- Deep dive into all technical problems

- Define your research direction

- Monitor your competitors and tech landscape

- More AI-powered features

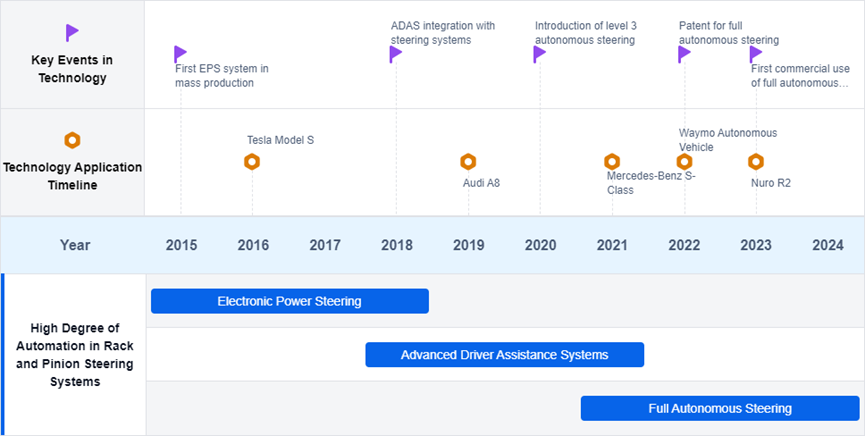

Automation Goals in Rack and Pinion Steering

Achieving high automation in rack and pinion steering systems is crucial for enhancing vehicle safety and driving comfort, while also enabling autonomous driving technologies. The primary objective is to develop advanced control systems that seamlessly integrate sensors, actuators, and computational units, thereby enabling precise and responsive steering control with minimal human intervention.

Key Areas of Automation

- Assisted Steering: Focuses on reducing the driver’s physical effort by providing hydraulic or electric power assistance.

- Active Steering: Actively adjusts the steering angle based on vehicle dynamics and driving conditions, enhancing stability and responsiveness.

- Autonomous Steering: Aims for complete automation, enabling self-driving capabilities.

Technological Integration

- Advanced Sensors: Essential for perceiving surroundings and detecting obstacles, lane markings, and other relevant information.

- Sophisticated Control Algorithms: Required to process sensor data, interpret driving conditions, and generate appropriate steering commands.

- High-Precision Actuators: Needed to execute desired steering actions accurately and reliably.

To get detailed scientific explanations of rack and pinion steering, try Patsnap Eureka TechResearch.

Market Demand for Automated Steering Systems

The demand for automated steering systems is driven by safety enhancements, fuel efficiency, and the rise of autonomous vehicles.

- Enhanced Safety: Automated steering systems help prevent accidents caused by driver inattention or fatigue, improving road safety.

- Autonomous Vehicles: The need for precise steering control is critical as vehicles progress towards higher levels of autonomy.

- Fuel Efficiency: Automated systems optimize vehicle dynamics, contributing to better fuel efficiency and emission reduction.

- Commercial Applications: In the commercial sector, automated systems are in demand for applications such as platooning and advanced driver assistance systems (ADAS), enhancing operational efficiency and reducing driver fatigue.

- Agricultural Sector: Automated steering systems improve precision farming, enhancing crop yields, reducing input costs, and minimizing environmental impact.

Current State and Challenges in Rack and Pinion Automation

Achieving automation in rack and pinion steering systems presents several challenges:

Precise Control and Coordination

- System Complexity: The rack and pinion system consists of intricate mechanical parts that must work in harmony for smooth steering. Advanced sensors, robust control algorithms, and high-performance actuators are required to achieve real-time synchronization.

Integration with ADAS

- Seamless Integration: Integrating advanced driver assistance systems with rack and pinion mechanisms demands sophisticated software and hardware architectures. Ensuring reliable and safe operation under various driving conditions is critical.

Harsh Operating Environments

- Durability and Reliability: Rack and pinion systems are exposed to extreme temperatures, vibrations, and potential contaminants. Developing robust components that maintain precision and responsiveness is essential.

Geographical Factors

- Regional Variations: Different regions have varying regulatory requirements, infrastructure conditions, and driving patterns, influencing the design and implementation of automated systems.

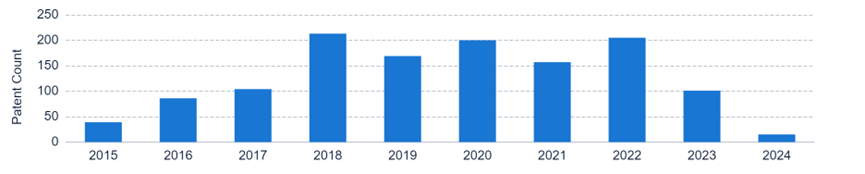

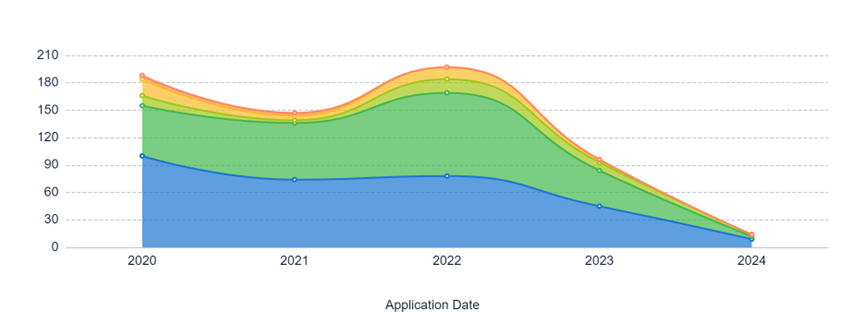

Evolution of Steering System Automation

Existing Solutions for Automated Rack and Pinion Systems

Variable Gear Ratio Mechanisms

These mechanisms adjust the steering ratio based on vehicle speed or steering angle, improving responsiveness and control in different driving conditions.

