Shear stress plays a critical role in material science, engineering, and physics. It refers to the force per unit area exerted parallel to the surface of a material, causing it to deform. Engineers and scientists rely on Tangential stress to design structures that can withstand forces without failing. This article explores the fundamentals of Tangential stress, its applications, and its significance across various industries like construction, manufacturing, and biomechanics.

What is Shear Stress?

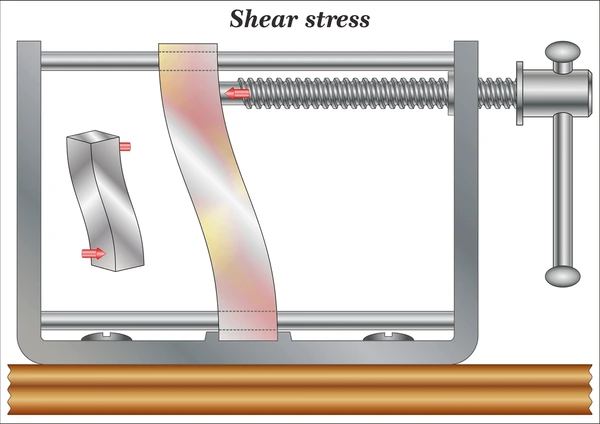

Shear stress occurs when an external force acts parallel or tangential to a surface, causing one layer of material to slide over another. The force divides by the area over which it distributes, resulting in the Tangential stress value.

Key Characteristics:

- Forces act parallel to the surface

- Deforms material through sliding

- Affects internal structure and material stability

The Mechanics of Shear Stress

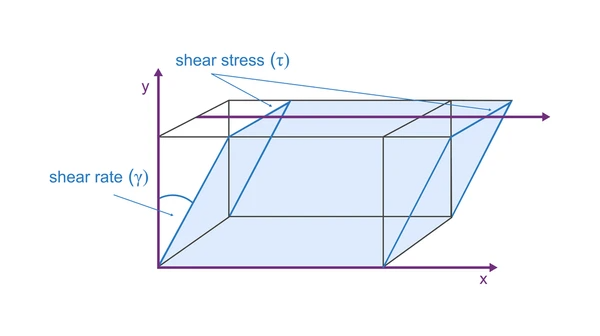

- Formula: Shear stress (τ) equals the applied force divided by the area over which the force applies:τ=FA\tau = \frac{F}{A}τ=AFwhere F is the applied force, and A is the area.

- Shear Strain: The material’s response to Shear force per unit area, called shear strain, measures the displacement between layers under stress.

- Elastic vs. Plastic Deformation: Shear force per unit areacan cause either elastic deformation (temporary) or plastic deformation (permanent), depending on the magnitude of the force and the material’s properties.

Types of Shear Stress

- Simple Shear Stress: Occurs when one material layer slides over another with force acting parallel to the surface.

- Shear Stress in Torsion: Happens when rotational force (torque) applies to an object like a shaft, inducing this stress along the material’s surface.

- Shear Stress in Bending: Results when beams or structures bend under load, creating shear forces at various points.

Applications of Shear Stress in Engineering and Material Science

Shear stress plays a pivotal role in the behavior of materials. Its influence extends to multiple sectors:

- Civil Engineering: Shear force per unit area impacts the strength and stability of beams, columns, and foundations. Engineers must consider it in their designs to ensure that structures bear loads without failure.

- Manufacturing: In metalworking, Shear force per unit area influences processes like cutting, forging, and machining. Manufacturers optimize these processes based on how materials respond to shear forces.

- Biomechanics: In human joints and tissues, Shear force per unit area helps researchers study how forces affect bones and cartilage. Understanding this allows for better prosthetic design and improved medical treatments.

Performance Comparison: Materials Under Shear Stress

| Material | Shear Strength | Elastic Deformation | Plastic Deformation | Best Use Case |

|---|---|---|---|---|

| Steel | High | Moderate | High | Structural components |

| Aluminum | Moderate | High | Moderate | Aircraft parts |

| Rubber | Low | High | Low | Seals and gaskets |

| Concrete | Low | Low | High | Construction |

Steel’s high shear strength makes it ideal for structural applications, while rubber offers flexibility under shear forces.

Challenges and Limitations of Shear Stress in Engineering

💡 Facing challenges in understanding shear stress in engineering? Eureka Technical Q&A provides expert solutions and in-depth analysis, helping you navigate complex topics like shear force distribution, material limitations, and stress testing to optimize your designs and improve structural integrity.

