Rhodochrosite (MnCO₃) has captivated gemologists, mineralogists, and material scientists with its vibrant pink-to-red hues, crystalline forms, and versatile industrial uses. While gem-grade specimens have cultural and aesthetic appeal, lower-grade rhodochrosite plays a key role in manganese production and battery technology. In this post, we examine its composition, grade variations, performance traits, applications across industries, emerging processing techniques, and future outlook. Additionally, we explain how PatSnap Eureka AI Agent can help you uncover patent and innovation insights around advancements in rhodochrosite utilization.

Material Composition and Grade Data of Rhodochrosite

Rhodochrosite is a manganese carbonate mineral, typically containing trace amounts of calcium, iron, and magnesium. Its structural formula is MnCO₃. Grades include:

- Gem‑Grade (“Siberian” or “Sweet Home Mine”):

- Manganese content: ~80–90%

- Mohs hardness: 3.5–4

- Distinctive pink-to-red banding

- Use: cut gemstones, museum specimens

- Collectors’ / Faceting Grade:

- Manganese content: ~70–80%

- Medium translucency, often heated or coated

- Use: cabochons, mineral collections

- Industrial Grade:

- Manganese content: ~40–60% (with calcite or rhodochrosite gangue)

- Use: precursor for manganese metal and alloys

These grades affect color saturation, clarity, and application potential in industrial processes or gemstone uses.

Performance Characteristics of Rhodochrosite

- Chemical Composition: MnCO₃, often intergrown with calcite or siderite

- Hardness: 3.5–4 (Mohs scale) – relatively soft but suitable for careful gemstone cutting

- Specific Gravity: 3.5–3.7

- Optical Properties: Rhombohedral crystal form; translucent to transparent with distinct optical cleavage

- Thermal Sensitivity: Decomposes at ~400°C into manganese oxide and CO₂

- Electrical & Catalytic Traits: Lower-grade ore is valuable for manganese alloy manufacturing and emerging manganese‑based battery cathodes

Rhodochrosite’s Core Applications Across Industries

1. Gemstones & Jewelry

Gem-grade rhodochrosite from Argentina and Colorado features bright pink banding. Its unique coloration and ease of carving make it ideal for cabochons, pendants, and custom cuttings—especially in boutique jewelry pieces. Despite its lower hardness, careful setting and protective designs ensure long-lasting wear.

2. Collectors & Decorative Minerals

Collectors prize dendritic and stalactitic rhodochrosite specimens for display. These pieces also educate mineral enthusiasts about crystal habits and geological formation. Markets focus on rhodochrosite banded specimens and polished plate sets.

3. Manganese Ore & Alloy Production

Industrial-grade rhodochrosite ore provides a manganese source for alloying steel and aluminum. It benefits high-performance applications like vehicle chassis and pipeline components. Ongoing advancements include chemical purification to yield battery-grade manganese compounds.

4. Battery Materials & Energy Storage

Researchers are investigating rhodochrosite-derived manganese oxides as low-cost cathode materials for lithium-ion, sodium-ion, and aqueous batteries. These utilize its inherent electrochemical reactivity and redox stability, positioning rhodochrosite as a green alternative in next-gen energy storage.

5. Pigments & Coatings

Synthetic manganese carbonate, produced from processed rhodochrosite, serves as a pigment and color stabilizer in ceramics, concrete, and glass. It also contributes to corrosion inhibitors and flotation reagents in mining.

Comparative Advantages & Limitations of Rhodochrosite

| Aspect | Rhodochrosite (MnCO₃) | Calcite / Other Carbonates |

|---|---|---|

| Color & Aesthetics | Vibrant pink for gemstone use | Less appealing color variants |

| Manganese Content | High | Lower manganese content |

| Hardness | 3.5–4, gem-quality | Similar hardness |

| Battery Potential | High electrochemical reactivity | Typically inert |

| Thermal Stability | Decomposes at ~400°C | Similar decomposition range |

Limitations: Its low hardness and sensitivity to heat limit its use in high-wear or high-temp applications without processing or binding. In battery research, material consistency and impurity control remain challenges.

