Technical Background and Objectives

Reducing power consumption in cabin air filters is essential across industries like automotive, aerospace, and HVAC systems. These filters are crucial for maintaining indoor air quality but often rely on high-power fans, leading to significant energy use. With rising environmental concerns and energy costs, there’s a need for solutions that balance air quality with energy efficiency.

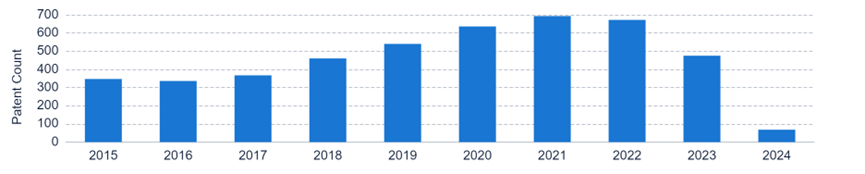

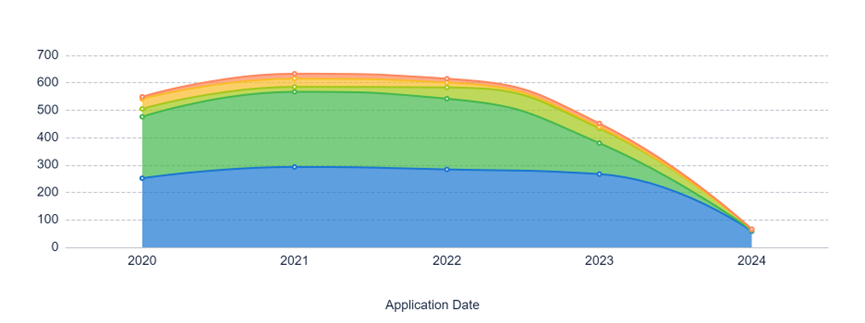

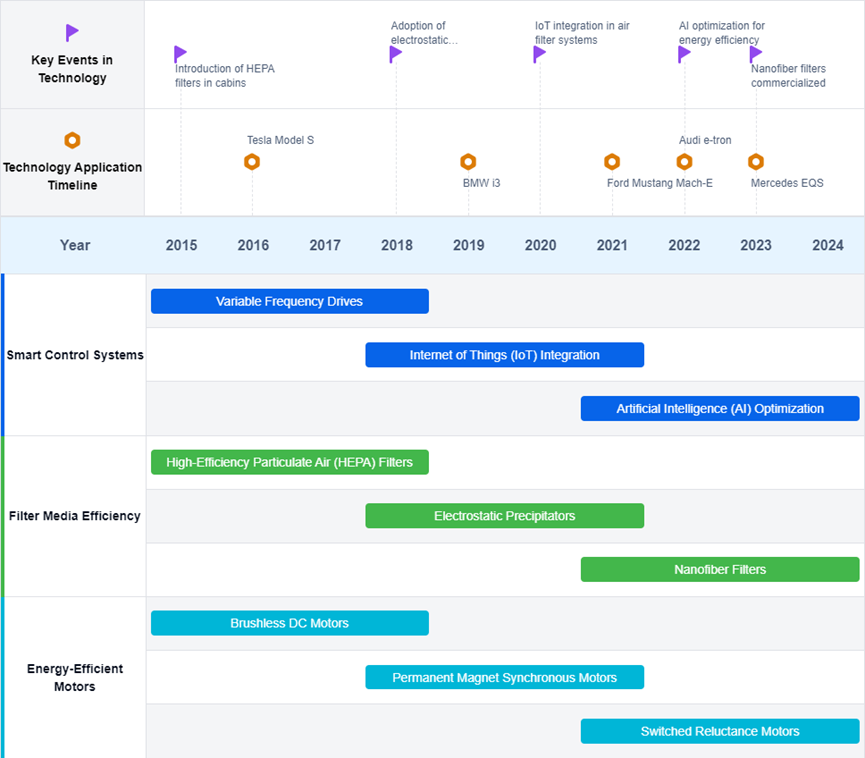

Technological advancements have focused on improving filter media, optimizing filter geometry, and integrating smart control systems. Recent developments include variable-speed fans and sensors that adjust airflow based on real-time conditions, reducing energy consumption while maintaining filtration efficiency.

The main objectives are to develop low-pressure drop filter media, optimize airflow to reduce turbulence, and incorporate intelligent control systems that adjust fan speed based on air quality. Exploring alternative technologies like electrostatic or photocatalytic filters, along with renewable energy sources, is also key. These innovations aim to create energy-efficient filtration solutions that maintain high air quality standards, contributing to a more sustainable future.

To get a detailed scientific explanations of cabin air filter, try Eureka.

