Technical Background and Objectives

Background

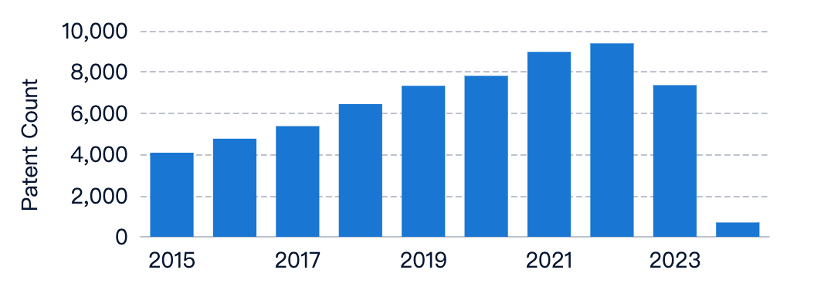

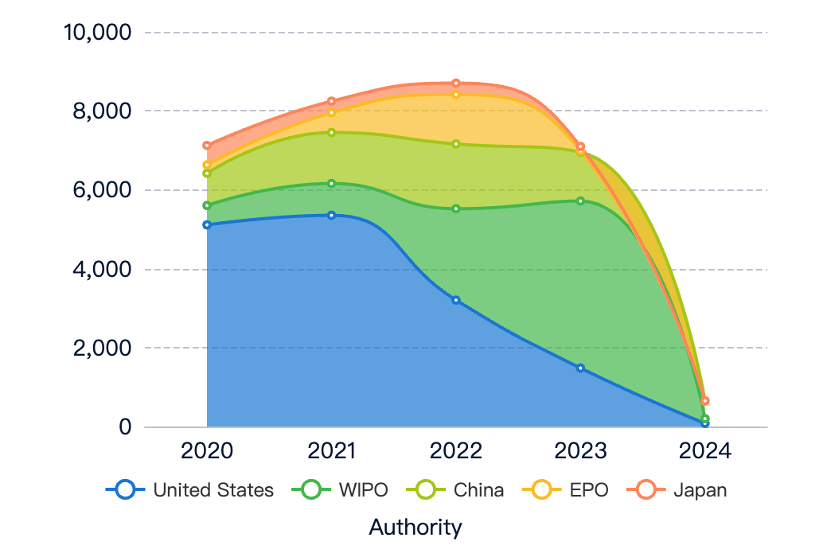

Reducing the weight of end effectors has emerged as a significant technological trend. The patent application data shows a consistent year-over-year increase, indicating sustained research and development efforts aimed at achieving lighter-weight end effector designs. This upward trajectory suggests that the industry recognizes the importance of weight reduction for end effectors, potentially driven by factors such as improved efficiency, reduced energy consumption, and enhanced maneuverability. However, literature data presents fluctuations, indicating periodic shifts in academic research focus or funding priorities. The consistent rise in patent filings implies significant potential in lightweight end effector designs, driven by improved operational efficiency, reduced energy consumption, and enhanced maneuverability in various applications.

Objectives

The primary objective is to explore and develop innovative solutions for reducing the weight of end effectors used in robotic systems. By reducing their weight, we aim to improve energy efficiency, increase payload capacity, and enhance maneuverability, ultimately expanding the range of applications for robotic systems.

To get a detailed scientific explanations of End Effector, try Eureka.

Technical Current Status Analysis

End Effectors Overview

End effectors are essential components of robotic systems, serving as the interface between the robot and the environment or workpiece. They are designed to perform specific tasks such as gripping, welding, cutting, or assembly operations. Reducing the weight of end effectors is crucial for improving the overall performance and efficiency of the robotic system.

Applications and Impact:

- Automotive Industry: Used for handling and positioning components on assembly lines, where reduced weight allows for faster and more precise movements.

- Aerospace Industry: Essential for manufacturing and maintenance operations, where reduced weight improves payload capacity and maneuverability.

- Medical and Healthcare Sectors: Beneficial for robotic-assisted surgical procedures and rehabilitation applications, minimizing fatigue and strain.

- Electronics and Semiconductor Industries: Employed in pick-and-place operations and precision assembly tasks, where reduced weight contributes to higher accuracy and throughput.

Technical Characteristics and Challenges:

- Material Selection: Choosing lightweight yet strong and durable materials is crucial. Advanced materials like carbon fiber reinforced polymers, aluminum alloys, or titanium alloys offer high strength-to-weight ratios but may be more expensive or require specialized manufacturing processes.