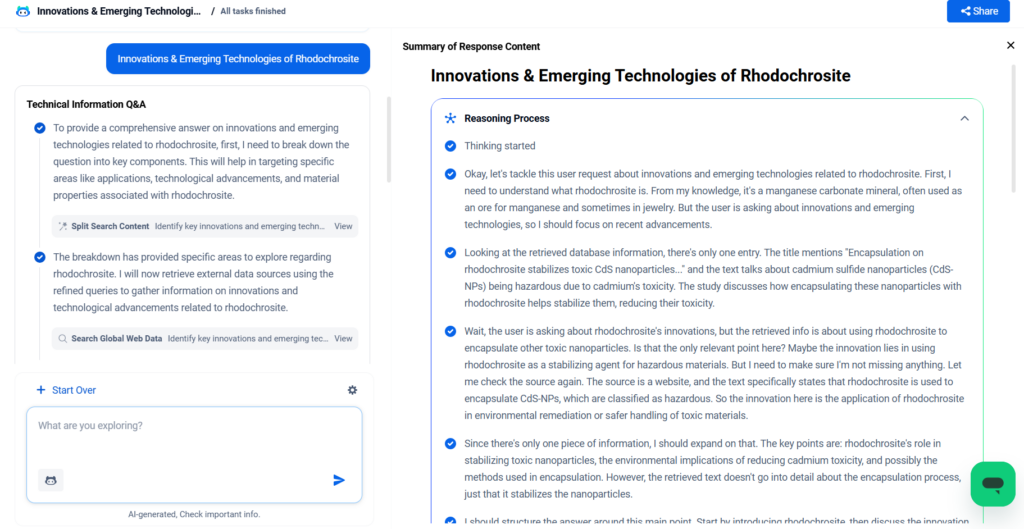

Innovations & Emerging Technologies of Rhodochrosite

Recent advancements in materials science are pushing rhodochrosite beyond its traditional geological and ornamental roles. Researchers and industry experts are exploring multiple innovative directions, particularly focused on energy, construction, and nanomaterials:

Manganese‑Based Battery Cathodes

Rhodochrosite (MnCO₃) is being transformed into nano-structured manganese oxides (MnO₂, Mn₃O₄) through controlled thermal decomposition and wet-chemical synthesis. These manganese oxides are integral to high-capacity lithium-ion and sodium-ion batteries, offering:

- Improved cycle stability due to better electrode integrity

- Higher theoretical specific capacities (up to 308 mAh/g for MnO₂)

- Lower cost than cobalt-based cathodes

Several research groups have demonstrated that rhodochrosite-derived MnO₂ can achieve over 90% coulombic efficiency after 200+ charge cycles.

Advanced Purification & Ore Beneficiation

With natural rhodochrosite containing impurities like Fe, Si, and Al, advanced purification methods are essential. Current innovations include:

- Acid leaching optimization: Reducing sulfuric acid consumption while enhancing Mn recovery rates above 94%.

- Microbubble flotation techniques: Selective removal of silicates and carbonates from low-grade ores.

These developments support sustainable sourcing of chemical-grade MnCO₃ for industrial and energy storage use.

Functional Coatings & Self‑Healing Composites

Rhodochrosite nanoparticles—coated or embedded in polymer matrices—are being tested in:

- Corrosion-resistant epoxy coatings, where Mn-based oxides passivate surface oxidation

- Self-healing concrete formulations, where carbonates aid in crack-filling via mineral recrystallization

These use cases align with green infrastructure initiatives and smart material systems.