Market Demand Analysis

The demand for reducing power consumption in cabin air filters is driven by multiple factors, primarily centered around regulatory pressures, consumer expectations for sustainability, and the operational needs of different vehicle types.

- Regulatory Pressures: The automotive industry is increasingly focused on improving fuel efficiency and reducing emissions due to stricter environmental regulations. Cabin air filters, while essential for maintaining air quality, can contribute to higher energy consumption, which impacts overall vehicle efficiency. Reducing power consumption in these filters helps automakers meet emission standards and improve fuel economy.

- Consumer Demand for Sustainability: Consumers are becoming more environmentally conscious, seeking vehicles that offer both high performance and minimal environmental impact. This trend has heightened the demand for energy-efficient products, including power-efficient cabin air filters, particularly in electric and hybrid vehicles where conserving battery power is critical.

- Commercial Vehicle Sector: The need for power-efficient cabin air filters is also significant in the commercial vehicle sector, including buses and trucks, which often operate for long durations. Reducing the energy consumption of these filters can lower operational costs, making these vehicles more attractive to fleet operators and logistics companies.

Current Technology Status and Challenges

Technological advancements in reducing power consumption for cabin air filters face several challenges. The key issues include balancing energy efficiency with filtration performance, space constraints in modern vehicles, the impact of varied operating conditions, and the complexity of integrating these filters with other vehicle systems.

Balancing Efficiency and Filtration

- Traditional cabin air filters use dense media to capture particulates, increasing airflow resistance and energy consumption.

- The challenge lies in balancing effective filtration with minimizing energy usage.

Space Constraints in Vehicles

- Modern vehicles have limited space for cabin air filters, restricting the size and complexity of filter designs.

- This makes it difficult to implement more efficient filters without compromising performance.

Varied Operating Conditions

- Cabin air filters must function effectively under varying temperatures, humidity, and air contaminant levels.

- These conditions can affect both filter performance and energy consumption, making consistent efficiency challenging.

System Integration Complexity

- Integrating cabin air filters with climate control and air quality monitoring systems adds complexity to energy management.

- Optimizing these systems to work together efficiently without increasing power consumption is a significant challenge.

Technology Evolution Path

Current Technical Solutions

Cabin Air Filter Design and Structure

Various designs and structures of cabin air filters aim to improve air filtration while reducing power consumption. These include multifunctional filters, filters with anion generators, photocatalytic nanofiber filters, and antimicrobial filter media.

Cabin Air Filter Design for Improved Air Filtration

This focuses on enhancing air filtration efficiency by incorporating advanced filter media, optimizing airflow paths, and improving filter geometry to capture a wide range of airborne particles, ensuring clean air inside the cabin.

Cabin Air Filter Structure for Noise Reduction

Designs aim to minimize noise levels during operation by using sound-absorbing materials, optimized airflow channels, and vibration-damping components, creating a quieter cabin environment.

Cabin Air Filter Integration with HVAC System

These filters are integrated with the HVAC system, ensuring efficient airflow, easy maintenance, and compatibility with other HVAC components for optimal performance and energy efficiency.

Cabin Air Filter Monitoring and Control Systems

Advanced systems incorporate monitoring and control features to optimize performance and reduce power consumption. This includes sensors that monitor filter condition, airflow rates, and air quality, with control systems that adjust operations based on real-time data.

Cabin Air Filter Design for Specific Applications

These filters are tailored to meet the unique requirements of specific applications, such as aircraft cabins or specialized vehicles, considering factors like cabin size, airflow needs, and operating conditions.

Key Players Analysis

The competitive landscape for reducing power consumption in cabin air filters is shaped by key players from various industries. AECC Commercial Aircraft Engine Co. Ltd., The Boeing Co., and MANN+HUMMEL GmbH lead the market with advanced filtration technologies. Companies like United Technologies Research Centre Ireland Ltd and Huawei Digital Power Technologies Co Ltd also contribute significant innovations in energy efficiency and digital power management.

- AECC Commercial Aircraft Engine Co. Ltd.: Developed advanced air filtration systems that reduce power consumption using high-efficiency particulate air (HEPA) filters and energy-efficient motors.

- United Technologies Research Centre Ireland Ltd: Introduced a novel cabin air filter system with smart sensors and adaptive control algorithms to reduce power consumption dynamically.

- Huawei Digital Power Technologies Co Ltd: Created an AI-driven, energy-efficient air filtration system that balances performance and power consumption, adapting to changing cabin conditions.

- MANN+HUMMEL GmbH: Offers nanofiber-based cabin air filters that enhance filtration efficiency while reducing airflow resistance and power consumption.

