As the global shift to renewable energy accelerates, solar inverters have become a crucial enabling technology in photovoltaic (PV) systems. These devices convert the DC output of solar panels into AC electricity, suitable for grid use or standalone systems. Beyond simple conversion, modern inverters optimize energy yields, provide grid services, and integrate with battery systems. This blog examines the material composition, performance grades, and cross-sector applications of solar inverters, with insights tailored for engineers, system designers, and sourcing professionals through PatSnap Eureka AI Agent.

What is a Solar Inverter and Why It Matters

A solar inverter is an electronic device that converts the direct current (DC) generated by solar modules into alternating current (AC), the form used by most electrical grids and appliances. It is central to energy harvesting, ensuring efficient, stable, and grid-compliant operation. In addition to conversion, inverters now incorporate:

- Maximum Power Point Tracking (MPPT)

- Anti-islanding protection

- Remote monitoring and diagnostics

- Battery management and hybrid energy control

These expanded roles make inverters critical in residential, commercial, utility-scale solar, and microgrid applications.

Grades vary based on inverter type (string, central, or micro), power class (1 kW to >1 MW), and deployment environment (indoor, rooftop, utility-scale outdoor).

Performance Characteristics

- Conversion Efficiency: Up to 99% in high-end SiC-based designs.

- MPPT Range: 100–1000 V DC depending on inverter class.

- THD (Total Harmonic Distortion): <3% for grid compliance.

- Thermal Conductivity: >4 W/mK for TIMs, ensuring reliable thermal management.

- Ingress Protection (IP): IP65–IP68 for outdoor-rated enclosures.

- Operating Life: >15–20 years with MTBF over 100,000 hours.

Advanced SiC-based modules offer higher switching frequencies (up to 150 kHz), lower conduction losses, and compact form factors.

Core Applications Across Industries

1. Residential Rooftop Systems

String and microinverters are used in rooftop PV systems, with Enphase and SolarEdge leading innovations in module-level optimization and smart monitoring.

2. Commercial & Industrial (C&I) Installations

Central and multi-string inverters handle high voltage input (>1000 VDC), enabling building-scale PV integration with BMS and SCADA interoperability.

3. Utility-Scale Solar Farms

High-power central inverters (500 kW to 5 MW) dominate here, integrated with MV transformers and trackers. Sungrow, SMA, and Huawei offer advanced grid-support functions including voltage ride-through (VRT) and reactive power control.

4. Microgrids & Hybrid Energy Systems

Bi-directional inverters manage solar, diesel, wind, and battery inputs, enabling off-grid autonomy or grid-tied peak shaving. Use cases include military bases, island electrification, and disaster recovery setups.

5. EV Charging Infrastructure

Inverters serve as DC-AC interface layers for solar-integrated EV charging, supporting vehicle-to-grid (V2G) functions and energy arbitrage in smart grids.

Comparative Advantages and Limitations

Advantages

| Advantage | Description |

|---|---|

| High Conversion Efficiency | Modern solar inverters achieve up to 99% peak efficiency, especially with SiC (Silicon Carbide) and IGBT (Insulated Gate Bipolar Transistor) technologies, reducing energy losses during DC-to-AC conversion. |

| MPPT Precision & Dynamic Response | Advanced Maximum Power Point Tracking (MPPT) algorithms rapidly adjust to changes in irradiance and temperature, ensuring maximum yield even under partial shading or cloud intermittency. |

| Scalability Across Deployment Scenarios | Inverters are modular and come in a wide range of ratings—from microinverters (<1 kW) for residential rooftops to central/utility-scale (>5 MW) for solar farms, allowing tailored design per application. |

| Digitalization & Grid Support | Integration of advanced telemetry, IoT protocols, and AI-based analytics enables features such as real-time power quality monitoring, fault prediction, and grid-forming capability for microgrid support. |

| Modular Architecture for O&M | Many modern inverters are designed with hot-swappable components (e.g., power stages, fans), allowing for on-site diagnostics, reduced downtime, and lower O&M costs. |

| Low THD Output | High-performance inverters with pulse-width modulation (PWM) and LCL filters minimize Total Harmonic Distortion (<3%), ensuring compatibility with sensitive loads and reducing grid interference. |

Limitations

| Limitation | Description |

|---|---|

| Thermal Management Complexity | High switching frequencies (esp. in SiC/GaN-based inverters) result in localized hotspots, necessitating multi-phase cooling, heat pipes, or liquid cooling systems—increasing design and maintenance burden. |

| Harmonic & EMI Compliance | Meeting IEEE 519, IEC 61000-4-15, or national harmonic emission standards often requires active filtering and careful PCB layout, particularly for grid-tied systems. |

| High Initial CapEx | SiC-based inverters, although efficient, still have ~2–3× higher component cost compared to traditional Si-based ones. Payback is longer without sufficient energy throughput or grid service monetization. |

| Component Aging & Reliability | Electrolytic capacitors, cooling fans, and relays are subject to thermal fatigue, dry-out, and mechanical wear—with typical service lives of 5–10 years, shorter than PV module lifespan. |

| Cybersecurity Risks | With increasing digitization and remote connectivity (via Modbus, Ethernet, WiFi), inverters are now vulnerable to firmware attacks, making OTA updates and encryption protocols critical for resilience. |

| Partial Shading Sensitivity in String Configurations | Without module-level electronics (e.g., power optimizers or microinverters), string inverters may exhibit yield losses from localized shading or cell mismatch. |

