vehicle weight and improving fuel efficiency.

Robert Bosch GmbH

Robert Bosch GmbH has developed an innovative rack and pinion steering system integrated with advanced driver assistance systems (ADAS). This system not only improves steering efficiency but also supports features like lane-keeping assistance and automated parking, enhancing overall vehicle safety and comfort.

Core Innovations in Steering Technology

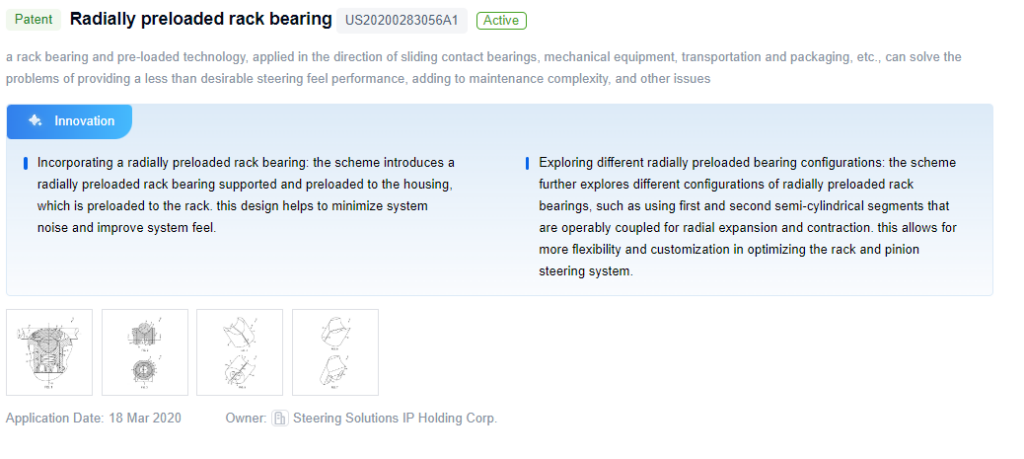

Patent 1: Radially Preloaded Rack Bearing

Key Points:

- This invention introduces a radially preloaded rack bearing that minimizes system noise and improves steering feel by preloading the bearing to the housing and rack.

- It explores different configurations of radially preloaded bearings, allowing for more flexibility and customization in optimizing the rack and pinion steering system.

Patent 2: Augmented Rack and Pinion Steering System

Key Points:

- The system eliminates the need for concerted motion between the draglink and suspension link by directly attaching the rack and pinion gearset to the front solid axle.

- A slip-joint on the steering shaft improves precision and responsiveness in the steering system.

Paper 1: Design and Development of Rack and Pinion Steering Gear Assembly for Passenger Car Vehicle

Key Points:

- This paper covers the design and development of a rack and pinion steering gear assembly, including gear calculations, performance simulations, and experimental testing.

- It discusses design parameters like gear ratio and pinion shaft angle, along with CAD modeling and stress analysis.

Potential Innovations in Rack and Pinion Systems

Optimized Gear Design

Efficiency can be enhanced by optimizing gear design, including tooth profiles and material selection, to reduce friction and energy losses.

Variable Gear Ratio Mechanisms

Incorporating variable gear ratio mechanisms can improve efficiency by adjusting the gear ratio based on steering input, optimizing steering effort for different driving conditions.

Power Assistance Integration

Integrating power assistance mechanisms, such as hydraulic or electric systems, can reduce driver effort and improve overall steering efficiency, particularly in low-speed maneuvers.

Regulatory Landscape for Automotive Steering Systems

The regulatory landscape for automotive steering systems is governed by national and international standards that ensure safety, reliability, and environmental sustainability. Key regulations include UNECE Regulation No. 79 and FMVSS standards in the United States, which set specific requirements for steering systems. Compliance with these regulations is critical for manufacturers, as failure to adhere can result in legal and financial consequences.

Environmental Impact of Steering System Technologies

Steering system technologies have environmental impacts that must be addressed to promote sustainability. Conventional systems consume significant energy and involve materials that may contribute to resource depletion and pollution. Innovations such as electric power steering (EPS), lightweight materials, and advanced control algorithms can reduce energy consumption and environmental impact. Additionally, designing for recyclability and responsible end-of-life management are crucial for minimizing environmental impact and promoting a circular economy in the automotive industry.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!