- Material Failure: When Shear force per unit area exceeds a material’s shear strength, it can cause fractures or cracks.

- Complexity in Analysis: Engineers must accurately predictShear force per unit area in real-world conditions, especially when structures face dynamic loads.

- Fatigue: Repeated Shear force per unit area can lead to material fatigue, causing failure over time, even under forces below the material’s ultimate strength.

The Future of Shear Stress Research and Innovations

- Nanoengineering: Engineers are discovering new materials at the nanoscale that exhibit unique Shear force per unit area properties, leading to stronger and more durable products.

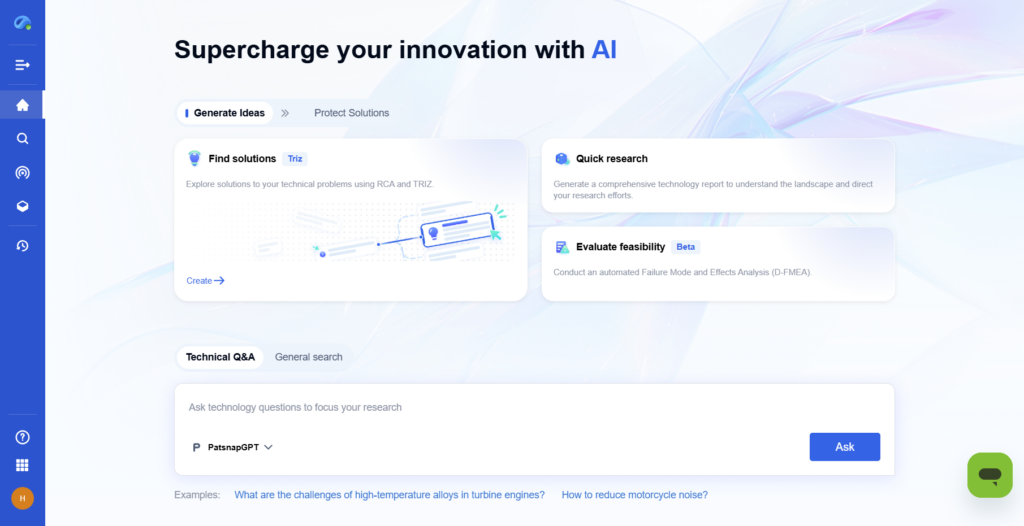

- AI and Simulation: Artificial intelligence helps researchers simulate how materials respond to Shear force per unit area under various conditions, improving design accuracy.

- Composite Materials: Researchers are developing composites with enhanced shear strength, which could revolutionize aerospace and automotive industries.

How Eureka by PatSnap Enhances Shear Stress Research and Development

What is Eureka by PatSnap?

Eureka by PatSnap is an AI-powered research tool that helps engineers discover cutting-edge materials and technologies related to Shear force per unit area.

How Eureka Supports Shear Stress Research

- Patent Insights: Eureka tracks the latest patents for materials designed to resist Shear force per unit area.

- Competitive Intelligence: The platform helps manufacturers stay competitive by analyzing Shear force per unit area technologies.

- Technology Roadmapping: Eureka provides insights into emerging trends in Shear force per unit area research, from nanotechnology to smart materials.

Conclusion

Shear stress plays a crucial role in material science and engineering, influencing how materials behave under external forces. Understanding its effects helps in designing stronger, more durable materials for various applications. With advancements in technology and material science, researchers continue to improve how we manage this stress, leading to stronger and more efficient structures, devices, and products.

FAQs

1️⃣ What causes material failure due to shear stress?

Material failure occurs when the applied this stress exceeds the material’s shear strength, leading to cracks or fractures.

2️⃣ How does shear stress affect building design?

Engineers must account for this stress to ensure structures remain stable and functional under various loading conditions.

3️⃣ Can we minimize shear stress in materials?

Yes, materials with high shear strength, like steel and composites, are designed to withstand greater shear forces, reducing failure risk.

4️⃣ What is shear fatigue?

Shear fatigue happens when repeated it weakens materials over time, even when forces remain below the material’s maximum strength.

5️⃣ How is shear stress measured in materials?

It is calculated by dividing the applied force by the area over which the force is distributed using the formula τ = F/A.

To get detailed scientific explanations of Shear Stress, try Patsnap Eureka.