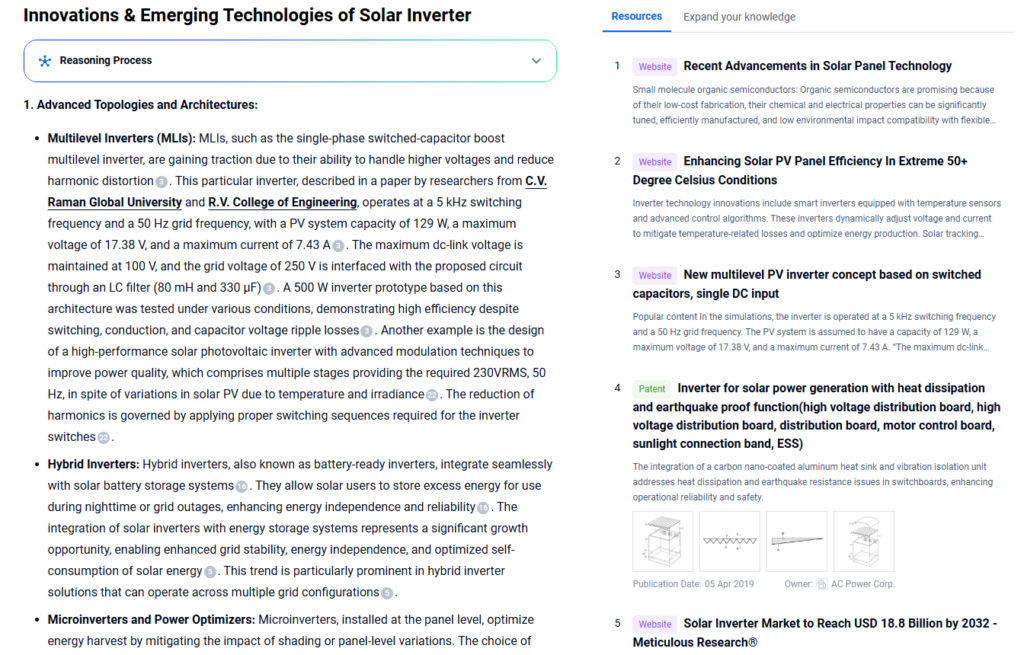

Innovations & Emerging Technologies of Solar Inverter

| Technology | Description | Maturity Level |

|---|---|---|

| Wide Bandgap (WBG) Semiconductors: SiC & GaN | Enable ultra-high frequency switching (up to MHz), reduced size, and higher junction temperatures (up to 200°C), leading to compact, fanless inverter designs. Ideal for aerospace, EVs, and constrained rooftops. | Commercial Deployment |

| AI-Powered MPPT & Load Forecasting | AI algorithms dynamically adjust MPPT under cloud transients, module soiling, and horizon shading. Coupled with machine learning on irradiance profiles and load curves, these maximize net yield. | Early Commercial |

| Digital Twin & Predictive O&M | Digital replicas of inverters track real-time temperature, switching cycles, and harmonic content, enabling RUL (Remaining Useful Life) estimation and anomaly detection before fault occurs. | Growing Adoption |

| Hybrid Inverters with Embedded BMS | Inverters like SolarEdge Energy Hub or Huawei SUN2000 integrate bi-directional storage management, real-time SoC/DoD monitoring, and V2H/V2G readiness for smart grid interaction. | Commercial |

| Printed Circuit Heat Sinks (PCHS) | Replace conventional metal sinks with integrated copper-layered PCBs, enhancing thermal pathways and enabling thinner, lighter inverter assemblies. This improves power density and reduces weight. | Niche Adoption |

| Blockchain-Integrated Inverter Protocols | Emerging models link inverters to blockchain-enabled energy trading platforms, allowing peer-to-peer energy sales and grid flexibility market participation. Key in virtual power plants (VPPs). | Pilot Projects |

| Solid-State Transformer (SST)-Ready Designs | Preparing inverter platforms for integration with SSTs, which enable bidirectional power flow, voltage regulation, and multi-port energy routing (solar, EV, storage). | R&D & Pilots |

Challenges and What’s Next for Solar Inverters

The path forward for solar inverters involves addressing:

- Grid Interoperability: Adapting to evolving grid codes and supporting ancillary services.

- Cybersecurity: As inverters become networked, they are vulnerable to intrusion.

- Raw Material Volatility: Prices of semiconductors and rare earths can impact inverter costs.

- Recyclability: Designing for disassembly and end-of-life circularity remains limited.

Future advancements will focus on AI-enabled power electronics, ultra-high-voltage PV string compatibility (>1500V), and edge-computing enhanced energy dispatch.

Conclusion

Solar inverters are not just conversion tools—they are the digital brains of PV systems. With high-efficiency SiC and GaN modules, smart algorithms, and hybrid energy capabilities, they define solar system performance and reliability. For procurement teams, engineers, and innovators, understanding inverter materials and architectures is key to optimizing value and lifespan.

FAQs

A1: Most inverters last 10–20 years, with high-end models exceeding 25 years under optimal conditions.

A2: Microinverters are attached to individual solar panels for localized conversion and monitoring, while string inverters handle a group of panels collectively.

A3: For high-performance or space-constrained applications, SiC inverters offer better efficiency, thermal tolerance, and lifespan, justifying the upfront cost.

A4: Yes, hybrid and bi-directional inverters can operate in off-grid or islanded modes, often integrated with battery storage.

Want to uncover innovation trends, IP portfolios, or emerging suppliers in solar inverter technologies?

👉 Explore deeper insights using PatSnap Eureka AI Agent to gain instant technical insights, benchmark innovators, and accelerate sourcing and design decisions with confidence.