The internal combustion engine has powered vehicles and machinery for over a century, and one of its most widely used types is the spark ignition (SI) engine. Found in everything from motorcycles and passenger cars to small generators and power tools, SI engines are known for their efficiency, simplicity, and responsiveness.

This article explains what an SI engine is, how it works, its key components, and the practical uses that make it a staple in modern engineering.

What Is an SI Engine?

What is an SI engine? Eureka Technical Q&A explains that a Spark Ignition (SI) engine ignites an air-fuel mixture using a spark plug, commonly found in gasoline-powered vehicles for efficient and smooth combustion.

An SI engine, or spark ignition engine, is a type of internal combustion engine where the air-fuel mixture is ignited by a spark plug. This distinguishes it from compression ignition (CI) engines, such as diesel engines, where ignition occurs due to high pressure and temperature.

SI engines typically operate using petrol (gasoline), compressed natural gas (CNG), or liquefied petroleum gas (LPG). The most common application of SI engines is in gasoline-powered vehicles.

How Does a Spark Ignition Engine Work?

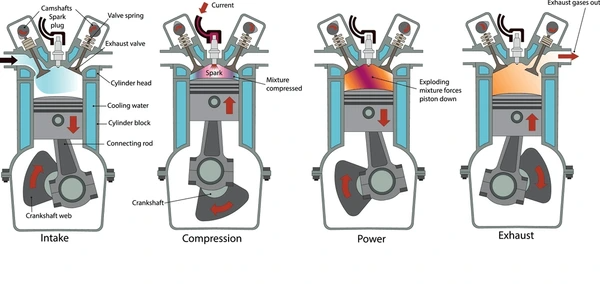

SI engines operate in cycles, with the four-stroke cycle being the most common. The process involves:

- Intake Stroke

The intake valve opens, allowing a fuel-air mixture to enter the cylinder as the piston moves downward. - Compression Stroke

The valves close, and the piston moves up, compressing the mixture. - Power (Combustion) Stroke

A spark plug ignites the compressed mixture, causing an explosion that pushes the piston down, generating power. - Exhaust Stroke

The piston rises again, expelling exhaust gases through the open exhaust valve.

This cycle repeats rapidly, converting chemical energy in fuel into mechanical energy to drive the engine.

Key Components of an SI Engine

- Spark Plug: Initiates combustion at the right moment using an electrical spark

- Carburetor or Fuel Injector: Mixes fuel with air in correct proportions

- Piston and Cylinder: Translates combustion energy into motion

- Crankshaft: Converts piston movement into rotary motion

- Valves: Control intake and exhaust timing

- Cooling and Lubrication Systems: Maintain optimal temperature and reduce wear

Characteristics of SI Engines

- Operate at moderate compression ratios (8:1 to 12:1)

- Quieter than diesel engines

- Generally lighter and more compact

- Require spark timing and air-fuel mixture control

- Often used with manual or automatic ignition timing systems

Applications of SI Engines

Automotive Vehicles

Most passenger cars and motorcycles use SI engines due to their smooth operation and rapid throttle response. Hybrid electric vehicles also use SI engines in conjunction with battery systems.

Small Engines

Lawn mowers, chainsaws, and portable generators commonly rely on compact SI engines for reliable, user-friendly power.

Light Commercial Vehicles

SI engines are used in delivery vans, taxis, and ride-share vehicles in regions with clean fuel infrastructure.

Aviation and Sports

Some small aircraft and recreational vehicles like ATVs and snowmobiles use high-performance SI engines.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Variable Energy Ignition System Cummins, Inc. | Dynamically adjusts ignition energy based on fuel quality and ignitor characteristics, improving engine performance and extending ignitor life. | Spark-ignition engines with varying fuel quality and operating conditions. |

| Lean-Boost Spark Ignition Engine GM Global Technology Operations LLC | Achieves peak indicated thermal efficiency under λ=1.3 with intake manifold absolute pressure of 150 kPa, improving fuel efficiency without power penalty. | High-efficiency spark ignition engines for automotive applications. |

| Closed Loop Combustion Control System Woodward, Inc. | Uses spark plug to detect ionization signals and adjust ignition timing, preventing incipient knock and enhancing engine efficiency and safety. | Lean-burn reciprocating engines requiring precise combustion control. |

| Passive SCR Aftertreatment System GM Global Technology Operations LLC | Integrates passive SCR with three-way catalytic converter and ammonia-selective catalytic reduction catalyst, allowing controlled transitions between HCCI and SI modes. | Direct-injection engines requiring efficient fuel use and reduced emissions. |

| Pulsed Microwave Plasma Ignition System West Virginia University | Produces sufficiently energetic microwave discharges in a short time frame, offering potential advantages over traditional spark plugs. | SI engines operating with lean fuel-air mixtures and at higher power densities and pressures. |