Power-Assisted Steering Systems

Power assistance, typically hydraulic or electric, reduces driver effort, enhancing maneuverability at low speeds or during parking.

Integrated Sensors and Control Systems

Advanced systems incorporate sensors and electronic control units to monitor and adjust steering behavior, enabling features like variable assist and stability control.

Durability and Reliability Enhancements

Improved sealing mechanisms, wear-resistant components, and robust housing designs enhance the durability and reliability of steering systems.

Compact and Lightweight Design

Efforts are made to reduce the size and weight of steering systems while maintaining performance, making them suitable for vehicles where space and weight are critical.

Improved Steering Feel and Feedback

Techniques such as optimizing gear ratios, reducing friction, and incorporating feedback mechanisms enhance the steering feel and feedback to the driver.

Key Players in Steering System Automation

The competitive landscape for achieving a high degree of automation in rack and pinion steering systems is shaped by industry growth, market size, and technology maturity.

Robert Bosch GmbH

Bosch has developed an advanced rack and pinion steering system with high automation capabilities, integrating electric power steering (EPS) with advanced driver-assistance systems (ADAS) to enhance precision and control.

Steering Solutions IP Holding Corp.

Steering Solutions offers a semi-automated steering system utilizing electronic control units (ECUs) to manage steering dynamics, focusing on improving driver comfort and reducing steering effort.

ZF Automotive Germany GmbH

ZF Automotive introduced a fully automated steering system incorporating steer-by-wire technology, eliminating the mechanical connection between the steering wheel and the wheels for improved safety and flexibility.

Continental Automotive Systems Inc.

Continental has developed an intelligent steering system using sensor fusion and real-time data processing, designed to work seamlessly with autonomous driving technologies.

JTEKT Corp.

JTEKT offers an advanced steering system with a focus on electric power steering (EPS) and automation, integrating torque sensors and electronic control units for precise steering control.

Core Innovations in Steering System Automation

Patent 1: Rack and Pinion Type Steering System

Key Points:

- Providing a rack and pinion type steering apparatus with a pinion shaft connected to a steering shaft and having a pinion gear.

- A rack bar with a rack gear meshing with the pinion gear and connected to tie rods via inner ball joints.

- A rack housing fixed to the vehicle body accommodating the sliding movement of the rack bar.

Patent 2: Rack and Pinion Type Steering System

Key Points:

- Rack and pinion type steering system with a rack bar, rack housing, pinion shaft, and tie-rod for efficient steering control.

- The rack bar has a rack gear engaged with a pinion gear on the pinion shaft allowing for smooth gear-based steering motion.

- The tie-rod is coupled to the end of the rack bar via an inner ball housing enabling precise steering angle transmission.

Paper 1: Practical Examples of System Automation and Control

Key Points:

- The chapter presents practical guided approaches for system automation by integrating sensors, controllers, and actuators with minimal human interference.

- Examples include the automation of irrigation systems, waste segregators, gasifiers, biodiesel plants, biogas plants, lawn mowers, assembly lines, and railcar suspension systems.

Potential Breakthroughs in Steering Automation

Automated Control Systems

Various control systems and methods have been developed to automate the operation of rack and pinion steering systems, enabling self-driving capabilities and adjusting steering angles based on driving conditions.

Sensor Integration

Incorporating sensors in steering systems provides feedback on position, speed, and torque, crucial for automated control and advanced driver assistance systems.

Variable Gear Ratios

Variable gear ratio systems adjust based on driving conditions or user preferences, improving steering responsiveness and control.

Power-Assisted Systems for Automation

Integrating power-assisted steering with automated control systems provides the necessary torque for steering maneuvers, particularly in larger vehicles or at low speeds.

Regulatory Landscape for Automated Steering Systems

The development of highly automated steering systems is governed by a complex regulatory landscape encompassing national and international standards. Key regulations include the UNECE framework and NHTSA guidelines, which set standards for safety, reliability, and performance in automated driving systems. Manufacturers must closely monitor and comply with these evolving regulations to ensure successful deployment.

Environmental Impact of Automated Steering Technologies

Automated steering technologies offer potential benefits like improved fuel efficiency and reduced emissions, but also pose environmental concerns during manufacturing and disposal phases. Complex electronic components have a significant environmental footprint. The widespread adoption of these technologies could increase vehicle usage, potentially offsetting emissions reductions. Sustainable practices in manufacturing, energy use, and recycling are essential to mitigate negative impacts.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!