Technical Background and Objectives

Background

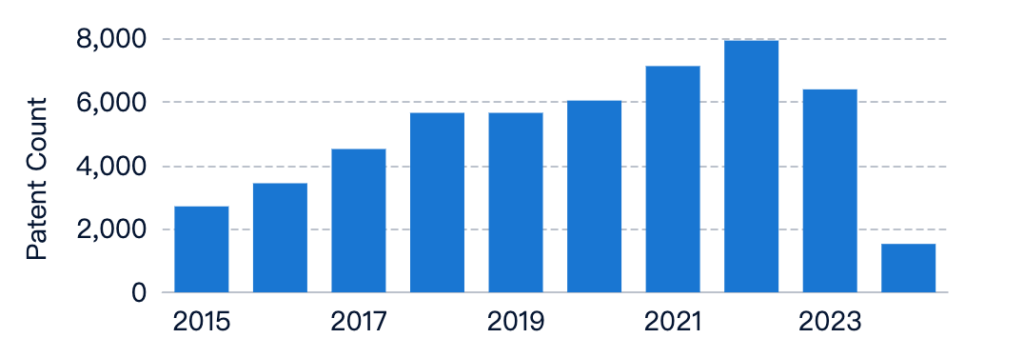

In the field of ‘robotic arms’ technology, the technical effect of ‘robotic arm simple structure’ has seen a steady increase in patent applications over the years. This upward trend reflects the growing interest and investment in simpler, efficient robotic arm designs. This movement is potentially spurred by cost reduction, manufacturing ease, and improved versatility.

Contrastingly, the literature publication data shows a more volatile pattern. Initial growth was followed by a decline, then a recent revival. This fluctuation may stem from research maturation, focus shifts, or new challenges/opportunities sparking academic interest. Despite these variations, the consistent patent filing rise indicates a robust industry motivation to develop simplified robotic arms.

Objectives

The primary objective is to develop a simple and cost-effective robotic arm structure. This trend could be driven by the growing demand for robotic solutions across various sectors, including manufacturing, healthcare, and service industries, where simplicity and cost-effectiveness are desirable attributes.

To get a detailed scientific explanations of robotic arms, try Eureka.

Technical Current Status Analysis

Robotic Arms

Robotic arms are widely used in various industries, such as manufacturing, assembly, material handling, and even medical and surgical operations. They offer advantages such as high precision, repeatability, and the ability to perform tasks in hazardous or inaccessible environments.

Applications and Impact:

- Manufacturing: Simpler robotic arms lower costs, boost reliability, and simplify maintenance for SMEs.

- Assembly/Packaging: Simpler designs accelerate assembly, sorting, and palletizing with lower failure risks.

- Medical/Surgical: Simpler robotic arms cut costs and complexity for minimally invasive procedures.

- Service Robotics: Simpler arms enable more affordable and easier robots for tasks like cleaning, inspection, and maintenance.

Technical Characteristics and Challenges:

- Degrees of freedom (DOF): Balancing simplicity and dexterity in robotic arm design is key for specific applications.

- Payload capacity and reach: Simpler designs limit payload and reach, restricting use in heavy-load or hard-to-reach tasks.

- Precision and repeatability: Simplified structures face challenges in maintaining precision and repeatability.

- Control & Programming: Innovative control and programming required for simpler robotic arms.

- Modularity & Reconfigurability: Modular designs enhance adaptability while maintaining simplicity.

- Cost & Manufacturability: Simplification should not compromise cost-effectiveness or manufacturability.

Technological Paths:

- Optimized kinematic design: Identify optimal joint/link config for apps, balancing simplicity & performance.

- Parallel and hybrid mechanisms: Increase stiffness, payload, workspace with simple structure.

- Compliant and underactuated mechanisms: Reduce actuators, rely on passive compliance for motions.

- Advanced materials and manufacturing techniques: Use composites, alloys, additive manufacturing for optimized arms.

- Intelligent control and programming: Develop adaptive, ML, task-optimized algos to compensate for limitations.

- Modular and reconfigurable design: Adapt/expand arm for different apps with simple core components.

Research Content

Research Objectives

Discover the innovative and cost-effective robotic arm structure in our technical report. Simplifying design and construction for widespread adoption in industrial and commercial applications.

Research Direction and Focus

Structural Design and Kinematics

- Optimal Structural Design: Analyzing materials, joint types, and actuation mechanisms for lightweight, durable designs.

- Kinematic Configuration: Providing necessary range of motion and dexterity.

Control Systems and Automation

- Robust Control Systems: Exploring control architectures, sensor integration, and programming techniques.

- User-Friendly Interfaces: Developing intuitive interfaces and automation features.

Integration and Testing

- Mounting Solutions: Designing compatible mounting solutions.

- Performance Evaluation: Conducting extensive testing to evaluate performance, reliability, and safety.

