Technology Background and Objectives

Rack and pinion steering systems are widely used in modern vehicles due to their compact design, precise steering control, and relatively low maintenance requirements. However, noise generation remains a significant challenge, stemming from factors such as gear meshing, bearing vibrations, and friction between components. Reducing noise in these systems has become an essential goal for automotive manufacturers, as it directly impacts driving comfort, passenger satisfaction, and overall vehicle quality.

The drive for quieter steering systems is fueled by stringent noise regulations, growing consumer expectations for a refined driving experience, and the increasing demand for premium and luxury vehicles. Achieving these objectives involves understanding noise sources, developing innovative materials and design solutions, and implementing effective noise-cancellation techniques. Key areas of focus include optimizing gear tooth profiles, advanced bearing designs, and the use of noise-damping materials. Additionally, active noise control systems, which use counteracting sound waves to cancel out unwanted noise, are being explored as potential solutions.

To get detailed scientific explanations of rack and pinion steering, try Patsnap Eureka TechResearch.

Market Demand Analysis

The market demand for noise reduction technologies in rack and pinion steering systems is growing due to several factors:

- Consumer Expectations: In premium and luxury vehicle segments, customers seek quieter, more refined cabin environments. Reducing steering system noise contributes to a better driving experience.

- Stricter Regulations: Governments and regulatory bodies are enforcing stricter noise regulations, requiring automakers to address noise issues more proactively. Excessive noise levels contribute to environmental pollution and pose potential health risks over time.

- Electrification and Noise Concerns: The shift towards electrification has highlighted noise reduction as a crucial aspect of steering system design. Electric motors and gears can produce high-frequency noises, which may be perceived as unpleasant by vehicle occupants.

In commercial vehicles and heavy-duty trucks, reducing noise levels can improve driver comfort and reduce fatigue, leading to increased productivity and safety. Market research indicates that the global automotive noise, vibration, and harshness (NVH) materials market, which includes solutions for steering system noise reduction, is expected to grow significantly in the coming years. This growth is driven by the demand for premium vehicles, stricter regulations, and the adoption of advanced technologies such as electric power steering systems.

Current State and Challenges

Reducing noise in rack and pinion steering systems presents several challenges:

- System Design: The inherent design involves multiple moving parts that generate noise due to friction, vibration, and mechanical interactions. The meshing of the pinion gear with the rack and the sliding motion of the rack within its housing are major sources of noise. Additionally, road surface vibrations can amplify noise levels.

- Material Constraints: Traditional materials like steel and aluminum, while durable, contribute to noise due to their rigidity and poor damping properties. This necessitates exploring alternative materials or incorporating noise-damping coatings or insulation.

- System Integration: The integration of the steering system with other vehicle components, such as suspension and chassis, can exacerbate noise issues. Vibrations and resonances can propagate through the vehicle structure, leading to increased cabin noise.

Geographical factors also influence noise challenges, as road conditions, driving styles, and environmental factors vary across regions. Addressing these challenges requires a comprehensive understanding of local conditions and tailored solutions. Furthermore, the increasing demand for electric and autonomous vehicles introduces new noise reduction challenges, as electric power steering systems, while eliminating some noise sources, may introduce new ones related to electric motors and control systems. Achieving quieter steering systems demands a multidisciplinary approach, incorporating expertise in materials science, vibration analysis, acoustics, and system integration.

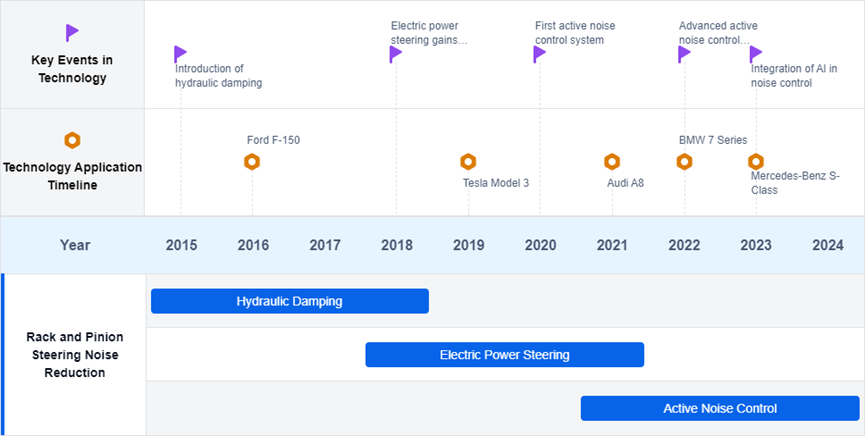

Technology Evolution Path

Current Technical Solutions

Rack and Pinion Steering Gear Design for Noise Reduction

Design improvements in rack and pinion steering gear focus on using specific materials, coatings, and surface treatments to minimize friction and vibration. Additionally, gear geometry and tooth profiles are optimized to reduce noise generation.

Noise-Damping Components in Steering Systems

Incorporating noise-damping materials, such as rubber bushings or vibration-damping shims, within the steering gear assembly helps absorb or isolate vibrations, thereby reducing noise.

Variable Ratio Rack and Pinion Steering Gear

Variable ratio steering gears are designed to optimize gear ratios at different steering angles, reducing noise, particularly during tight turns or under high load conditions.