SI Engine vs CI Engine

Spark-ignition (SI) and compression-ignition (CI) engines power most of today’s vehicles and machinery. While both operate on internal combustion principles, they differ significantly in how they ignite fuel, manage emissions, and serve industrial applications.

Combustion Process

SI engines ignite a premixed air-fuel blend using a spark plug. First, the engine draws in the mixture. Then, it compresses and ignites it with a spark, which creates flame propagation.

CI engines ignite fuel differently. They compress air to high temperatures and inject fuel, which ignites spontaneously. This auto-ignition process eliminates the need for a spark plug.

Efficiency and Emissions

SI engines operate with lower compression ratios and a stoichiometric fuel mix. As a result, they deliver less thermal efficiency but emit fewer nitrogen oxides. They also run more quietly in most applications.

CI engines run at higher compression ratios and use lean-burn strategies. This improves efficiency but increases emissions like NOx and particulates. Therefore, they often require complex emission control systems.

Common Applications

Automakers often use SI engines in passenger cars due to their smoothness and lower emissions at light loads. These engines also suit high-speed applications like motorcycles and sports vehicles.

CI engines dominate heavy-duty sectors. You’ll find them in trucks, trains, marine vessels, and even aircraft. Their higher torque and fuel efficiency make them ideal for demanding conditions.

Recent Advancements

Engineers continue exploring hybrid designs to combine the strengths of both engine types. One promising innovation is Homogeneous Charge Compression Ignition (HCCI), which offers better fuel efficiency and lower emissions.

Another innovation is Gasoline Compression Ignition (GCI), which blends diesel-like efficiency with gasoline’s cleaner burn. This approach could offer the best balance between power and sustainability.

| Feature | SI Engine | CI Engine |

|---|---|---|

| Ignition Method | Spark plug | Compression ignition |

| Common Fuel | Gasoline, CNG, LPG | Diesel |

| Compression Ratio | Lower (8:1 to 12:1) | Higher (14:1 to 22:1) |

| Noise and Vibration | Lower | Higher |

| Efficiency | Moderate | High |

| Maintenance Cost | Generally lower | Generally higher |

| Application | Cars, bikes, small equipment | Trucks, buses, heavy machinery |

Advantages of Spark Ignition Engines

- Quick start-up even in cold conditions

- Smooth and quiet operation

- Lower weight and compact size

- Widespread fuel availability

- Easier maintenance compared to diesel engines

Limitations to Consider

- Less efficient at higher loads

- More emissions of carbon monoxide and hydrocarbons

- Cannot use high-compression ratios due to knocking risk

- Typically lower torque than diesel engines at low speeds

FAQs

What fuels can SI engines use?

Primarily gasoline, but also LPG and CNG with suitable modifications.

Can an SI engine run without a spark plug?

No. The spark plug is essential for igniting the air-fuel mixture.

Why are SI engines common in cars?

They offer a good balance of performance, efficiency, and ease of use for everyday driving.

Do SI engines require regular tuning?

Yes. Periodic spark plug replacement, fuel system cleaning, and ignition timing checks are important for performance.

Is knocking more common in SI engines?

Yes. Knocking can occur if the fuel-air mixture detonates prematurely, especially with low-octane fuel.

Conclusion

Spark ignition engines remain an essential part of modern transportation and machinery. With their smooth operation, quick throttle response, and compatibility with various fuels, SI engines continue to serve in a wide range of applications. Understanding how they work and where they’re most effective helps engineers, mechanics, and everyday users make informed choices about performance, efficiency, and maintenance. Whether powering a family sedan or a portable generator, the SI engine is a proven and trusted technology.

To get detailed scientific explanations of SI Engine, try Patsnap Eureka.