AGM Battery Charging Challenges and Goals

AGM (Absorbed Glass Mat) batteries are widely used in various applications, including automotive, marine, and renewable energy systems. One of the key challenges associated with AGM battery is the relatively long charging time of AGM battery compared to other battery technologies. This issue can lead to inconvenience, reduced operational efficiency, and potential downtime in critical applications.

The primary goal is to develop innovative solutions that can significantly reduce the charging time of AGM batteries without compromising their performance, safety, or lifespan. Achieving this goal would enhance user experience, improve productivity, and potentially open up new applications where rapid charging is essential.

Several factors contribute to the longer charging time of AGM batteries, including their unique construction, internal resistance, and the need for controlled charging to prevent overheating and potential damage. Overcoming these challenges requires a multifaceted approach that combines advancements in battery chemistry, charging algorithms, and charging infrastructure.

Potential solutions may involve optimizing the battery’s internal design, exploring new electrolyte compositions, or incorporating advanced materials that facilitate faster charge acceptance. Additionally, intelligent charging algorithms that dynamically adjust charging parameters based on battery conditions and state of charge could be developed. Furthermore, integrating high-power charging infrastructure and exploring alternative charging methods, such as pulse charging or ultracapacitor-assisted charging, could contribute to reducing charging time.

Ultimately, the goal is to achieve a significant reduction in charging time, ideally reaching levels comparable to or surpassing those of lithium-ion batteries, while maintaining the inherent advantages of AGM batteries, such as their robustness, safety, and low maintenance requirements.

To get a detailed scientific explanations of agm battery, try Eureka.

Market Demand for Fast-Charging AGM Batteries

The market demand for fast-charging AGM batteries is driven by several key factors:

- Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs): The increasing adoption of EVs and HEVs has created a significant need for efficient and reliable battery systems that can be charged quickly, minimizing downtime and maximizing operational efficiency.

- Renewable Energy Systems: The growing popularity of renewable energy systems, such as solar and wind power installations, has fueled the demand for energy storage solutions that can rapidly store and discharge energy, making fast-charging AGM batteries crucial.

- Backup Power Solutions: Reliable backup power is essential for sectors like telecommunications, data centers, and healthcare facilities, where continuous operations are critical, and fast-charging batteries provide a cost-effective solution.

Market analysts predict continued growth in the global AGM battery market, driven by increasing adoption in automotive, renewable energy, and backup power applications. The trend towards electrification and the growing emphasis on sustainability and energy efficiency further fuel the demand for fast-charging AGM batteries.

Current State and Limitations of AGM Battery Charging

Advancements in AGM battery technology have revolutionized energy storage, but long charging time remain a significant limitation. Contributing factors include:

- Internal Resistance: Higher internal resistance in AGM batteries due to the compressed design and glass mat separator leads to slower charge acceptance rates.

- Controlled Charging Process: AGM batteries require precise charging to prevent overcharging and potential damage, leading to slower charging time.

- Capacity Limitation: As battery capacity increases, the energy required to fully charge also increases, prolonging charging time.

- Thermal Management: Effective thermal management is crucial to prevent excessive heat generation during charging, which can degrade the battery and pose safety risks, further extending charging time.

Ongoing research focuses on innovative charging strategies, advanced battery management systems, and improved thermal management techniques to address these limitations.

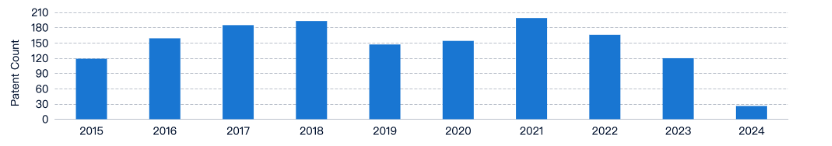

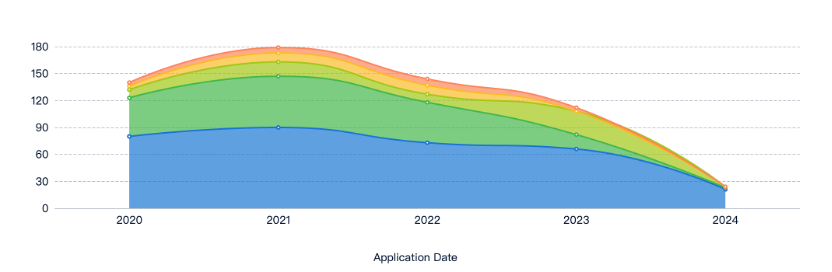

Evolution of AGM Battery Charging Technologies

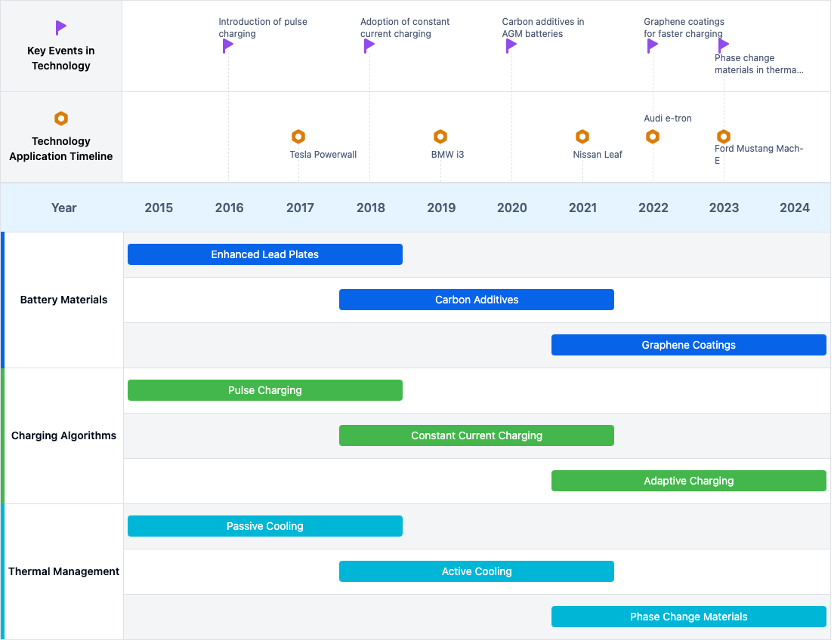

Existing Solutions for Reducing AGM Charging Time

AGM Battery Structure and Materials

Optimizing the structure and materials used in AGM batteries can affect charging time. This includes the design of the separator, grid, and other components, as well as the use of specialized materials like modified separators or enhanced electrolytes.