Key Players Analysis

The competitive landscape for noise reduction in rack and pinion steering systems is shaped by several key players in the industry.

HL Mando Co. Ltd.

HL Mando has developed advanced noise reduction technology for rack and pinion steering systems, utilizing high-precision gears and advanced damping materials to minimize noise and vibration. Their technology also includes a real-time monitoring system to detect and adjust for anomalies.

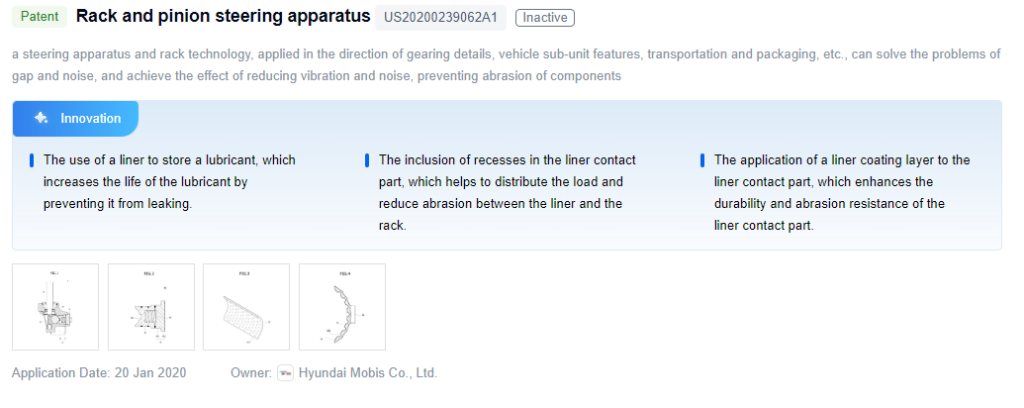

Hyundai Mobis Co. Ltd.

Hyundai Mobis offers a noise reduction solution that combines acoustic insulation materials with optimized gear design. Their approach focuses on reducing noise transmission through the steering column, enhancing the overall driving experience.

Steering Solutions IP Holding Corp.

Steering Solutions has introduced noise reduction technology using advanced lubrication techniques and precision-engineered components. Their solution aims to reduce friction and wear, thereby minimizing noise in rack and pinion steering systems.

NSK Ltd.

NSK has developed noise reduction technology for steering systems that employs high-performance bearings and vibration-damping materials. Their solution is designed to enhance the smoothness of steering operation and significantly reduce noise levels.

Turntide Technologies Inc.

Turntide Technologies offers an innovative noise reduction solution for steering systems that leverages smart motor technology and advanced control algorithms. Their approach focuses on optimizing motor performance to minimize noise and improve efficiency.

Key Technology Interpretation

Patent 1: Rack and Pinion Steering Apparatus

Key Points:

- The use of a liner to store a lubricant increases lubricant life by preventing leaks.

- Recesses in the liner contact part help distribute the load and reduce abrasion between the liner and the rack.

- A liner coating layer enhances the durability and abrasion resistance of the liner contact part.

Patent 2: Wedge Adjuster Plug

Key Points:

- A non-metallic rack bearing material reduces noise and vibration.

- The adjuster plug design improves engagement with the rack housing bore, minimizing noise during operation.

Paper 1: Assessment of Ambient Noise Levels in Urban Residential Streets

Key Points:

- Surface modification of brake discs through grit blasting reduces noise generation, though the silencing effect is limited by wear.

Paper 2: Surface Modification of Brake Discs to Reduce Squeal Problems

Key Points:

- The study recommended remedial actions to reduce noise levels but did not specify any particular innovation or solution.

Potential Innovation Directions

Noise-Damping Components in Steering Systems

Incorporating noise-damping materials and specific designs in the rack and pinion system can effectively reduce noise and vibration. These may include damping bushings or specialized structures in the rack housing.

Optimized Gear Design

Optimizing gear design, including tooth profiles and material selection, can reduce noise and vibration during operation.

Improved Lubrication

Proper lubrication using specialized lubricants or lubrication systems can minimize friction, reducing noise and extending the life of steering components.

Vibration Isolation Techniques

Employing vibration isolation techniques can prevent the transmission of noise and vibrations from the steering system to the vehicle body, improving overall vehicle refinement.

Regulatory and Compliance Considerations

Regulatory and compliance considerations are crucial in developing noise reduction technologies for rack and pinion steering systems. Compliance with noise emission regulations, such as those established by environmental protection agencies, is essential to limit vehicle noise levels. Additionally, these technologies must adhere to safety standards set by bodies like the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP).

Moreover, the materials and processes used in these technologies must comply with environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Intellectual property rights, maintainability, and comprehensive documentation are also vital considerations.

Environmental Impact and Sustainability

Environmental impact and sustainability are key considerations in developing noise reduction technologies for rack and pinion steering systems. Eco-friendly lubricants, optimized manufacturing processes, and sustainable materials are essential to minimize the environmental footprint. Noise reduction technologies should be designed for recyclability, with a focus on improving fuel efficiency and reducing emissions. Awareness and education among stakeholders are also crucial for promoting environmental sustainability in the automotive industry.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!