- The Boeing Co.: Developed an innovative cabin air filtration system using electrostatic precipitation to capture airborne particles, significantly reducing the power required for filtration.

Key Technology Interpretation

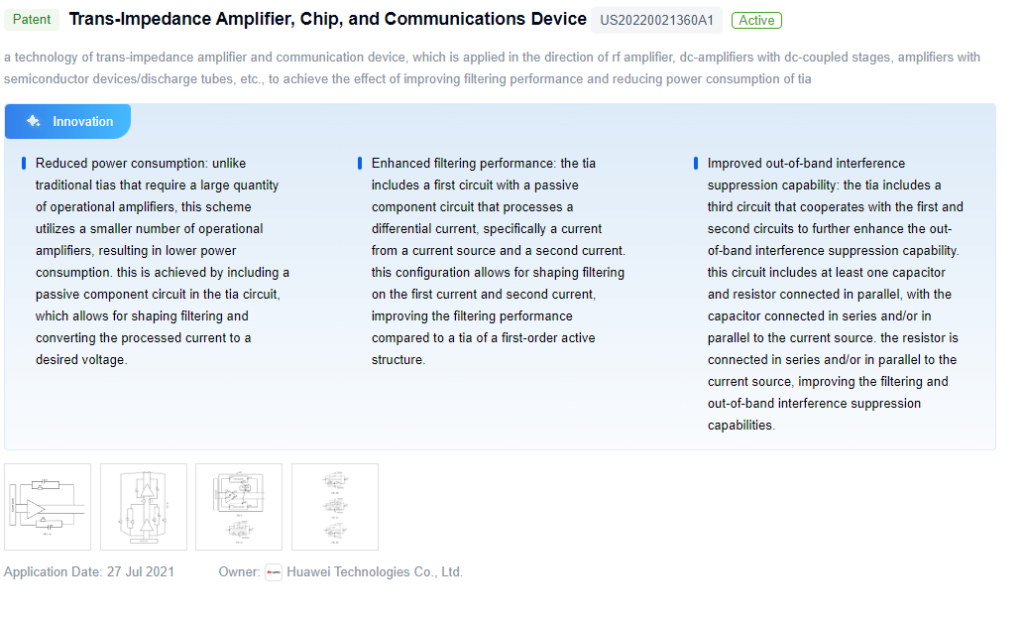

Patent 1: Trans-Impedance Amplifier Chip and Communications Device

This patent covers a trans-impedance amplifier (TIA) that reduces power consumption by utilizing fewer operational amplifiers and includes a passive component circuit for shaping and filtering currents. It also improves out-of-band interference suppression with a specialized circuit design.

Patent 2: Automatic Power Factor Correction and Data Transferring Using LoRaWAN Technology

This system uses zero-crossing detectors to monitor real-time parameters like power factor and active power. It automatically corrects the power factor using capacitor banks and transmits data over long distances with low power consumption using LoRaWAN technology.

Potential Innovation Directions

Cabin Air Filter Design for Reducing Power Consumption

Optimizing the design of cabin air filters to reduce power consumption involves minimizing pressure drop, improving airflow, and reducing resistance to air movement.

Cabin Air Filter Monitoring and Control for Power Optimization

Monitoring filter conditions and adjusting the air conditioning system accordingly can help reduce power consumption. This involves detecting when filters need replacement and optimizing airflow and fan speed based on real-time data.

Integration of Cabin Air Filtration with Energy-Efficient Systems

Integrating cabin air filtration with energy-efficient systems in vehicles can reduce overall power consumption. This includes combining filtration with heat recovery systems or using renewable energy sources to power the filtration system.

Cabin Air Filter Materials and Coatings for Power Savings

Using optimized materials and coatings in cabin air filters can reduce power consumption by minimizing resistance and static charge buildup, enhancing overall efficiency.

Energy Efficiency Standards and Regulations

Energy efficiency standards and regulations are crucial in promoting the development and adoption of technologies that reduce power consumption in cabin air filters. Regulatory bodies worldwide have implemented policies to ensure products meet certain energy efficiency criteria. Compliance with these standards is often mandatory and drives innovation in energy-efficient technologies, contributing to sustainability efforts.

Environmental Impact and Sustainability

Environmental impact and sustainability are key considerations when developing cabin air filters that reduce power consumption. Lower energy consumption leads to reduced greenhouse gas emissions and depletion of non-renewable resources. Sustainable practices should encompass the entire life cycle of cabin air filters, from material sourcing to disposal, to minimize environmental impact. Collaboration between manufacturers, researchers, and policymakers is essential to align with broader environmental goals and promote sustainable transportation solutions.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!