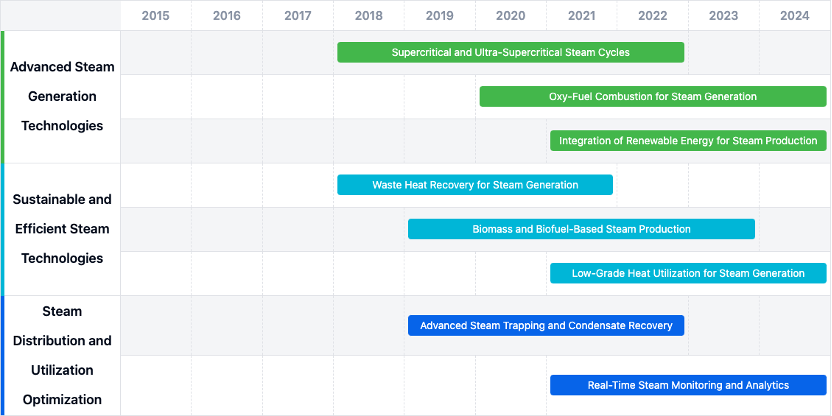

Technical Development Roadmap

Key Areas of Advancement

- Actuation technologies have advanced from electro-hydrostatic to servo-hydraulic and soft robotic mechanisms, enabling precise, responsive motion.

- Sensing & control systems have improved with multi-modal sensor fusion, machine learning, and haptic feedback, enhancing dexterity in complex environments.

- Robotic arm design & manufacturing have been revolutionized by lightweight materials, modular architectures, and additive manufacturing, resulting in agile, versatile, and intelligent robotic arm systems.

Main Player Analysis

Key Players and Focus

- Cilag GmbH International: Focus on innovative solutions for robotic arm mechanisms.

- Applied Materials Inc.: Emphasis on scalability and adaptability in robotic arm designs.

- Ethicon LLC: Focus on robotic arm designs for medical and surgical applications.

Current Technical Solution Overview

Simple and Practical Robotic Arm Structure

- Lightweight Structures: Simple, lightweight designs for desktop or tabletop applications.

- Modular and Reconfigurable Designs: Easy assembly, disassembly, and customization.

- Compact and Space-Saving: Folding or collapsible mechanisms.

- Improved Dexterity and Range of Motion: Additional joints and articulated links.

- Integrated Safety Features: Collision detection and emergency stop mechanisms.

Robotic Arm for Medical and Surgical Applications

- Precise Positioning and Movement: Tailored for surgical settings.

- Mounting and Interfacing: Secure attachment and alignment with surgical systems.

- Control Systems: Advanced control algorithms for precise operation.

- Specialized Designs: Tailored for specific surgical applications.

Robotic Arm for Industrial and Specialized Applications

- Advanced Motion Control: High accuracy and dexterity.

- Modular Structures: Easy customization for different tasks.

- Wearable and Portable Designs: Ergonomic operation in confined spaces.

Robotic Arm with Modular or Foldable Design

- Modular Design: Reconfiguration and easy maintenance.

- Foldable Structure: Compact and portable.

- Desktop and Compact Designs: Suitable for educational and hobbyist applications.

- Simplified Joint Configurations: Optimized for specific applications.

Robotic Arm with Desktop or Compact Configuration

- Desktop Robotic Arm: Small footprint for limited spaces.

- Simplified Driving Mechanisms: Rotary tables and linear actuators.

- Modular and Reconfigurable Designs: Customization and maintenance.

- Lightweight and Portable: Ease of use and maneuverability.

- Simplified Joint Configurations: Reduced degrees of freedom for specific tasks.

Key Patent Interpretation

Patent Highlights

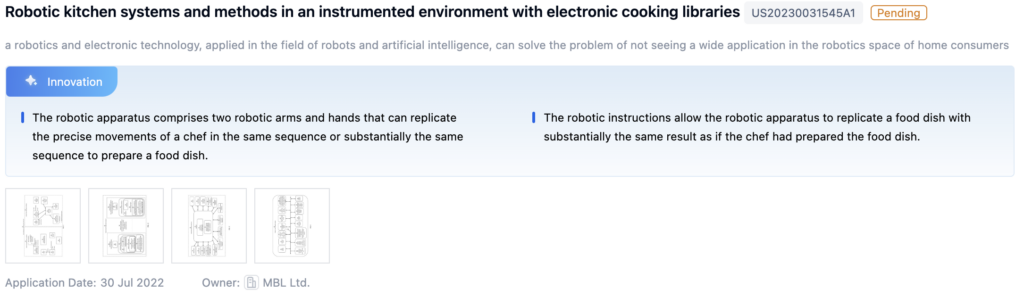

Patent 1: Robotic Kitchen Systems and Methods

- Core Invention Points:

- Replicates chef’s movements to prepare food.

- Replicates a food dish with the same result as a chef.

Patent 2: Method of Robotic Hub Communication Detection and Control

- Core Invention Points:

- Adaptive control schemes and situational awareness.

- Wireless pairing and smart activation of surgical devices.

Patent 3: Cooperative Surgical Actions for Robot-Assisted Surgical Platforms

- Core Invention Points:

- Cooperative movement of two robotic arms based on force sensor inputs.

Possible Research Directions

- Simple Robotic Arm Structure: Simplified design with fewer components for ease of manufacture and operation.

- Robotic Arm for Surgical Tables: Assisting in medical procedures with precise positioning and movement capabilities.

- Desktop Robotic Arm Structure: Compact and lightweight for educational and hobbyist use.

- Robotic Arm Positioning and Control: Techniques for aligning and controlling robotic arm movement.

- Robotic Arm Integration with Vehicles: Assisting in tasks like material handling and exploration.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!