- Structural Optimization: Techniques like topology optimization, finite element analysis, and additive manufacturing can help reduce weight while maintaining strength and stiffness.

- Actuation and Transmission Systems: Exploring lightweight actuation technologies and efficient transmission mechanisms can help reduce weight.

- Sensor Integration: Integrating lightweight sensor technologies and minimizing the weight of associated electronics and wiring.

- Thermal Management: Lightweight heat dissipation solutions are required for optimal performance and reliability.

- Modularity and Reconfigurability: Achieving weight reduction while maintaining modularity and flexibility.

Technological Paths:

- Advanced Lightweight Materials: Continuous research in materials such as carbon fiber reinforced polymers, metal matrix composites, or high-strength aluminum alloys.

- Topology Optimization and Additive Manufacturing: Leveraging topology optimization techniques and 3D printing for optimized end effector structures.

- Lightweight Actuation and Transmission Systems: Developing and integrating lightweight actuation technologies and efficient transmission mechanisms.

- Miniaturized and Integrated Sensor Technologies: Exploring miniaturized sensor technologies such as MEMS-based sensors or compact vision systems.

- Advanced Thermal Management Solutions: Investigating lightweight and efficient thermal management solutions.

- Modular and Reconfigurable Design Approaches: Developing designs that allow for easy adaptation to different tasks while minimizing weight.

Research Content

Research Objectives

Explore and develop innovative solutions for reducing the weight of end effectors used in robotic systems.

Research Direction and Focus

Materials and Design Optimization

- Investigate advanced lightweight materials and optimized structural designs.

- Use topological optimization algorithms and finite element analysis to optimize the design for maximum strength-to-weight ratio.

Actuation and Transmission Mechanisms

- Explore novel actuation and transmission mechanisms, including smart materials and miniaturized motors.

- Integrate efficient power transmission systems such as cable-driven or compliant mechanisms.

Sensor Integration and Control Strategies

- Investigate lightweight and low-power sensor technologies such as fiber-optic sensors or MEMS-based sensors.

- Develop advanced control algorithms and strategies to optimize performance and minimize energy consumption.

Technical Development Roadmap

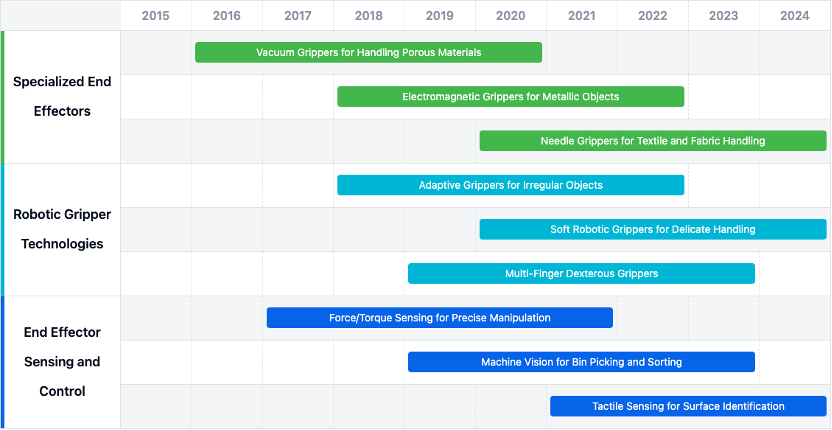

Key Areas of Advancement

- Robotic Gripper Technologies: Adaptive grippers, soft robotic grippers, and multi-finger dexterous grippers.

- End Effector Sensing and Control: Force/torque sensing, machine vision, and tactile sensing.

- Specialized End Effectors: Vacuum grippers, electromagnetic grippers, and needle grippers for specific applications.

Main Player Analysis

Key Players and Focus

- Tehran University of Medical Sciences: Research on natural extracts, supplements, and dietary interventions, contributing to lightweight materials or coatings for end effectors.

- Islamic Azad University: Research on nanoparticles, essential oils, and natural extracts for lightweight and functional coatings or materials.

- Monsanto Technology LLC: Expertise in agricultural solutions contributing to lightweight and efficient end effectors for agricultural applications.

- Pioneer Hi-Bred International Inc.: Advanced seed products and agricultural technologies for lightweight end effectors in precision agriculture.

- Genentech Inc.: Biotechnologies for lightweight and efficient end effectors in biomedical or pharmaceutical applications.

Current Technical Solution Overview

Weight Reduction Techniques for End Effectors

- Robotic End Effectors: Using lightweight materials, optimized design, or integration of weight reduction mechanisms.