Synthetic Crystal Cultivation for Pigment Uniformity

Hydrothermal growth techniques are now capable of producing synthetic rhodochrosite crystals with uniform color saturation and morphology. These are applied in:

- Industrial pigments (ceramics, paints, and plastics)

- Laser and optical materials, where precise lattice control is needed

Industry Challenges & Future Outlook

- Geological Supply Constraints

Major sources remain limited to Argentina and Colorado. Sustainable mining and traceability efforts are increasing in importance. - Material Stability in Service

Stone carvings require special treatments to resist weathering and sensitivity to acids. - Electrochemical Conversion Optimization

Transforming ore into battery-grade manganese oxides demands efficient scaling and process integration. - Economic Viability

Manganese battery materials must compete with widely used lithium-ion cathodes in price and performance.

Outlook: Advancements in nanostructured manganese oxides, eco-friendly purifying technologies, and synthetic crystal production could unlock new industrial and technological applications for rhodochrosite.

Conclusion

Rhodochrosite stands at the intersection of gemology, metallurgy, and sustainable energy. Its appeal ranges from museum-grade gemstones to emerging battery cathodes. As research progresses in ore purification and nanostructured manganese oxide conversion, rhodochrosite could play a pivotal role in future materials and tech systems.

FAQ

No, it is not directly used as a cathode material. However, it serves as a precursor to synthesize high-purity manganese oxides (like MnO₂), which are used in rechargeable lithium and sodium batteries.

Synthetic rhodochrosite is produced via hydrothermal or chemical vapor deposition (CVD) processes, resulting in greater control over crystal size, purity, and color. This makes it more suitable for industrial applications such as pigments or advanced optics.

While it is not yet widely used in 3D printing, research is exploring its role in ceramic-based additive manufacturing due to its carbonate structure and thermal decomposition behavior, which could aid in producing porous scaffolds or functional coatings.

Primarily the energy storage, construction, and coatings industries. Emerging applications in biomedicine and optoelectronics are also under academic investigation.

It depends on the deposit and mining practices. Innovations in ore beneficiation (e.g., selective flotation and bioleaching) and recycling of manganese-rich residues are improving environmental sustainability and material recovery rates.

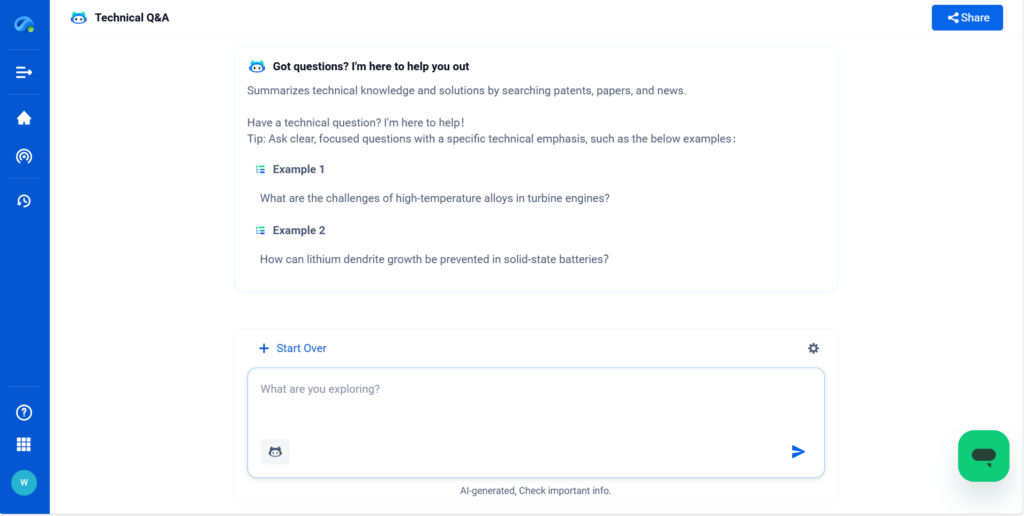

Want to uncover patent trends in manganese‑based energy storage, material coatings, or synthetic crystal methods?

PatSnap Eureka AI Agent lets you:

- Map technological clusters in rhodochrosite-based innovations

- Benchmark competitors in battery cathode research

- Discover whitespace opportunities in pigment and sustainable mining processes

👉 Start your Eureka search today and fuel your materials innovation with actionable insights.