AGM Battery Separator Structure

The AGM battery separator plays a crucial role in performance and safety. Various separator structures, including those with through-holes and composite materials, improve electrolyte absorption, oxygen recombination efficiency, and thermal stability.

AGM Battery Formation and Manufacturing Processes

Various processes have been developed for AGM battery production, including electrolyte injection, container formation, and gel feeding. These processes aim to improve performance, efficiency, and quality control.

Charging Algorithms and Control Systems

Specialized charging algorithms and control systems optimize the charging process and reduce charging time for AGM batteries. Techniques may include smooth transitions between charging stages, balanced charging, or minimizing charge time.

Battery Monitoring and Diagnostics

Monitoring and diagnostic systems assess the state of the AGM battery during charging, allowing for optimized strategies and reduced charging time. Techniques include detecting separator saturation, electrolyte leakage, or oxygen recombination efficiency.

Specialized Battery Designs and Configurations

Certain battery designs and configurations can enhance AGM battery charging performance and reduce charging time, including start-stop battery designs, lead-carbon configurations, or specialized grid or separator designs.

Key Players in AGM Battery Industry

Fengfan Co. Ltd.

Developed advanced AGM battery technologies focusing on reducing charging time by optimizing internal resistance and enhancing electrolyte composition.

Daramic LLC

Offers separator technologies for AGM batteries that significantly reduce charging time by enhancing ion flow and reducing internal resistance.

Anhui Leoch Battery Technology Corp.

Focuses on high-performance AGM batteries with reduced charging time, utilizing advanced grid designs and optimized lead paste formulations.

Shuangdeng Group Co. Ltd.

Developed AGM batteries with rapid charging capabilities by improving the active material and employing advanced manufacturing techniques.

Iontra Inc.

Specializes in battery management systems that optimize the charging process of AGM batteries using advanced algorithms to manage charge rates and improve efficiency.

Core Innovations in AGM Battery Charging

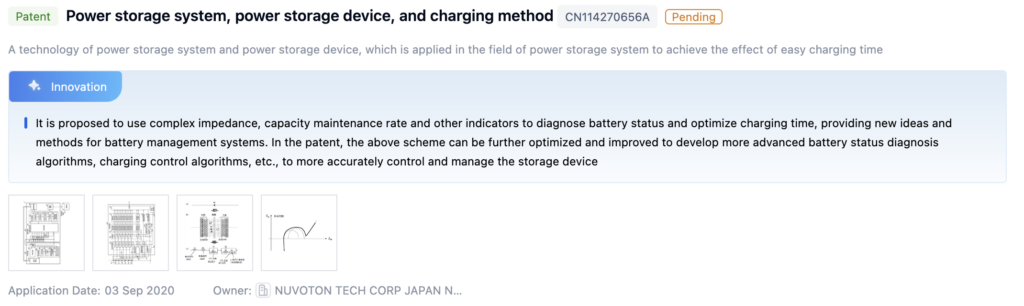

Patent 1: Power Storage System, Power Storage Device, and Charging Method

- Core Points:

- Uses complex impedance and capacity maintenance rate to diagnose battery status and optimize charging time, providing new ideas and methods for battery management systems.

- Proposed scheme for more advanced battery status diagnosis algorithms and charging control algorithms.

Patent 2: Charging Control Method and Charging Control Apparatus

- Core Points:

- Allows charging at a higher voltage level without causing overvoltage, resulting in increased charging speed.

- Monitors voltage thresholds to prevent overvoltage and uses current thresholds to gradually reduce charging current for more precise control and improved efficiency.

Potential Breakthroughs in AGM Battery Technology

Optimizing Battery Charging Algorithms

Techniques such as pulse charging, multi-stage charging, or adaptive charging based on battery parameters can optimize charging algorithms for faster and more efficient charging.

Improving Battery Design and Materials

Advancements in electrode composition, separator materials, or electrolyte formulations can enhance charge acceptance and reduce internal resistance, contributing to reduced charging time.

Monitoring and Control Systems

Implementing monitoring and control systems that adjust charging parameters based on battery conditions can optimize the charging process and minimize charging time while preventing overcharging or damage.

Thermal Management Techniques

Effective thermal management, such as active cooling or heating systems, can maintain the battery within an optimal temperature range, improving charge acceptance and reducing charging time.

Regulatory Landscape for Battery Charging Technologies

The regulatory landscape for battery charging technologies includes various standards and guidelines to ensure safety, efficiency, and environmental sustainability. Key considerations include electrical safety, thermal management, environmental regulations, energy efficiency, and interoperability standards.

Environmental Impact of AGM Battery Charging

The environmental impact of AGM battery charging includes energy consumption during the charging cycle, battery degradation due to improper charging practices, and the environmental implications of the materials used. Strategies to address these concerns include optimizing charging algorithms, integrating renewable energy sources, implementing energy-efficient charging infrastructure, and promoting responsible recycling and disposal practices.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!