- Medical Devices and Prosthetics: Improving patient comfort and mobility through lightweight materials and optimized designs.

- Automotive Components: Enhancing fuel efficiency and performance with lightweight materials and designs.

- Neural Networks and Computational Systems: Optimizing performance with reduced weights or connections in neural networks.

Weight-Reducing Compositions and Compounds

- Natural Plant Extracts or Herbal Ingredients: Promoting weight loss or preventing weight gain through synergistic effects.

- Probiotics or Dietary Fibers: Modulating gut health and regulating metabolism.

- Pharmaceutical Compositions: Targeting metabolic pathways for weight regulation.

- Traditional Chinese Medicine Compositions: Combining herbs and natural ingredients for weight management.

- Compositions with Combined Effects: Promoting weight loss while providing additional health benefits.

Weight Management Devices and Systems

- Smart Weighing Scales: Tracking body weight and providing personalized recommendations.

- Exercise and Activity Tracking: Monitoring physical activity and providing personalized exercise plans.

- Dietary Intake Monitoring: Tracking dietary intake and offering meal planning suggestions.

- Behavioral Modification Techniques: Encouraging sustainable lifestyle changes.

- Systems for Specific Populations: Tailored weight management solutions for unique needs.

Weight Reduction Through Dietary Interventions

- Dietary Supplements: Formulated with natural extracts or compounds to promote weight loss.

- Dietary Fiber Compositions: Regulating blood sugar levels and reducing calorie absorption.

- Meal Replacement or Supplement Powders: Reducing calorie intake and promoting weight management.

- Personalized Weight Management Methods: Comprehensive dietary plans and nutritional compositions.

- Lipid-Binding or Appetite-Regulating Compositions: Reducing dietary fat absorption and controlling appetite.

Weight Reduction Through Physical or Mechanical Means

- Physical Exercise: Devices and methods for active training.

- Mechanical Devices: Techniques for reducing effective weight during exercise or rehabilitation.

- Monitoring and Simulation: Tracking weight reduction progress and providing feedback.

- Physical and Mental Interventions: Combining physical exercise with mental conditioning.

- Dietary and Compound Interventions: Compositions targeting metabolic and physiological processes.

Key Patent Interpretation

Patent Highlights

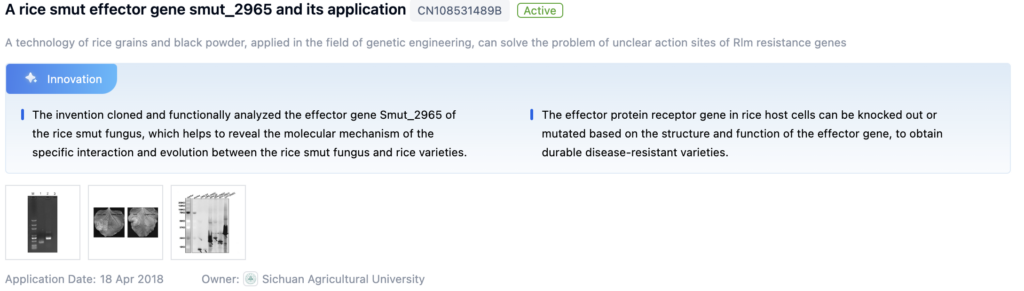

Patent 1: A Rice Smut Effector Gene SMUT_2965 and Its Application

- Core Invention Points:

- Cloning and functional analysis of the effector gene SMUT_2965.

- Revealing molecular interactions and evolution between rice smut fungus and rice varieties.

- Developing disease-resistant rice varieties through gene manipulation.

Patent 2: A Rice Smut Effector Gene SMUT_5844 and Its Application

- Core Invention Points:

- Cloning and functional analysis of the effector gene SMUT_5844.

- Designing new agricultural pesticides based on effector gene structure and function.

- Developing disease-resistant rice varieties through gene manipulation.

Patent 3: Telesurgical System with Intrinsic Haptic Feedback

- Core Invention Points:

- Generating pseudo-haptic feedback without integrating an actuator in the user interface.

- Reducing the need for sophisticated force sensor systems.

- Utilizing visual feedback for user perception.

Possible Research Directions

- Lightweight Materials for End Effectors: Using advanced materials like carbon fiber or composites to reduce weight.

- Optimized Design for Weight Reduction: Employing topology optimization and finite element analysis.

- Weight Compensation Mechanisms: Incorporating counterweights or active force control systems.

- Modular and Reconfigurable End Effectors: Designing flexible components for different tasks.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!